Controllable release halloysite supported molybdate and benzotriazole composite corrosion inhibitor and preparation method thereof

A technology of benzotriazole and composite corrosion inhibitor, which is applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of weakening the protective effect of coatings and poor dispersion of corrosion inhibitors, and achieve good corrosion inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Na 2 MoO 4 2H 2 O (10.0 g) was dissolved in 100 ml of deionized water, and then 4 g of HNTs was added thereto to form a suspension, called A suspension.

[0030] (2) Dissolve BTA (2g) in 100ml alcohol, called B solution.

[0031] (3) Transfer the suspension A to a 100ml beaker, then place the beaker in a vacuum tank, and use a vacuum pump to evacuate to 1.325E3Pa, and maintain this pressure for 60min, then put the system back under normal pressure 60min is called the completion of a loading process.

[0032] (4) Repeat the above cycle process, and redisperse the samples after two loadings in solution B to complete the third loading.

[0033] (5) Centrifuge and wash the sample loaded three times, then redisperse it into 0.08mol / L copper sulfate solution and stir for 1min, finally centrifuge, wash, dry at 60°C for 24h, and then grind to obtain HNTs Composite corrosion inhibitor material loaded with molybdate and benzotriazole.

Embodiment 2

[0035] (1) Na 2 MoO 4 2H 2 O (5.0 g) was dissolved in 100 ml of deionized water, and then 2 g of HNTs was added thereto to form a suspension, called A suspension.

[0036] (2) Dissolve BTA (1g) in 100ml of alcohol, called B solution.

[0037] (3) Transfer the suspension A to a 100ml beaker, then place the beaker in a vacuum tank, and use a vacuum pump to evacuate to 1.325E3Pa, and maintain this pressure for 30min, then put the system back under normal pressure 90min is called the completion of a loading process.

[0038] (4) Repeat the above cycle process, and redisperse the samples after two loadings in solution B to complete the third loading.

[0039] (5) Centrifuge and wash the sample after 6 times of loading, redisperse it into 0.01mol / L copper sulfate solution and stir for 10min, finally centrifuge, wash, dry at 90°C for 24h, and then grind to obtain HNTs Composite corrosion inhibitor material loaded with molybdate and benzotriazole.

Embodiment 3

[0041] 1) Na 2 MoO 4 2H 2 O (15.0 g) was dissolved in 100 ml of deionized water, and then 8 g of HNTs was added thereto to form a suspension, called A suspension.

[0042] (2) Dissolve BTA (4g) in 100ml alcohol, called B solution.

[0043] (3) Transfer suspension A to a 100ml beaker, then place the beaker in a vacuum tank, and use a vacuum pump to evacuate to 1.325E3Pa, and maintain this pressure for 120min, then put the system back under normal pressure 120min is called completing a loading process.

[0044] (4) Repeat the above cycle process, and redisperse the samples after two loadings in solution B to complete the third loading.

[0045] (5) Centrifuge and wash the sample after 5 times of loading, redisperse it into 0.20mol / L copper sulfate solution and stir for 5min, finally centrifuge, wash, dry at 40°C for 24h, and then grind to obtain HNTs Composite corrosion inhibitor material loaded with molybdate and benzotriazole.

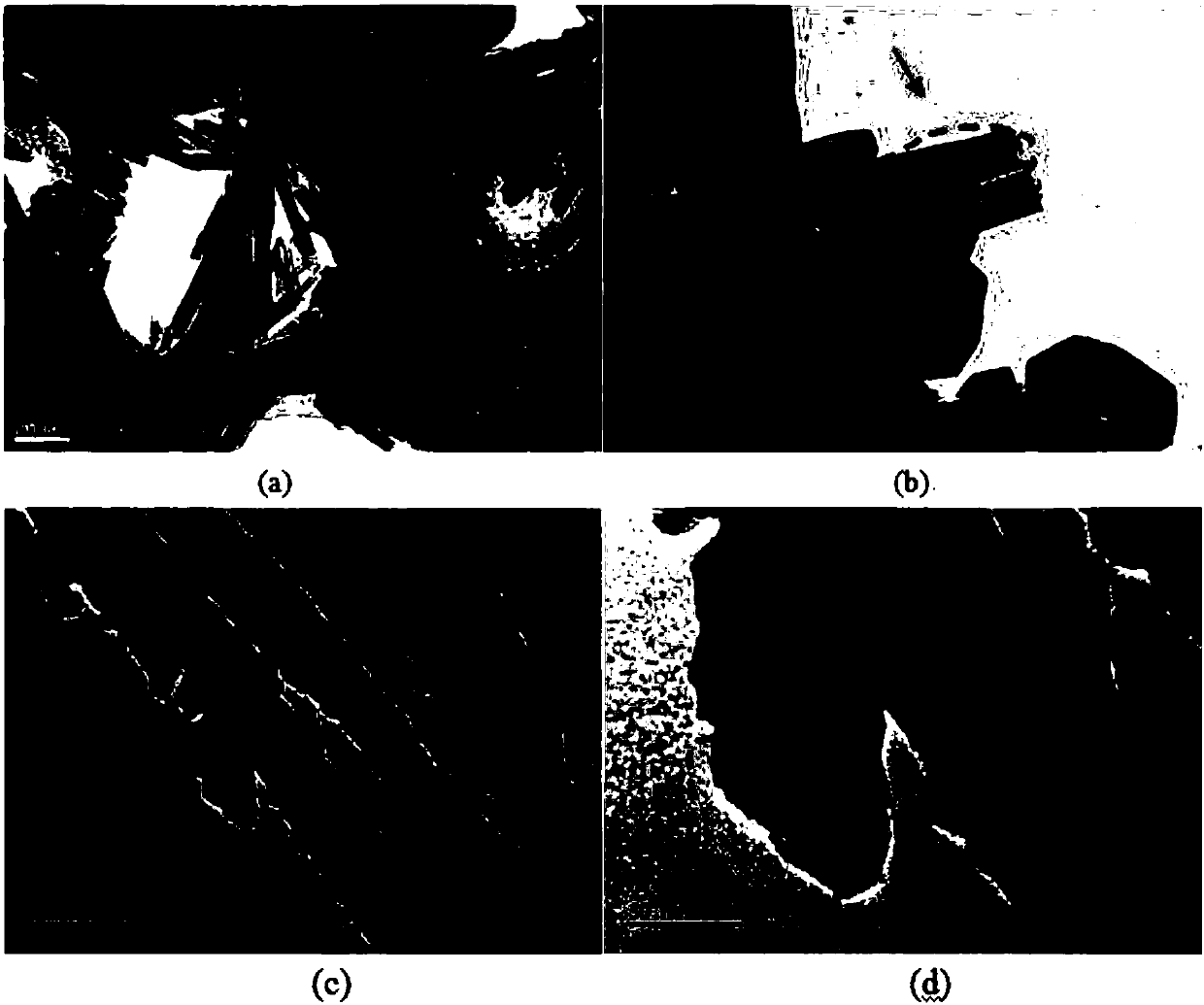

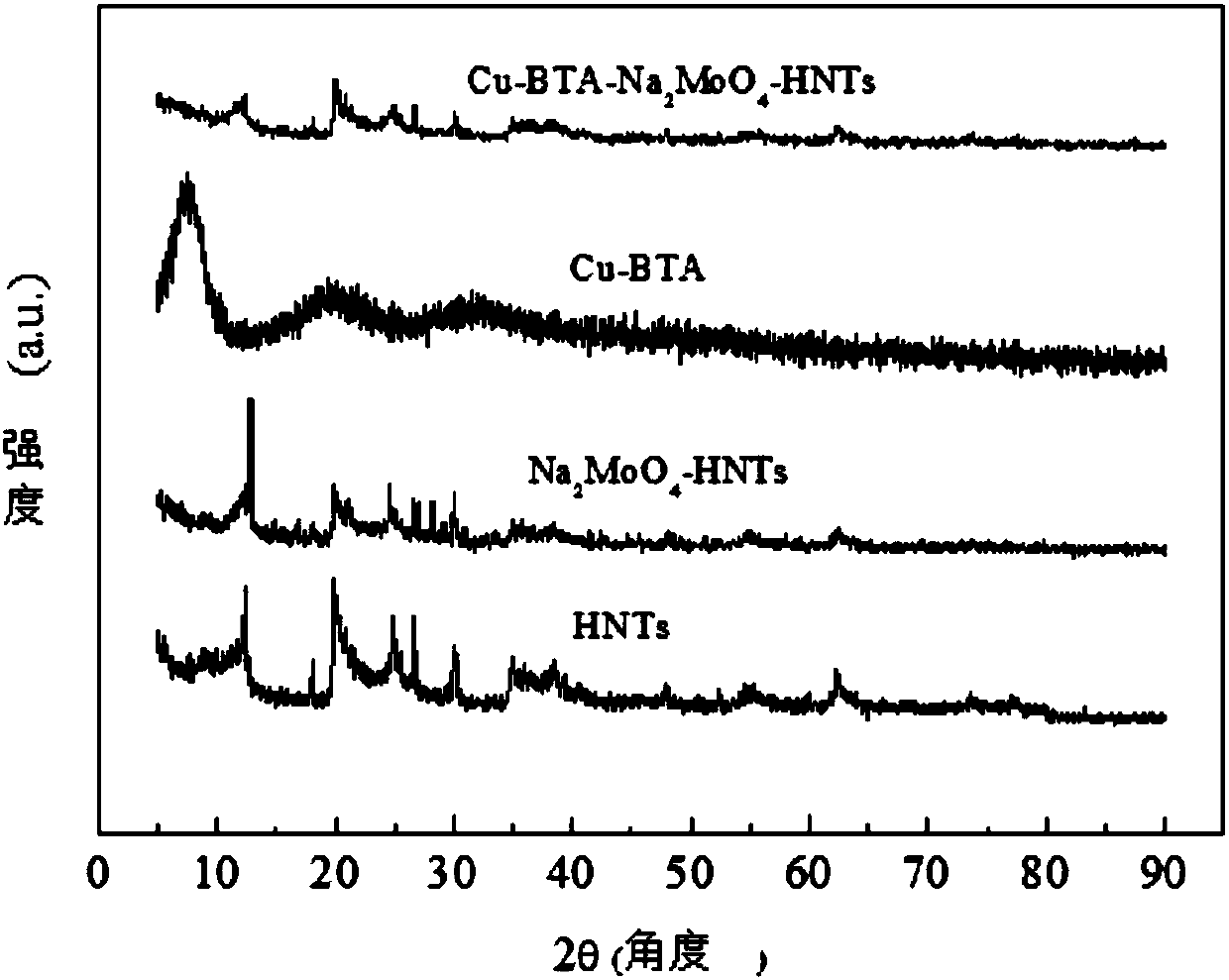

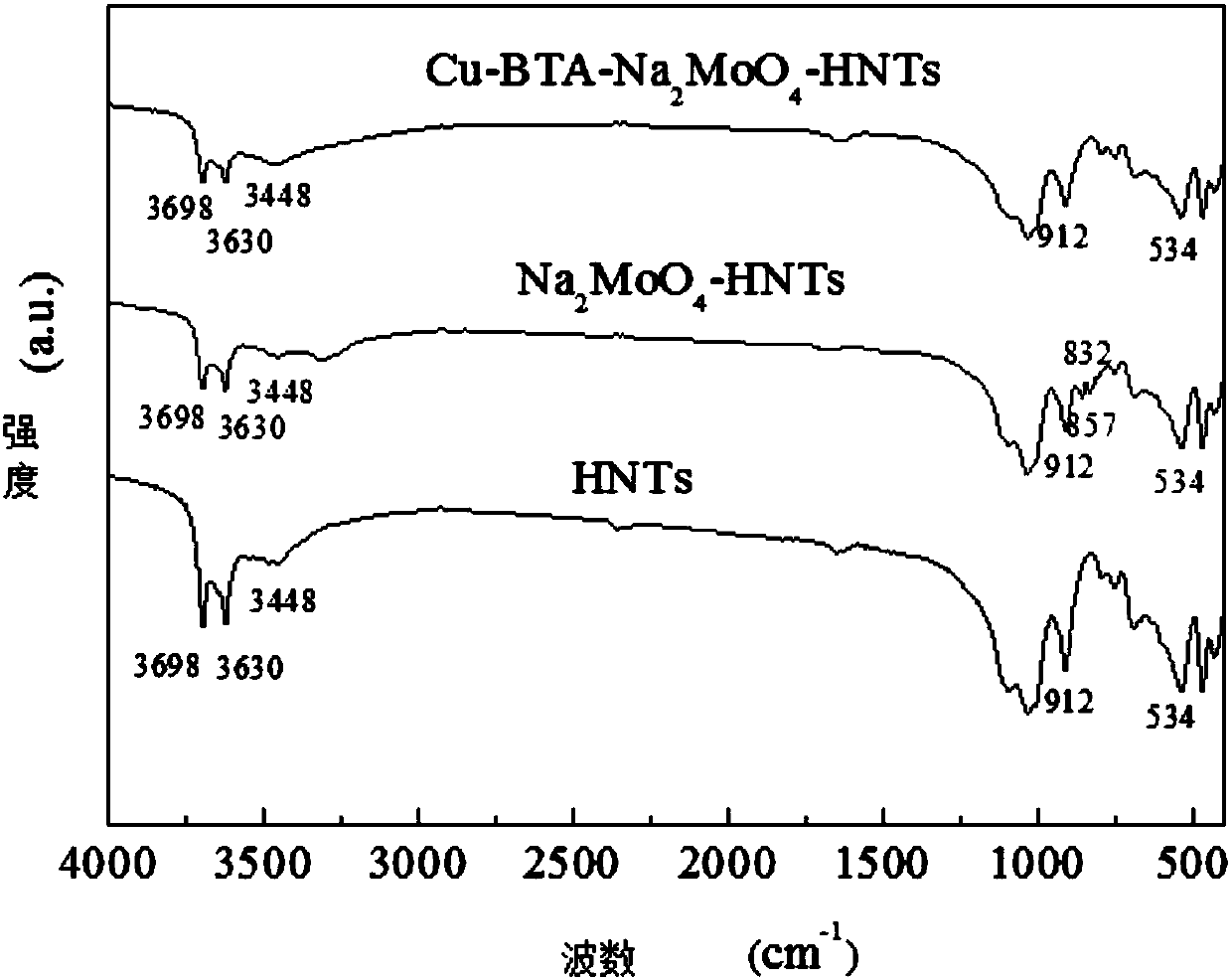

[0046] figure 1 are HNTs, Na 2 MoO 4 -H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com