Treatment method of ADN production wastewater

A technology for the production of wastewater and treatment methods, applied in the field of nanomaterials and nanomaterials, can solve the problems of slow microbial degradation rate, high toxicity inhibition, secondary pollution of iron sludge, etc., and achieve the elimination of safety impact, convenient operation and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment 1: process method of the present invention handles ADN production waste water

[0022] First, add ADN production wastewater into the photocatalytic reaction container, the total amount of wastewater is 200mL, and use a 600W ultraviolet lamp with a wavelength of 365nm to irradiate for 6h to obtain photochemically pretreated wastewater. The ADN content in the wastewater is 1.28mg / L;

[0023] Then, add dilute sulfuric acid solution to the wastewater after photochemical pretreatment to adjust the pH to 3, and then add 10% mass fraction of heterogeneous Fenton catalyst Fe to the photocatalytic reaction vessel. 2 o 3 , and then slowly and continuously drip the hydrogen peroxide with a mass-volume concentration of 30%. The ratio of the input amount of hydrogen peroxide in 1L of ADN production wastewater to the value of COD is 1:1, that is, add 179 mg of hydrogen peroxide to 1L of ADN production wastewater to complete the dropwise addition Continue to react...

specific Embodiment approach 2

[0027] Specific embodiment 2: Only use ultraviolet photocatalytic treatment of ADN production wastewater

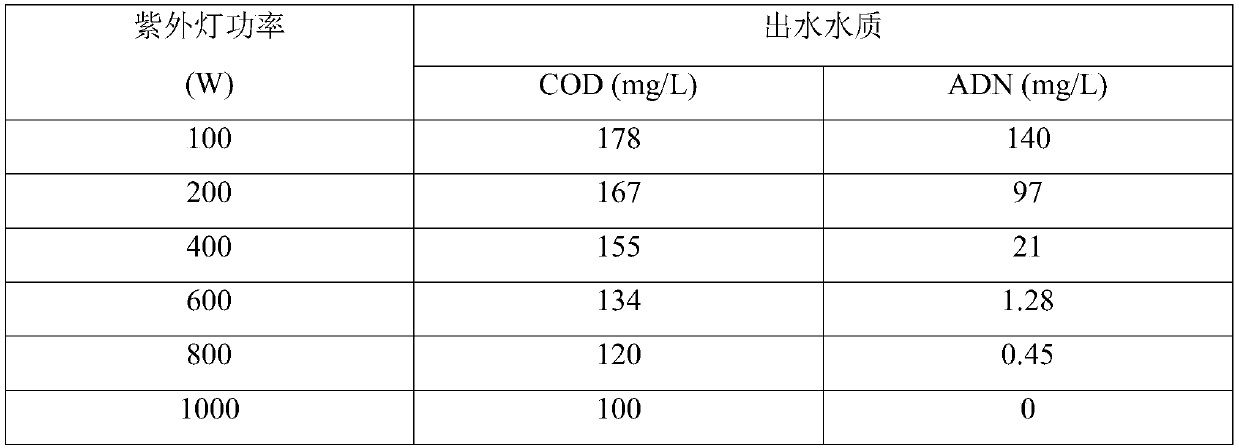

[0028] Add ADN production wastewater into the photocatalytic reaction container, the total amount of wastewater is 200mL, and there are 6 groups in total. Each group uses 100W, 200W, 400W, 600W, 800W, and 1000W ultraviolet lamps with a wavelength of 365nm to irradiate for 6 hours, and 6 groups are obtained. The water quality of the 6 groups of wastewater after pretreatment with different power ultraviolet lamps is as follows:

[0029]

[0030] It can be seen from the above table that only using ultraviolet photochemical method can only significantly reduce the concentration of ADN, but the degradation effect on organic pollutants in wastewater is poor.

specific Embodiment approach 3

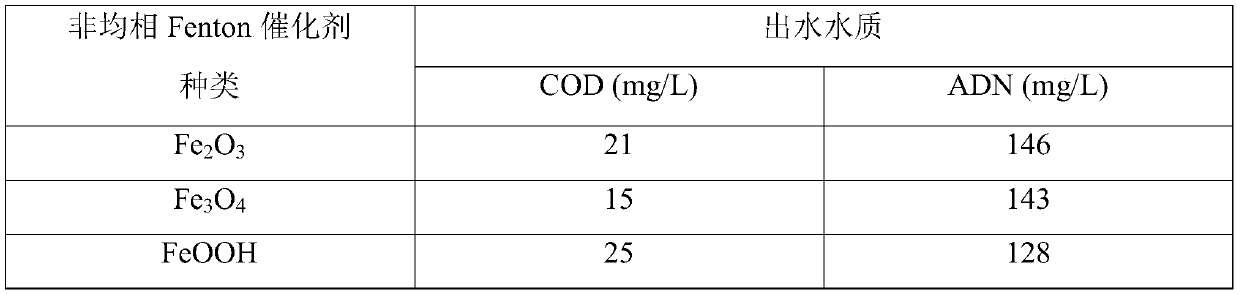

[0031] Specific embodiment 3: only using heterogeneous Fenton catalytic treatment of ADN production wastewater

[0032] Add ADN production wastewater into the photocatalytic reaction container, the total amount of wastewater is 200mL, a total of 3 groups, each group adjusts the pH value of the wastewater to 3, and each group adds 10% heterogeneous Fenton catalyst Fe 2 o 3 , Fe 3 o 4 and FeOOH, and then each group slowly and continuously drips hydrogen peroxide with a mass-volume concentration of 30%, that is, the ratio of hydrogen peroxide input to COD in 1L of ADN production wastewater is 1:1, that is, 179mg is added to 1L of ADN production wastewater After the hydrogen peroxide was added dropwise, the reaction was continued for 24 hours, and three groups of wastewater treated with different types of heterogeneous Fenton catalysts were obtained respectively. The water quality is as follows:

[0033]

[0034] It can be seen from the above table that only using the hetero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com