Derusting machine capable of improving derusting effect

A rust removal machine and chassis technology, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc., can solve the problems of rust removal work influence, muscle fatigue, and difficulty in maintaining uniform rust removal force, so as to reduce cleaning Time, improve the effect of rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

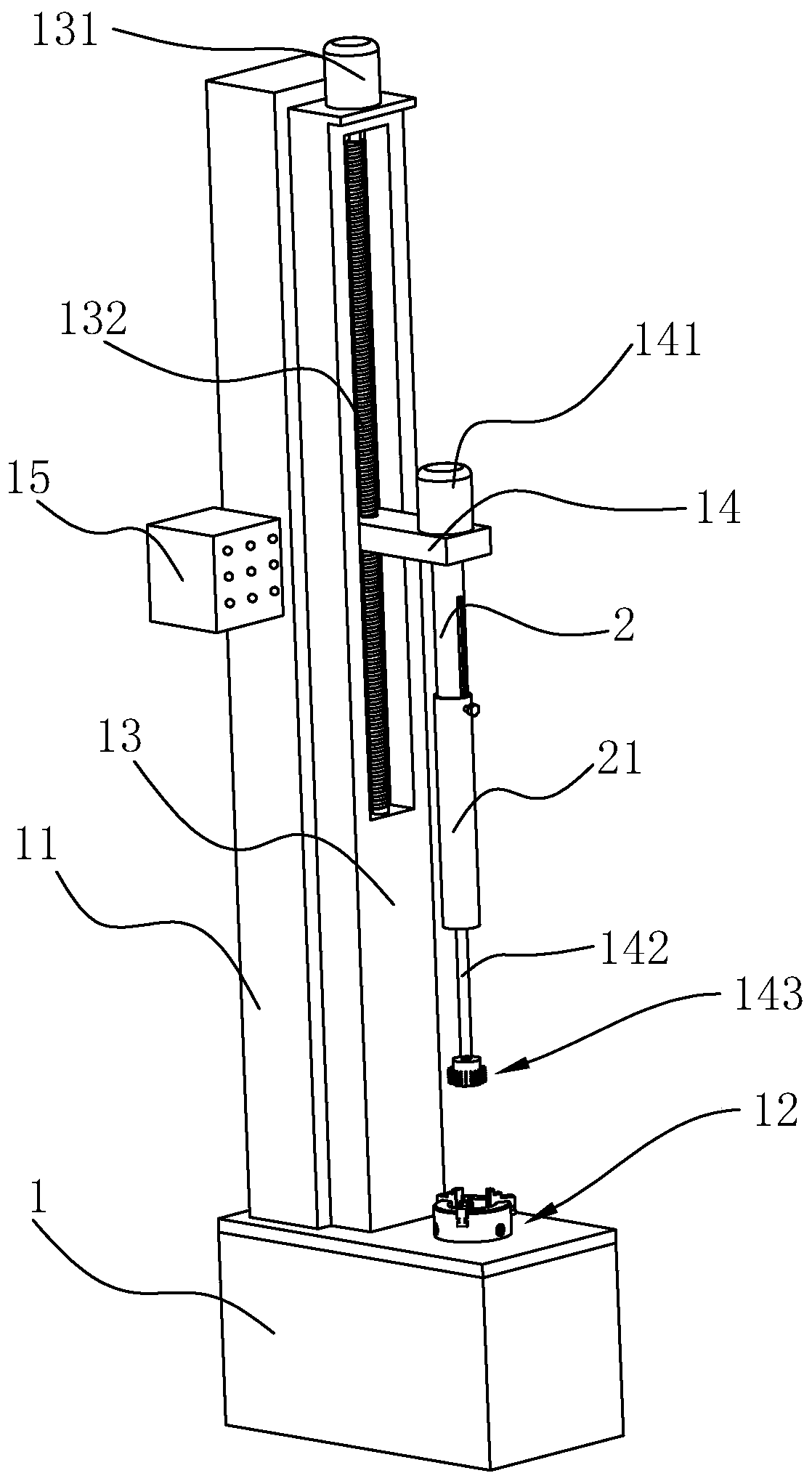

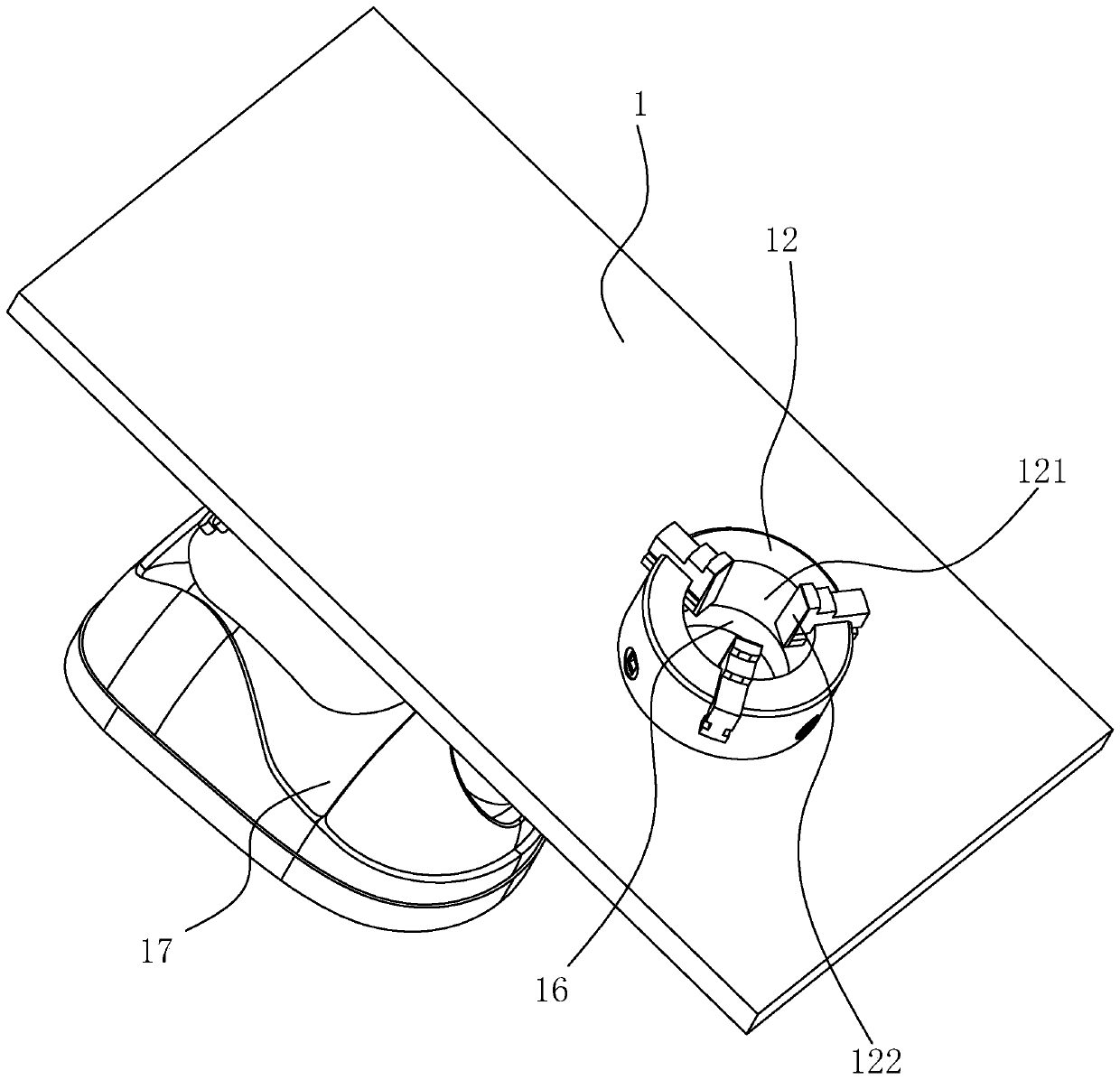

[0038] A kind of derusting machine that improves derusting effect, refer to figure 2 , which includes a support box 1 and a cabinet 11 welded and fixed on the top wall of the support box 1. The top wall of the support box 1 is also threaded with a clamping piece 12 for clamping the product pipe. The clamping piece 12 is preferably It is a three-jaw chuck, and a screw slide 13 is welded on the side wall of the cabinet 11 close to the direction of the clamping part 12. The length direction of the screw slide 13 is the vertical direction, and the top wall of the screw slide 13 can be moved by bolts. The first driving member 131 is disassembled and connected, and the first driving member 131 is preferably a servo motor. The drive shaft of the first driving member 131 runs through the top wall of the screw rod slide table 13, and is welded with an adjusting screw rod 132. The adjusting screw rod 132 is along the The length direction of the screw mandrel slide 13 is arranged, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com