Five-layer co-extruded high-strength transparent film special for vegetables and flowers and preparation method thereof

A high-strength, transparent technology, applied in the field of agricultural film, can solve the problems of poor transparency, softness and dustproof effect, can not meet the needs of modern agricultural development, affect the light and growth of crops, and achieve high mechanical strength and rub resistance , reduce labor input costs, and meet the effect of multi-stubble growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this embodiment, EVA is added to the layer and secondary outer layer.

[0066] The ratio of the inner layer of the greenhouse film: 20% LDPE (50kg) + 70% mLLDPE (175kg) + 10% inner layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly);

[0067] The ratio of the secondary inner layer of the greenhouse film: 20% LDPE (50kg) + 70% mLLDPE (175kg) + 10% secondary inner layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly);

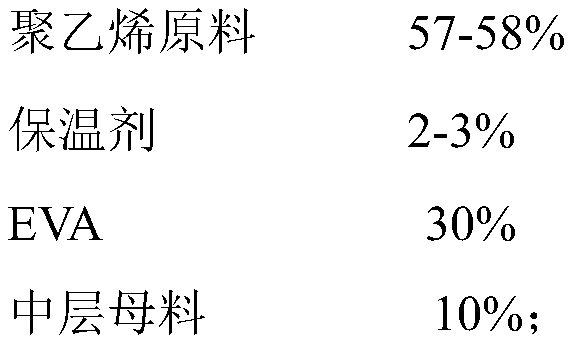

[0068] The ratio of the middle layer of the greenhouse film: 20% LDPE (50kg) + 40% EVA (high content VA, 100kg) + 30% LLDPE (75kg) + 10% middle layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly) ;

[0069] The ratio of the secondary outer layer of the greenhouse film: 20% LDPE (50kg) + 30% EVA (low content VA, 75kg) + 40% LLDPE (100kg) + 10% secondary outer layer masterbatch (25kg) (total 250kg pour into the mixture (Mixed evenly)

[0070] The ratio of the outer layer of the g...

Embodiment 2

[0082] In this example, all EVA was added to the middle layer, and the VA content was 14%.

[0083] The ratio of the inner layer of the greenhouse film: 20% LDPE (50kg) + 70% mLLDPE (175kg) + 10% inner layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly);

[0084] The ratio of the secondary inner layer of the greenhouse film: 20% LDPE (50kg) + 70% mLLDPE (175kg) + 10% secondary inner layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly);

[0085] The ratio of the middle layer of the greenhouse film: 20% LDPE (50kg) + 70% EVA (high content VA, 175kg) + 10% middle layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly);

[0086] The ratio of the secondary outer layer of the greenhouse film: 20%LDPE(50kg)+40%LLDPE(100kg)+30%mLLDPE(75kg)+10% secondary outer layer masterbatch (25kg) (total 250kg is poured into the mixer and mixed evenly) ;

[0087] The ratio of the outer layer of the greenhouse film: 20% LDPE (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com