Motor equipment full life-cycle management data acquisition system

A technology of full life cycle and data management, applied in the field of motor equipment life cycle management data acquisition system, can solve the problems of no temperature vibration measurement analysis, unable to locate the motor health status, waste of manpower and material resources, etc., to achieve manpower saving, economical The effect of saving and saving bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

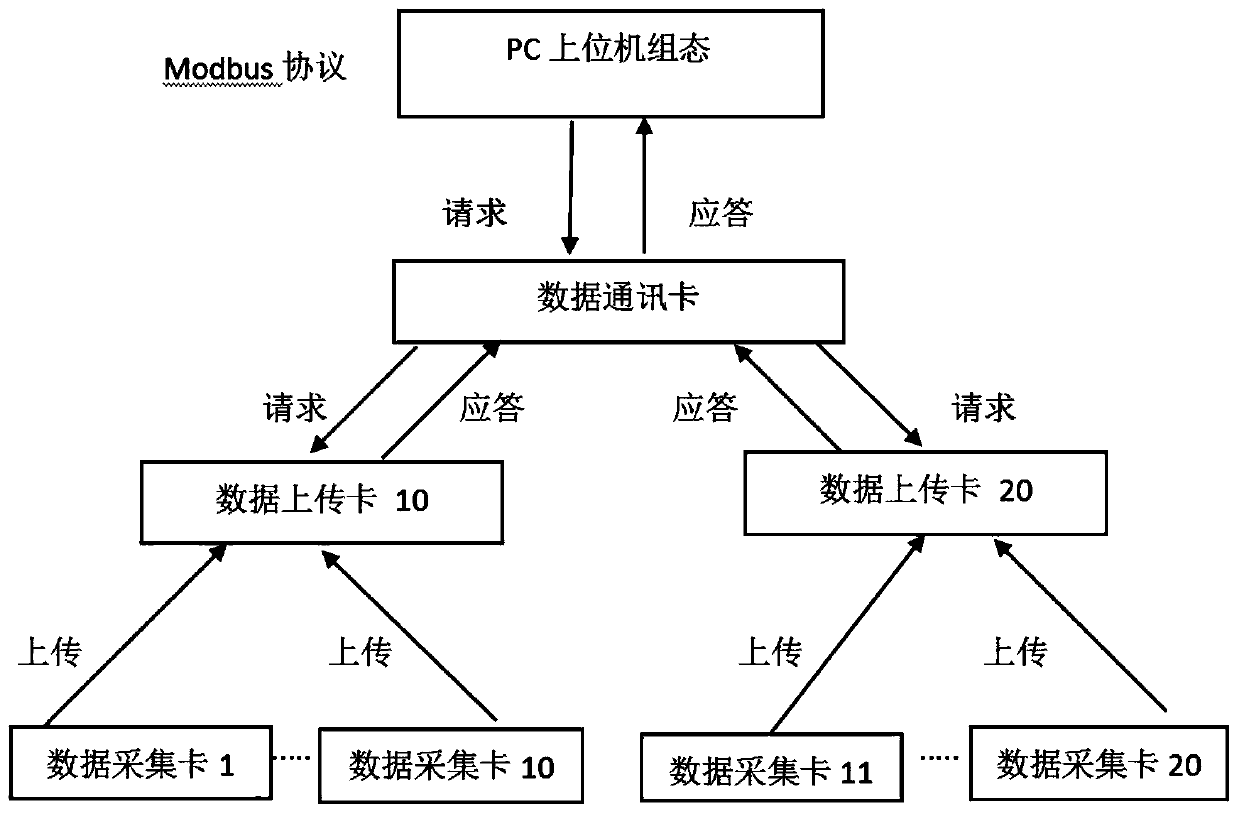

[0025] Such as figure 1 As shown, a data acquisition system for the whole life cycle management of electrical equipment includes a three-layer structure, the first layer is an acquisition card, the second layer is a data upload card, and the third layer is a data communication card.

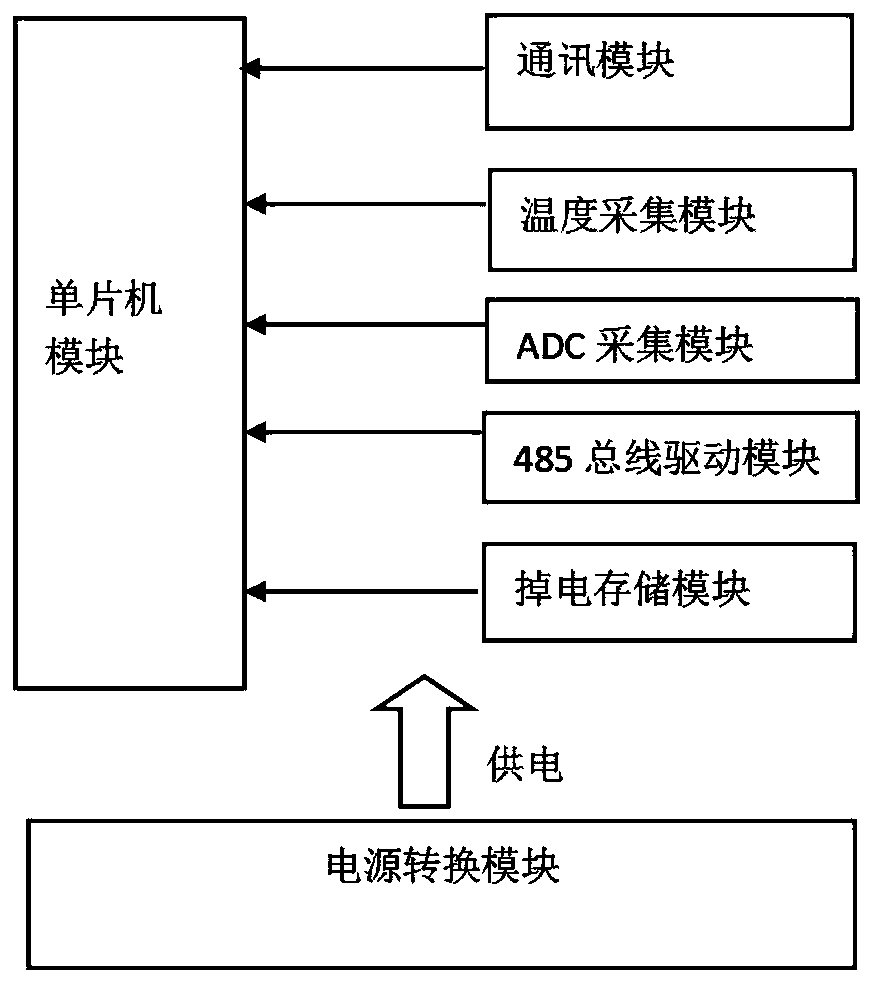

[0026] The acquisition card includes multiple, taking 20 motors as an example, there are 20 acquisition cards, and each acquisition card is responsible for collecting the current, temperature, and vibration signal of a single motor, and after the data is intelligently screened, it is sent to the second-layer data Upload card.

[0027] Described data uploading card comprises a plurality of, and acquisition card is divided into multiple groups, figure 1 The embodiment is divided into 2 groups, each group has 10 acquisition cards, and there are 2 data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com