Engine auxiliary starter

An engine and starter technology, applied in the direction of engine starting, engine components, machines/engines, etc., can solve problems such as short service life, achieve the effect of high combination success rate, ensure stable start, and eliminate stagnation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

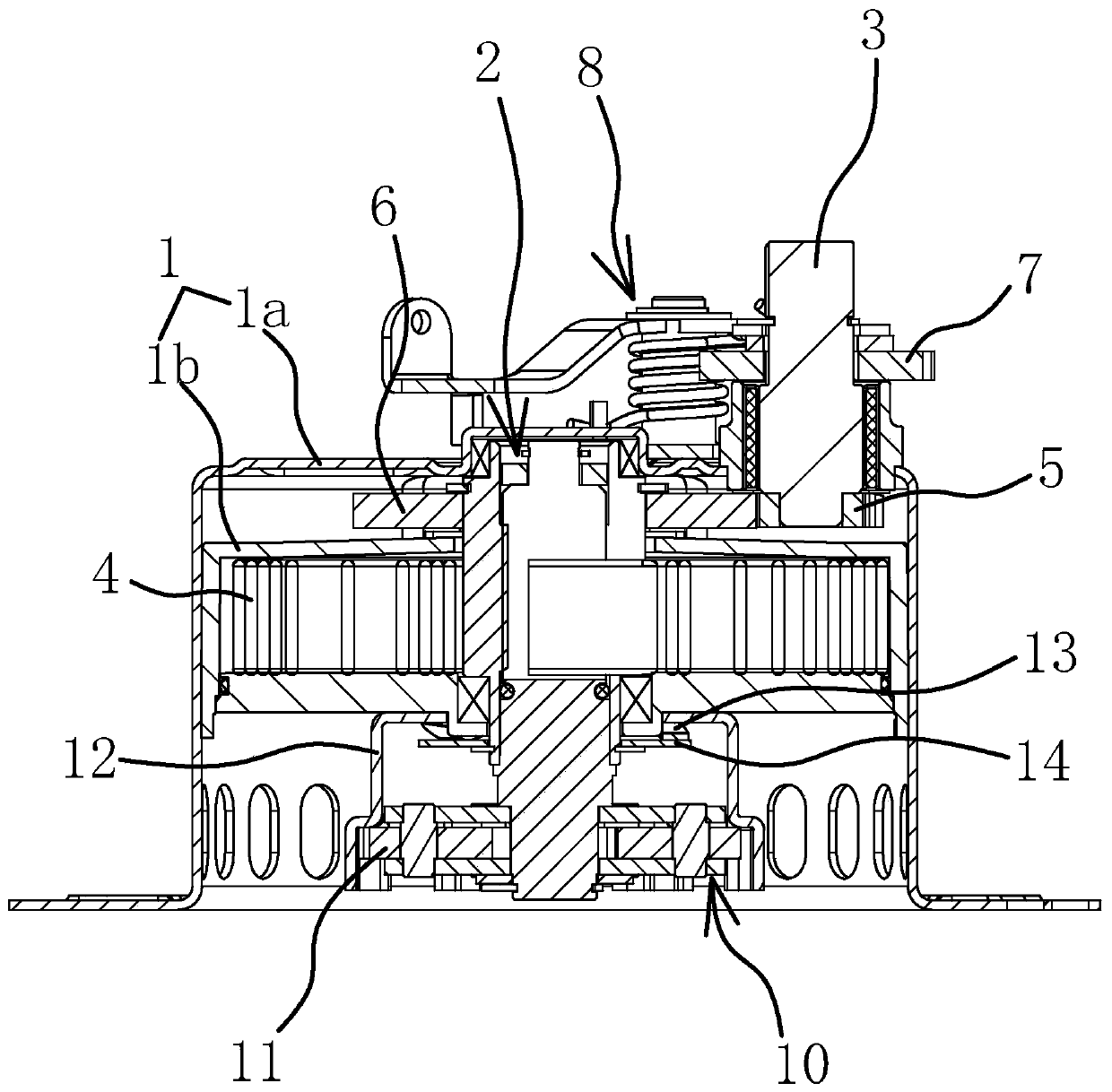

[0045] Such as figure 1 As shown, the auxiliary starter of the engine includes a body 1, a rotatable shaft 2 provided on the body 1 and capable of driving the shaft 2 to rotate, and a clutch mechanism connected to the shaft 2.

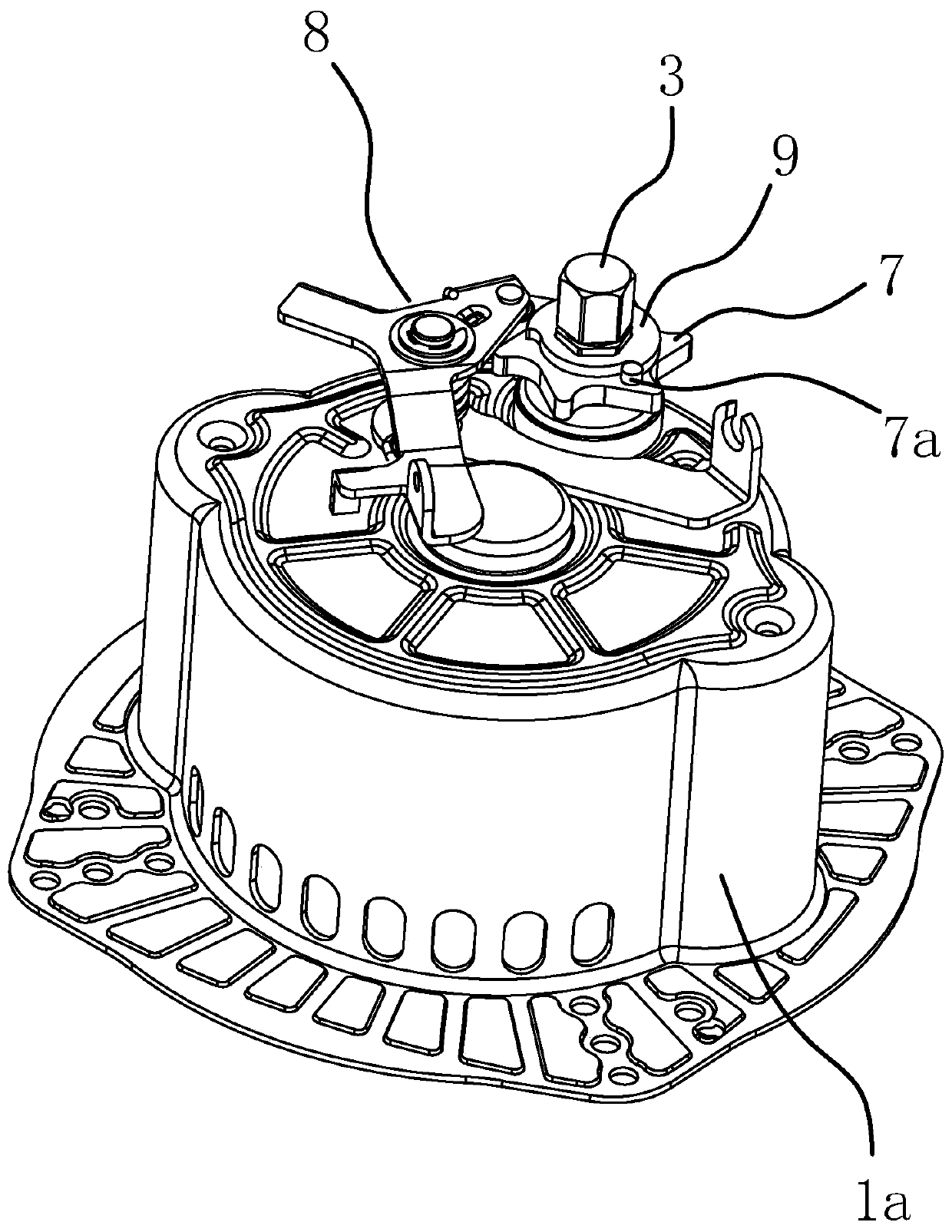

[0046] Such as figure 1 with figure 2 As shown, the body 1 includes a casing 1a with one end open and the other end closed, and a spring box 1b fixed in the casing 1a. The spring box 1b is provided with a spiral spring 4, and one end of the outer edge of the spiral spring 4 is fixed to the spring. On the box 1b, the rotating shaft 2 passes through the center of the scroll spring 4, and one end of the inner edge of the scroll spring 4 is connected to the rotating shaft 2. One end of the starting shaft 3 is located in the housing 1 a and is connected with a driving gear 5, one end of the rotating shaft 2 extends out of the spring box 1 b and is connected with a driven gear 6, and the driving gear 5 meshes with the driven gear 6. A ratchet 7 is sleeved on o...

Embodiment 2

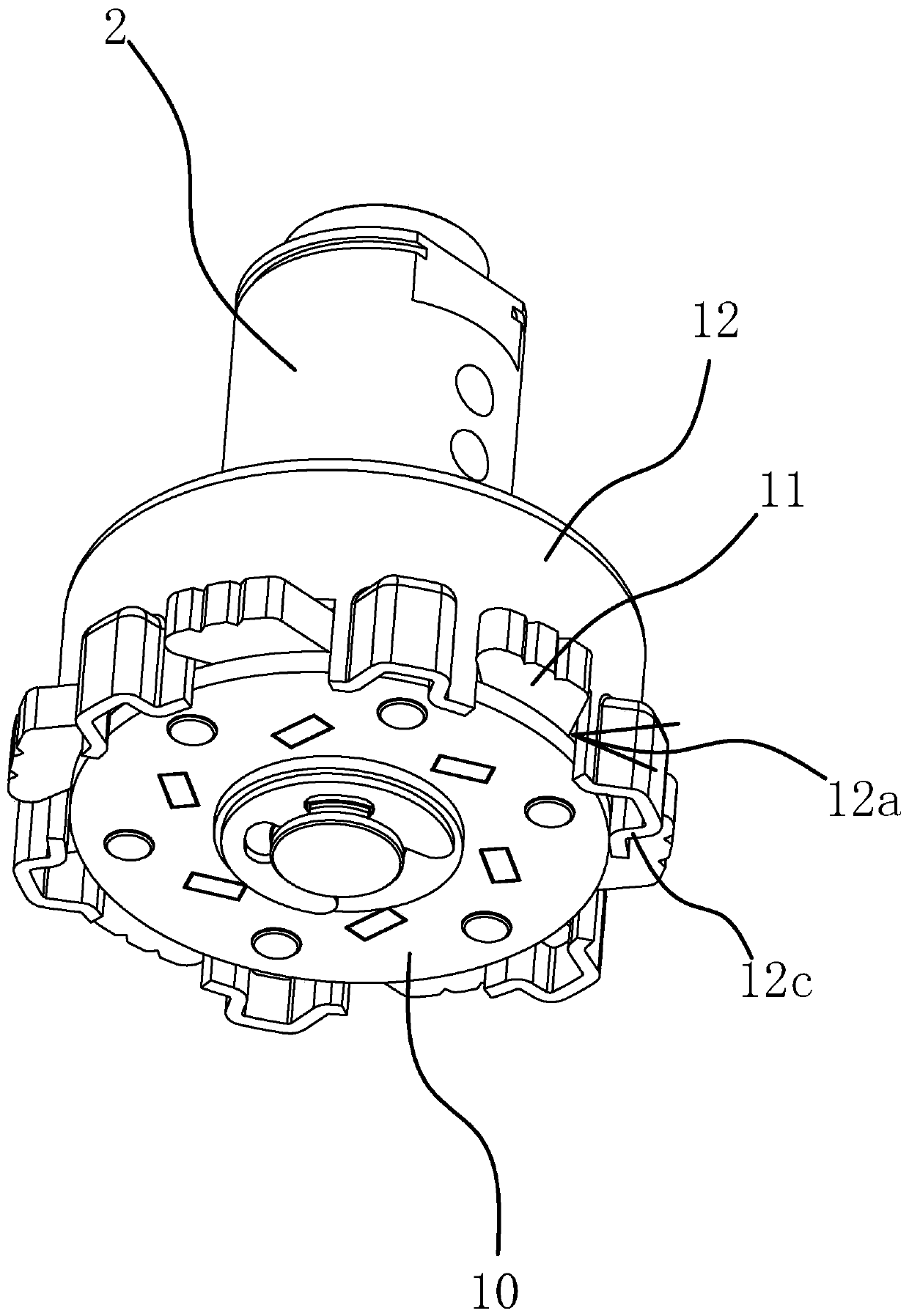

[0056] The structure and principle of this embodiment are basically the same as those of the first embodiment, but the difference lies in: Figure 8-10 As shown, in this embodiment, the number of activation claws 11 is three, and the outer edge of the claw base 10 is provided with a number of accommodating grooves 10a3, each activation claw 11 is located in each accommodating groove 10a3, and the limiting portion 10a1 is the accommodating groove The inside of 10a3 corresponds to the side wall in the center direction of the claw base 10. Specifically, the claw seat 10 includes an upper seat body 10a and a lower seat body 10b. The receiving groove 10a3 is opened between the lower end surface and the outer peripheral surface of the upper seat body 10a. The lower seat body 10b limits the activation pawls 11 in the receiving groove 10a3 to prevent Prolapse. The limiting portion 10a1 is an outer convex arc surface, and the inner end of the activation pawl 11 is provided with an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com