Arc pipe construction method for mechanical arcing

A kind of pipeline construction and arc technology, which is applied in the direction of mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. The overall beauty and coordination, the use of pipe fittings is reduced, and the maintenance is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

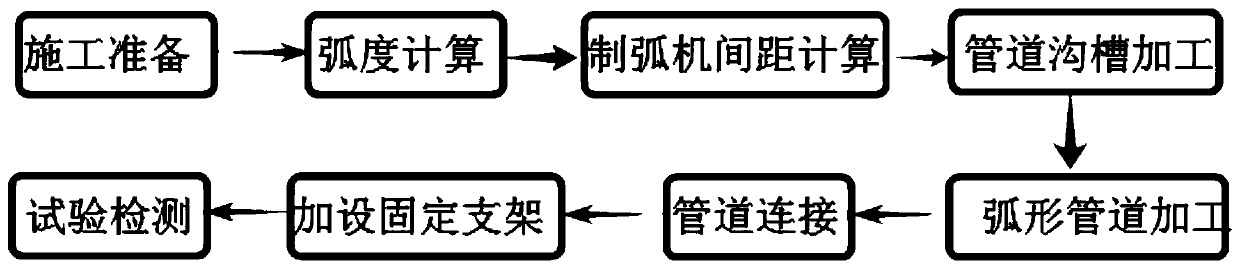

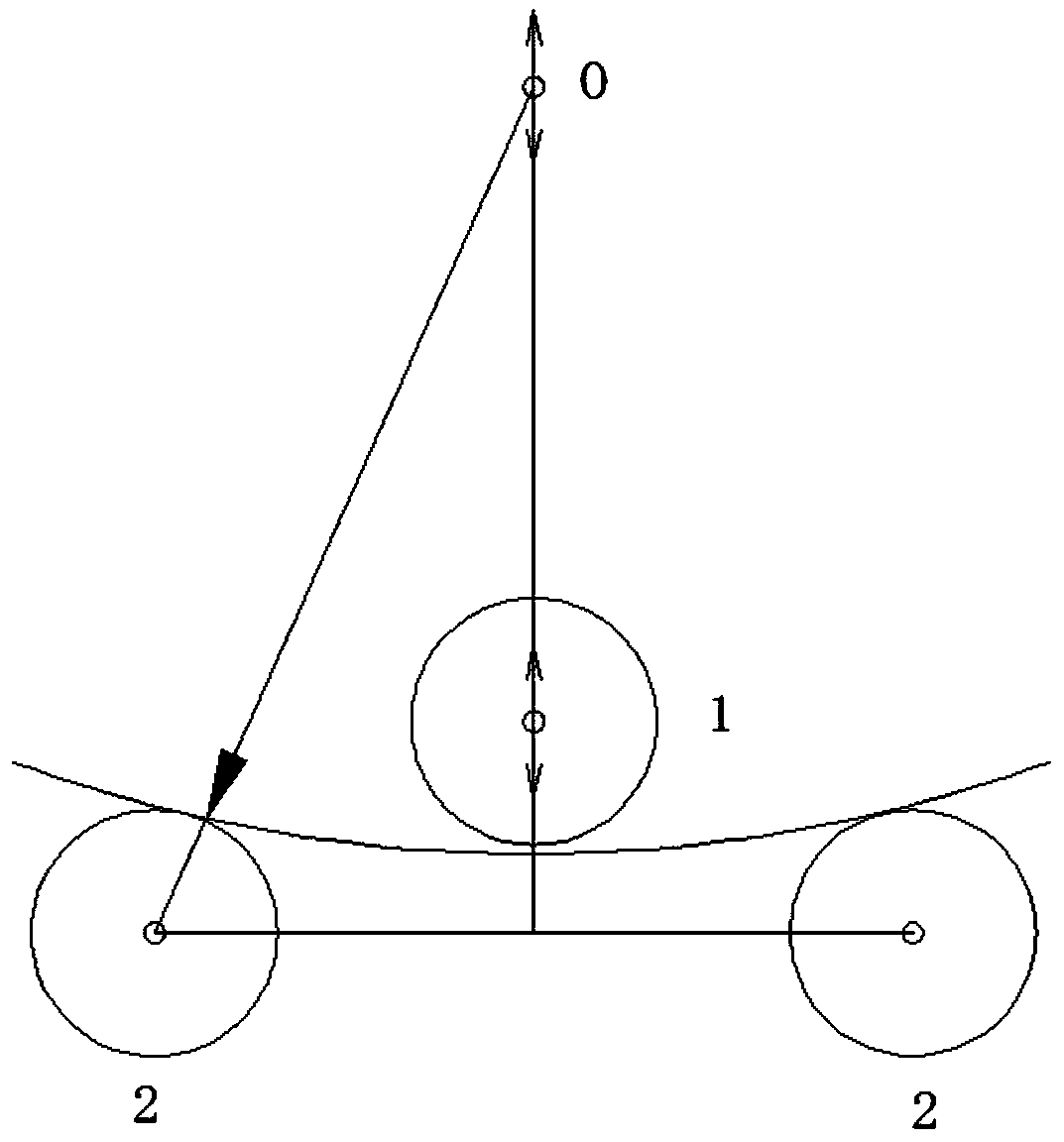

[0047] A mechanized arc-making method for arc-shaped pipeline construction. An arc-making machine is used to press the arc-shaped pipeline to be constructed. The arc-making machine includes two fixed wheels arranged symmetrically in the horizontal direction and a moving wheel moving in the vertical direction. The center of the moving wheel is located on the center line of the line connecting the centers of the two fixed wheels.

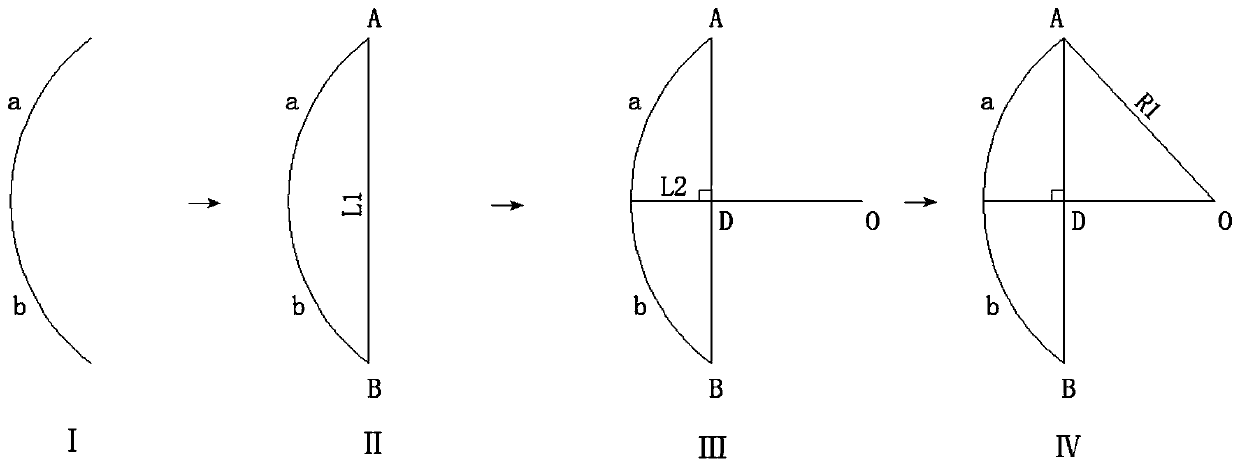

[0048] First, calculate the arc radius of the arc-shaped pipeline to be constructed according to the shape of the construction site. The arc-shaped pipeline may be one type or multiple types, and it needs to be calculated one by one when there are multiple types;

[0049] Then calculate the arc-making motor wheel fixed wheel size table according to the arc radius;

[0050] Process the arc-shaped pipe required by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com