A film covering equipment after the initial setting of concrete and before the final setting

A concrete and final setting technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of lack of humidity coverage, loss of moisture protection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

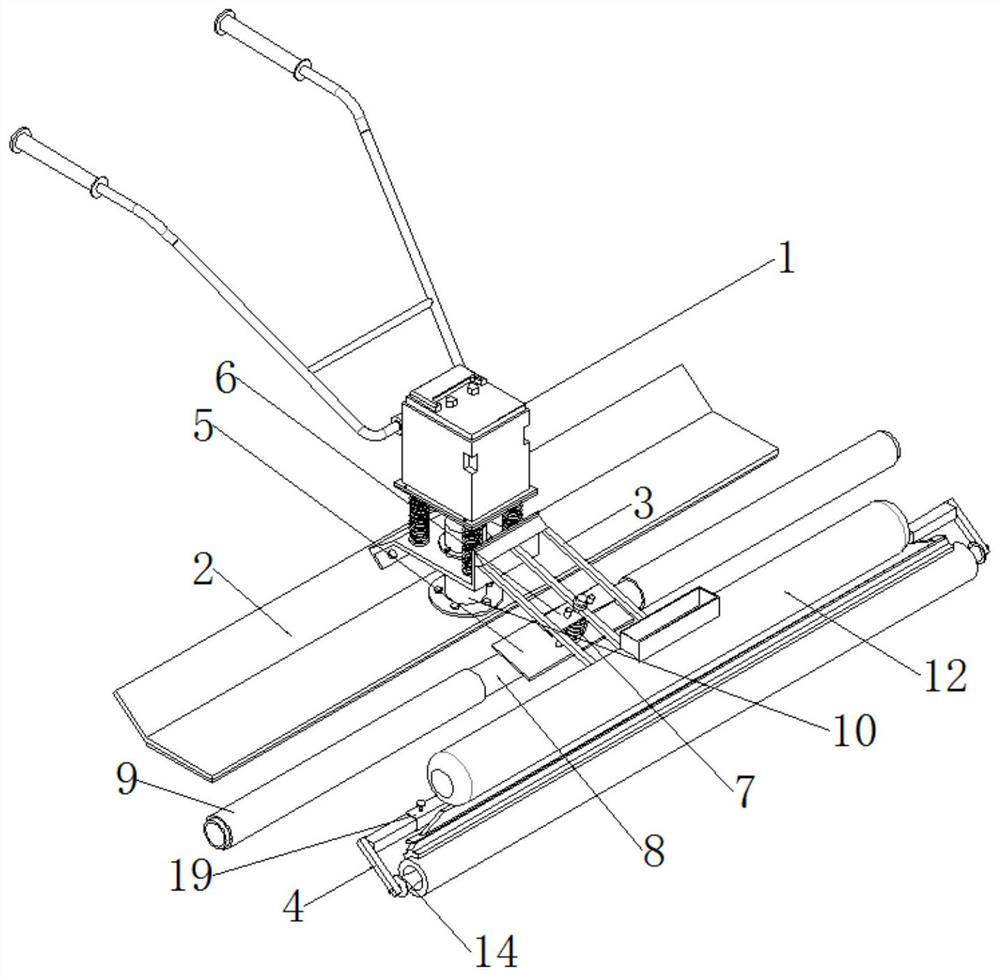

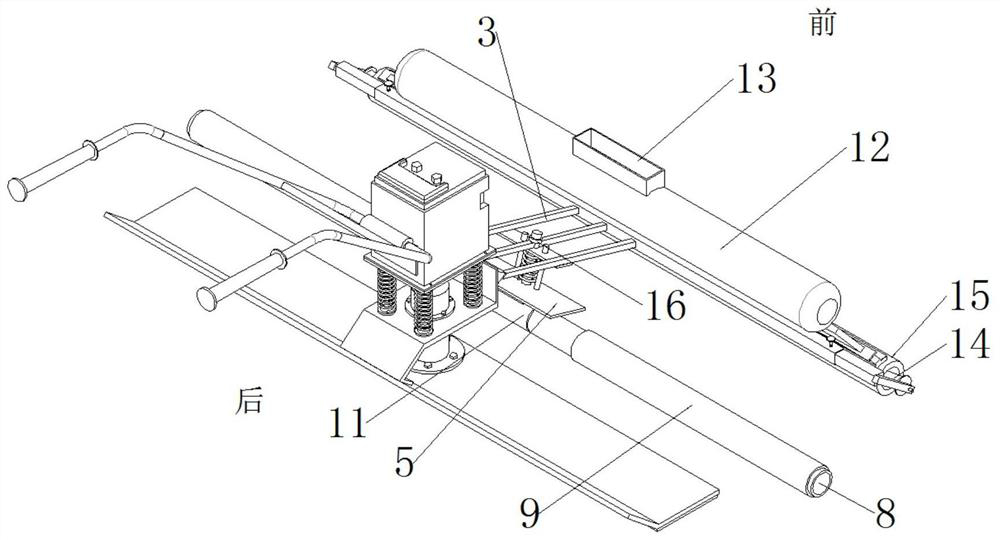

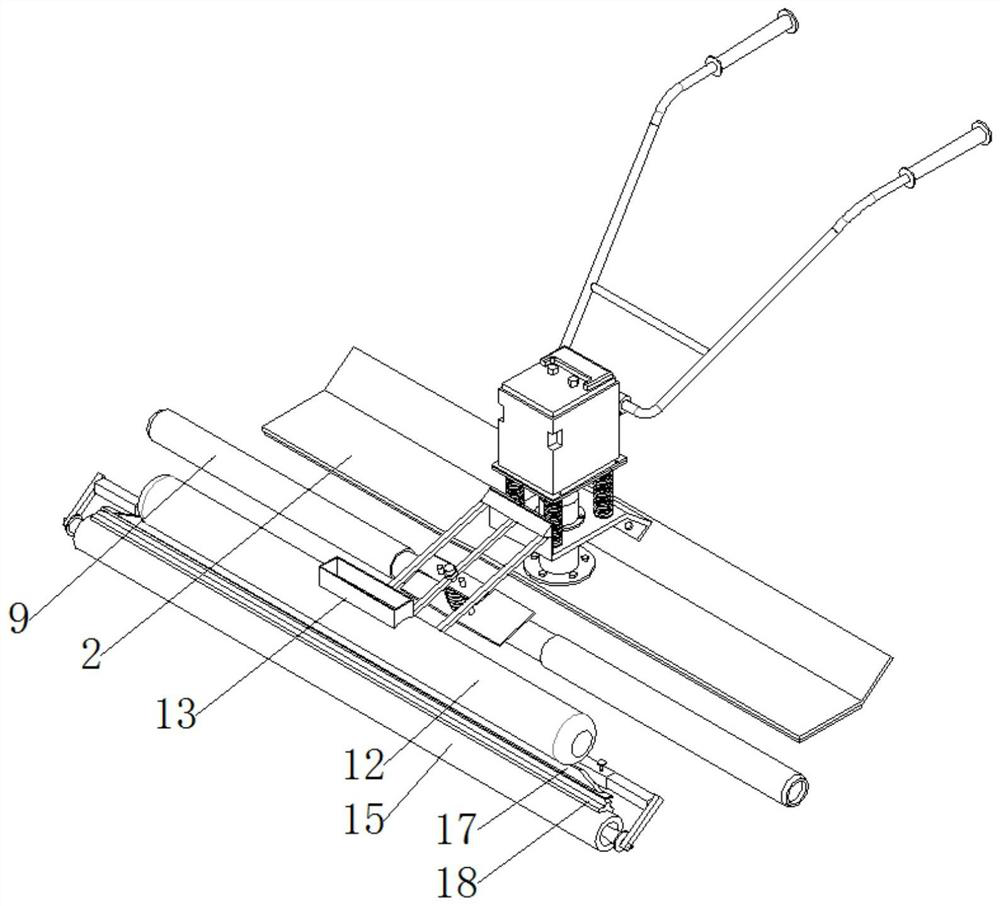

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031]The invention provides a film coating equipment after the initial setting of concrete and before the final setting, which includes a high-frequency vibration seat 1, a pressure film plate 2, a front support frame 3, a clamping seat 4, a bottom welding plate 5, a top welding plate 6, and vibration reduction Device 7, drum 8, rubber sleeve 9, high-frequency vibrator 10, bearing seat 11, drip bucket 12, liquid injection port 13, card post 14, film roller 15, guide sleeve 16, flow seat 17, test seat 18, Sleeve assembly 19 and bottom pad 20; the high-frequency vibrating seat 1 is composed of a top power supply and a high-frequency vibrator 10 at the bottom, and a thin plate-shaped lamination plate 2 is installed on the bottom surface of the high-frequency vibrator 10, and this The middle position of the pressure film plate 2 is bolted to the bottom mounting plate of the high-frequency vibrating seat 1; the front side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com