Automobile air conditioner compressor piston hemisphere matching method

A technology for automotive air conditioners and compressors, which is applied in special data processing applications, instruments, and electrical digital data processing, etc. It can solve the problems of large piston assembly errors and low precision of piston hemisphere selection, so as to improve accuracy, reduce errors, and reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

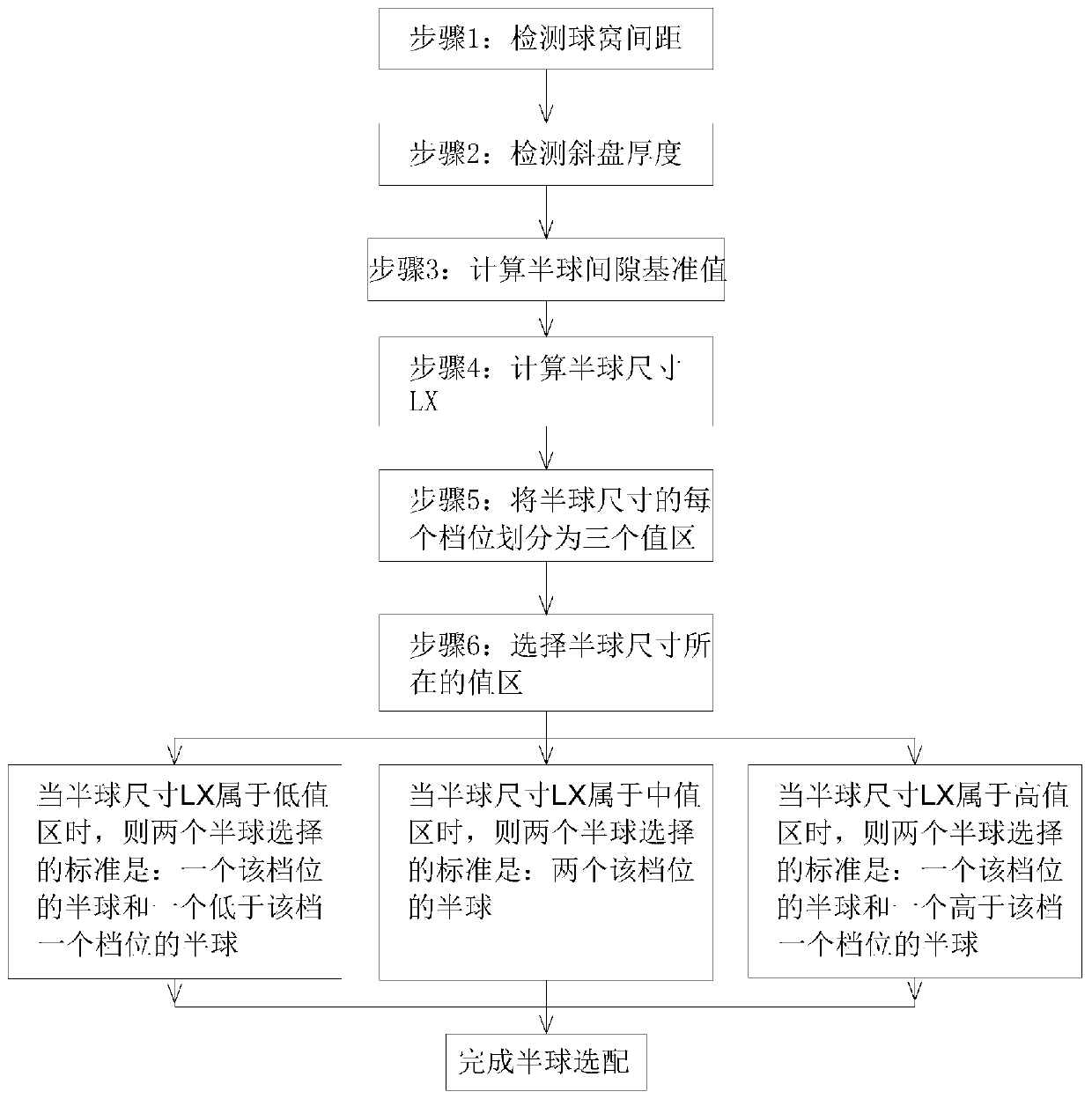

[0027] A method for matching piston hemispheres of an automobile air-conditioning compressor, the method comprising the following steps:

[0028] Step S1: Detect the distance between the two ball sockets of the piston base, obtain the ball socket distance value as L1=28.9907mm.

[0029] Step S2: Detect the thickness of the swash plate, and record the thickness value as L2=13.1277mm;

[0030] Step S3: Calculate the reference value L3 of the hemispherical gap according to the set numerical range of the hemispherical gap, L3=(upper limit of the hemispherical gap+lower limit of the hemispherical gap) / 2=(0.048+0.016) / 2=0.032mm;

[0031] Step S4: Calculate the hemispherical size LX=(L1-L2-L3) / 2=7.9155mm by the numerical value obtained in steps S1-S3;

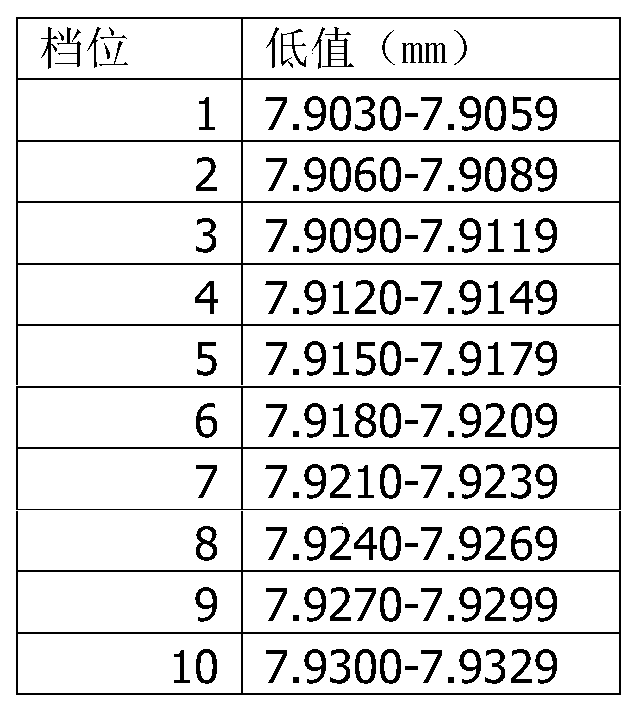

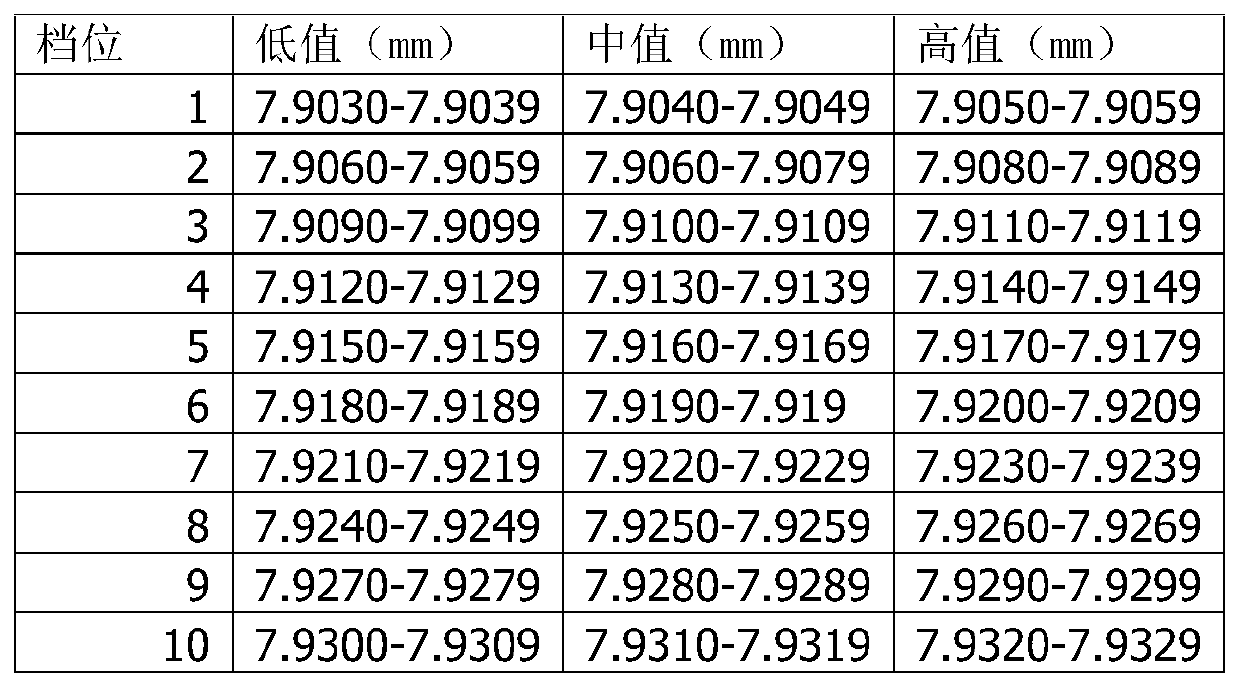

[0032] Step S5: Divide each gear of the hemisphere size into three value areas, which are divided into low value area, middle value area and high value area;

[0033] Step S6: Determine the value range of the hemisphere size LX obta...

Embodiment 2

[0038] A method for matching piston hemispheres of an automobile air-conditioning compressor, the method comprising the following steps:

[0039] Step S1: Detect the distance between the two ball sockets of the piston base, and obtain the ball socket distance value as L1=29.0411mm;

[0040] Step S2: Detect the thickness of the swash plate, and record the thickness value as L2=13.1701mm;

[0041] Step S3: Calculate the reference value L3 of the hemispherical gap according to the set numerical interval of the hemispherical gap, L3=(upper limit of the hemispherical gap+lower limit of the hemispherical gap) / 2=0.032mm;

[0042]Step S4: Calculate the hemispherical size LX=(L1-L2-L3) / 2=7.9195mm by the numerical value obtained in steps S1-S3;

[0043] Step S5: Divide each gear of the hemisphere size into three value areas, which are divided into low value area, middle value area and high value area;

[0044] Step S6: Determine the value range of the hemisphere size LX obtained in st...

Embodiment 3

[0049] A method for matching piston hemispheres of an automobile air-conditioning compressor, the method comprising the following steps:

[0050] Step S1: Detect the distance between the two ball sockets of the piston base, obtain the ball socket distance value as L1=29.0395mm.

[0051] Step S2: Detect the thickness of the swash plate, and record the thickness value as L2=13.1845mm;

[0052] Step S3: Calculate the reference value L3 of the hemispherical gap according to the set numerical interval of the hemispherical gap, L3=(upper limit of the hemispherical gap+lower limit of the hemispherical gap) / 2=0.032mm;

[0053] Step S4: Calculate the hemispherical size LX=(L1-L2-L3) / 2=7.9115mm by the numerical value obtained in steps S1-S3;

[0054] Step S5: Divide each gear of the hemisphere size into three value areas, which are divided into low value area, middle value area and high value area;

[0055] Step S6: Determine the value range of the hemisphere size LX obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com