Prestress grouted rock bolt and installing and recycling method thereof

A prestressing and anchoring technology, which is applied in the installation of anchors, earthwork drilling, sheet pile walls, etc., can solve the problems of difficult recycling, inability to adapt to the purpose of support, and the need to improve the anchoring effect, so as to achieve large anchoring force, Good anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

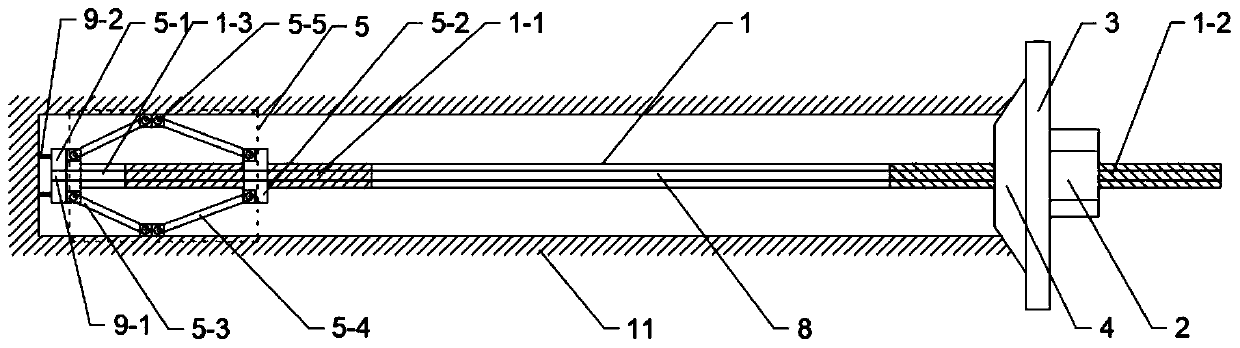

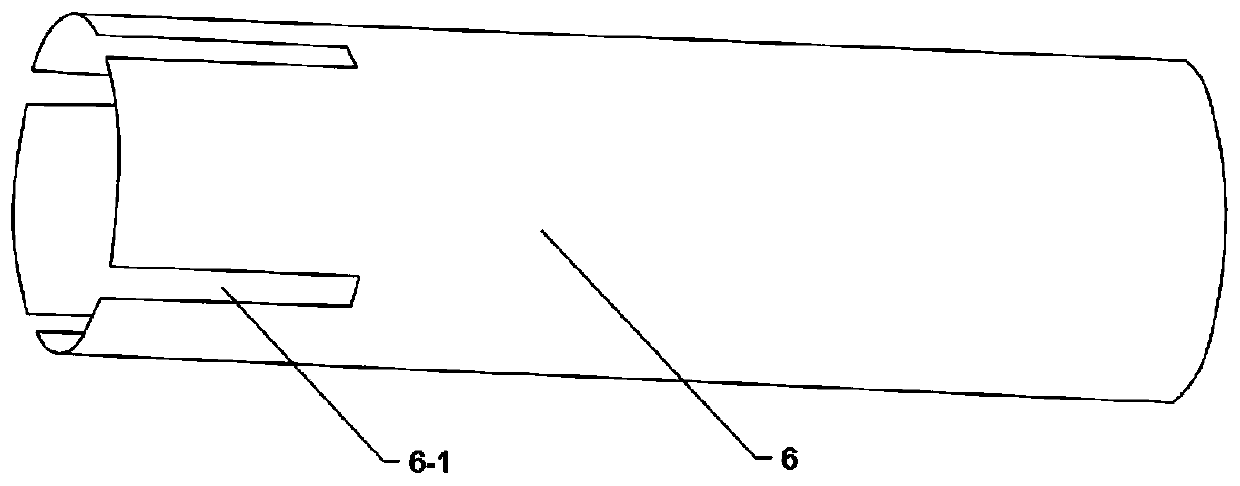

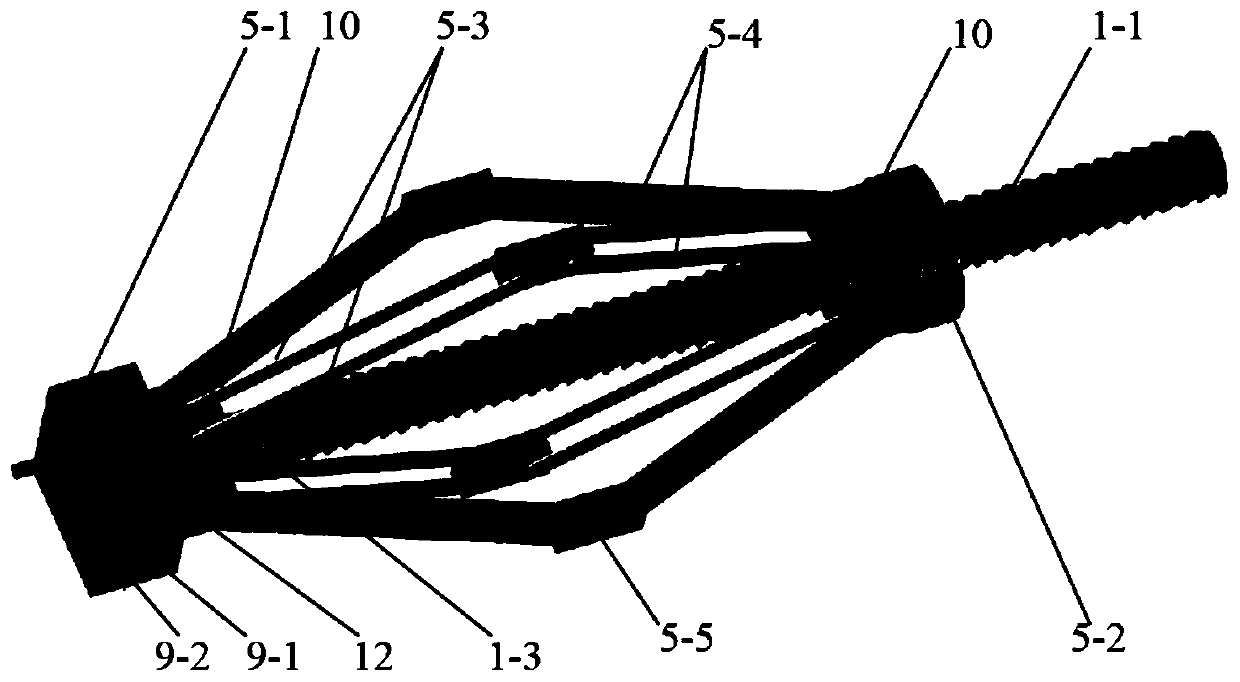

[0044] In this embodiment, the structural diagram of the prestressed grouting anchor is as follows figure 1 As shown, it includes a hollow screw 1 , a fixing nut 2 , a tray 3 , a grout stopper 4 , an anchor 5 and an installation sleeve 6 .

[0045] The hollow screw 1 includes a first threaded section 1-1, a second threaded section 1-2 and a non-threaded section 1-3, and an end is provided between the first threaded section 1-1 and the second threaded section 1-2. A blank segment with thread, the thread direction of the first thread segment 1-1 and the second thread segment 1-2 are opposite, specifically, the first thread segment is a left-handed thread segment, the second thread segment is a right-handed thread segment, and the second thread segment is a right-handed thread segment. One end of a threaded section is connected to the unthreaded section 1-3, and the end of the unthreaded section is provided with a clip joint 7. Such as Figure 5 As shown, the snap joint 7 is co...

Embodiment 2

[0050] In this embodiment, the structural diagram of the prestressed grouting anchor is similar to figure 1 , including a hollow screw 1, a fixing nut 2, a tray 3, a grout stopper 4, an anchor 5 and an installation sleeve 6,

[0051] The hollow screw 1 includes a first threaded section 1-1, a second threaded section 1-2 and a non-threaded section 1-3, and an end is provided between the first threaded section 1-1 and the second threaded section 1-2. A blank segment with thread, the thread direction of the first thread segment 1-1 and the second thread segment 1-2 are opposite, specifically, the first thread segment is a left-handed thread segment, the second thread segment is a right-handed thread segment, and the second thread segment is a right-handed thread segment. One end of a threaded section is connected to the unthreaded section 1-3, and the end of the unthreaded section is provided with a clip joint 7. Such as Figure 5 As shown, the snap joint 7 is composed of a sna...

Embodiment 3

[0056] In this embodiment, the installation and recovery method of the prestressed grouting anchor described in embodiment 1 or 2 is provided, and the steps are as follows:

[0057] ① Drill the borehole 11 in the surrounding rock, and select the prestressed grouting bolt with the appropriate size according to the size of the borehole;

[0058] ② Put the installation sleeve on the hollow screw with the anchor installed, adjust the angle between the upper support and the lower support so that the top of the anchor protrudes from the limit groove of the installation sleeve and put it in After drilling, the plug does not touch the wall of the drilled hole, such as Figure 7 As shown, then put the installation sleeve into the drill hole so that the support feet on the base of the anchor and the installation sleeve are against the bottom of the drill hole so that the axis of the hollow screw coincides with the axis of the drill hole, fix the installation sleeve, and turn clockwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com