Bearing outer sleeve ring detection system

A bearing jacket and detection system technology, applied in sorting and other directions, can solve the problems of low detection efficiency of the detection system, uncontrollable transmission rhythm, and workpiece waiting, etc., to achieve the effect of convenient rhythm control, consistent work rhythm, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, and those of ordinary skill in the art can make structural, method, or functional transformations according to these embodiments. All are included in the protection scope of the present invention.

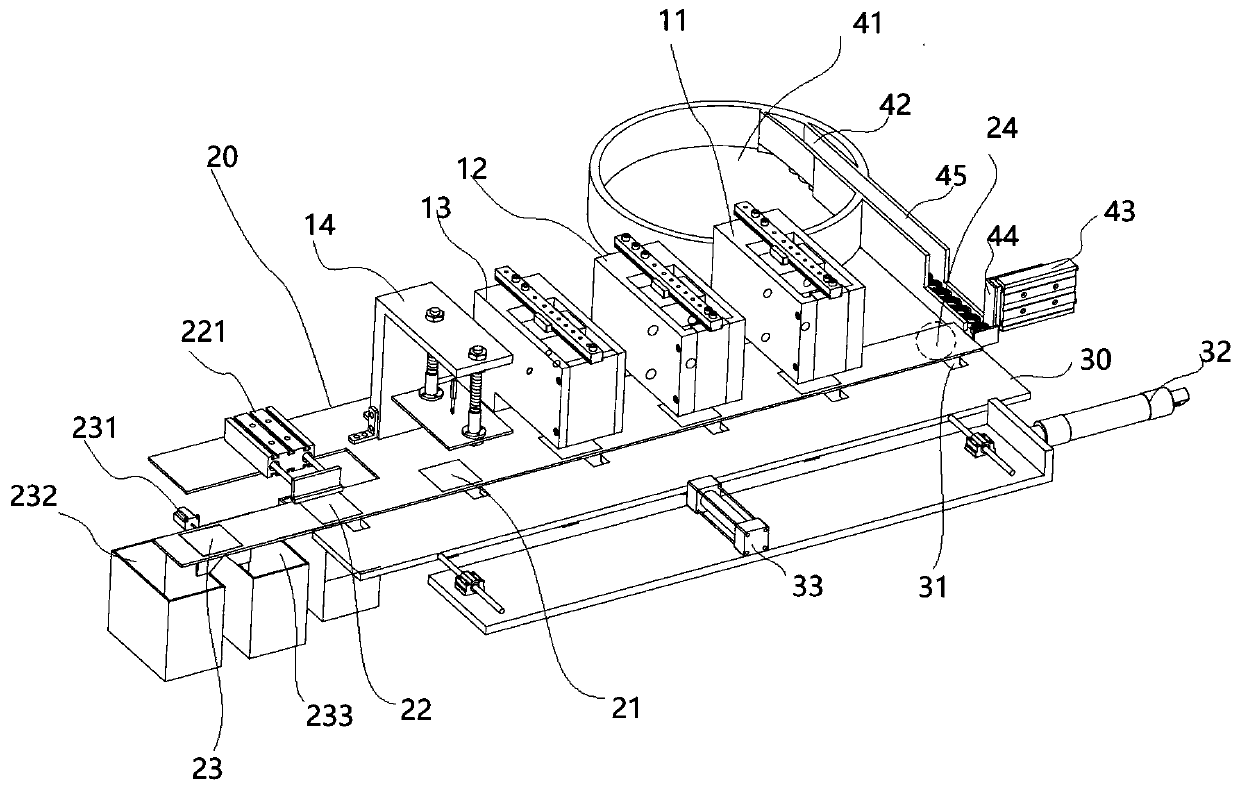

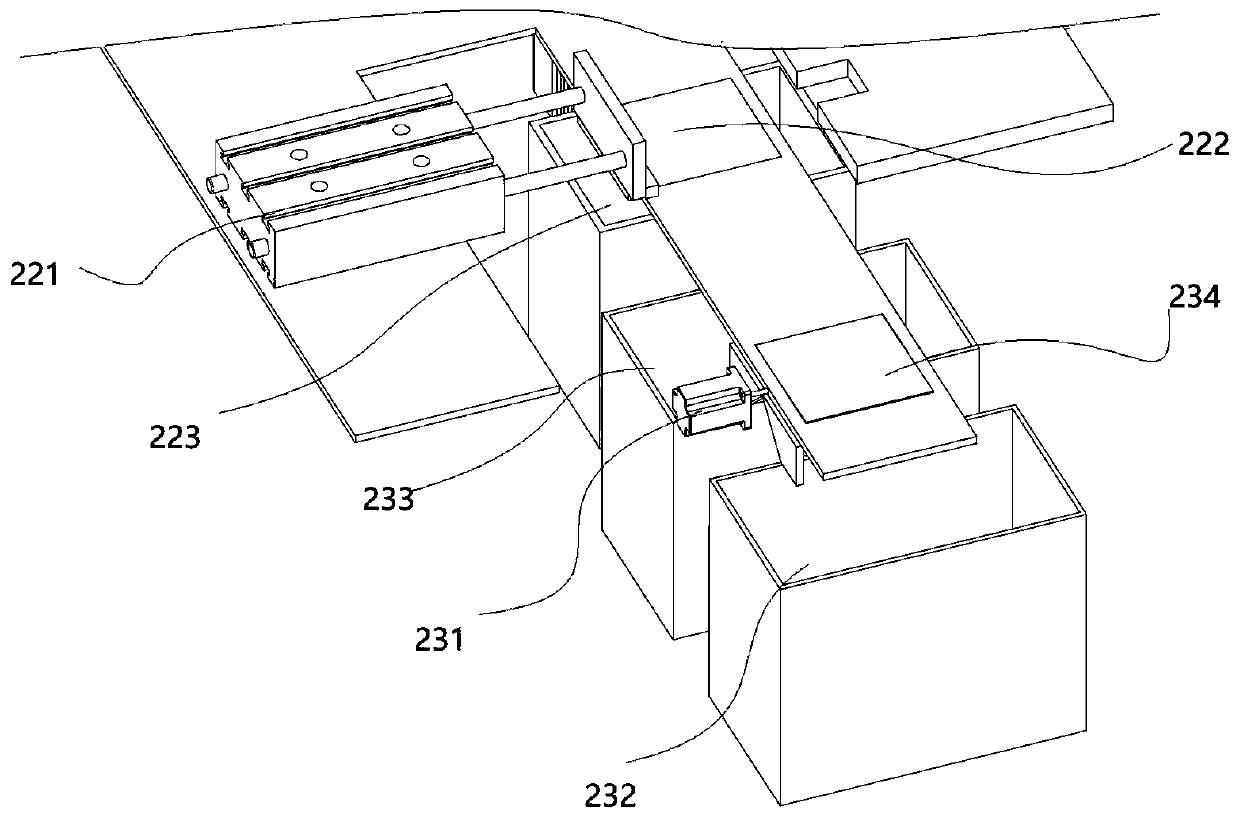

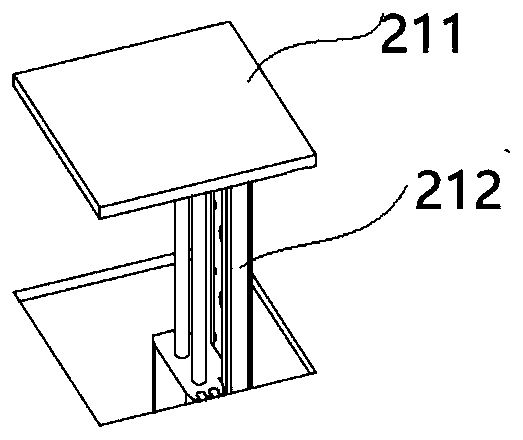

[0024] See figure 1 , figure 1 It is a three-dimensional schematic diagram of the bearing outer ring detection system according to the first embodiment of the present invention. As shown in the figure, the inspection system 100 includes a group of inspection devices, a long work station 20 , a mobile gripper 30 and a material bin 40 .

[0025] The detection device group usually includes a plurality of detection devices with different detection functions, such as figure 1 In the first embodiment shown, the detection device group includes four detection devices with different detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com