Rotor coating production line

A production line and powder coating technology, which is used in the manufacture of stator/rotor bodies, motor generators, electrical components, etc., can solve problems such as affecting production efficiency and low degree of automation, and achieve high production efficiency, improve production efficiency, and improve automation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

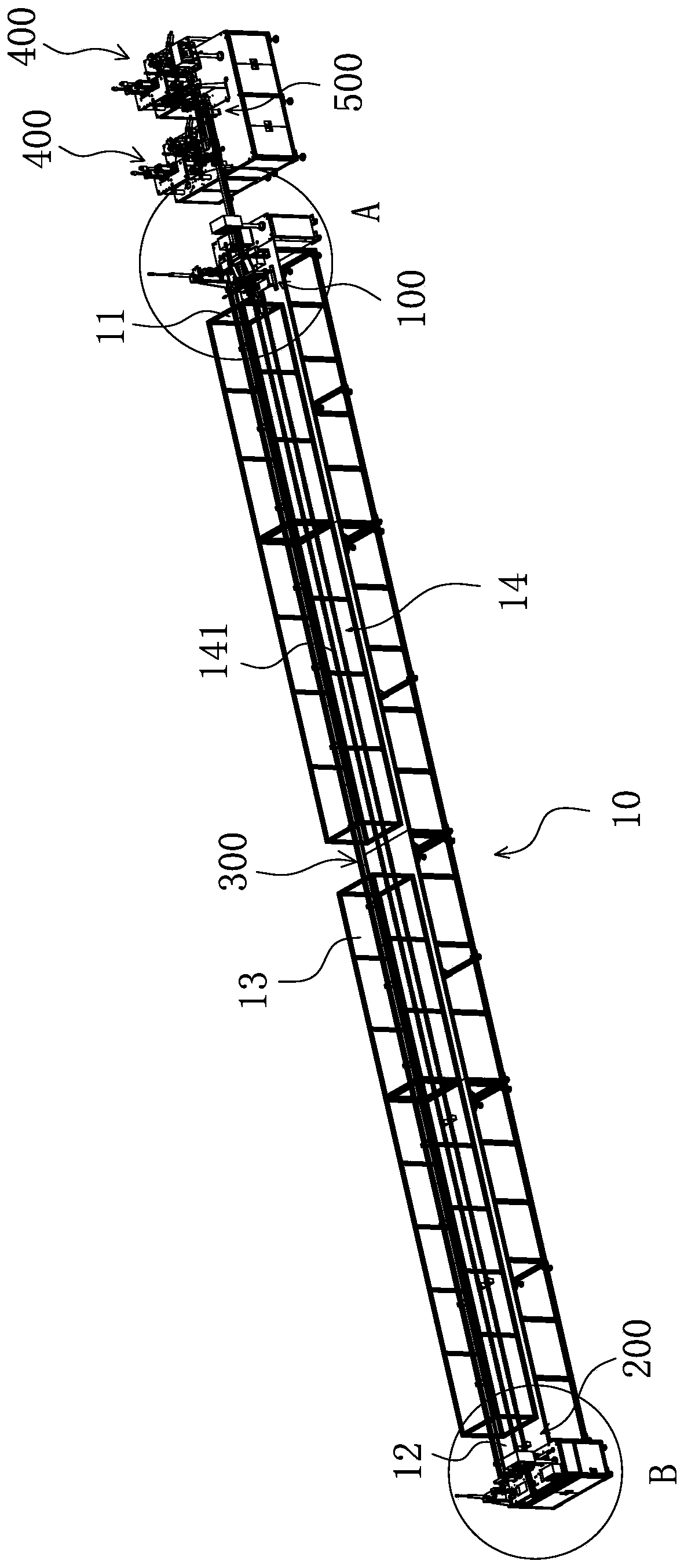

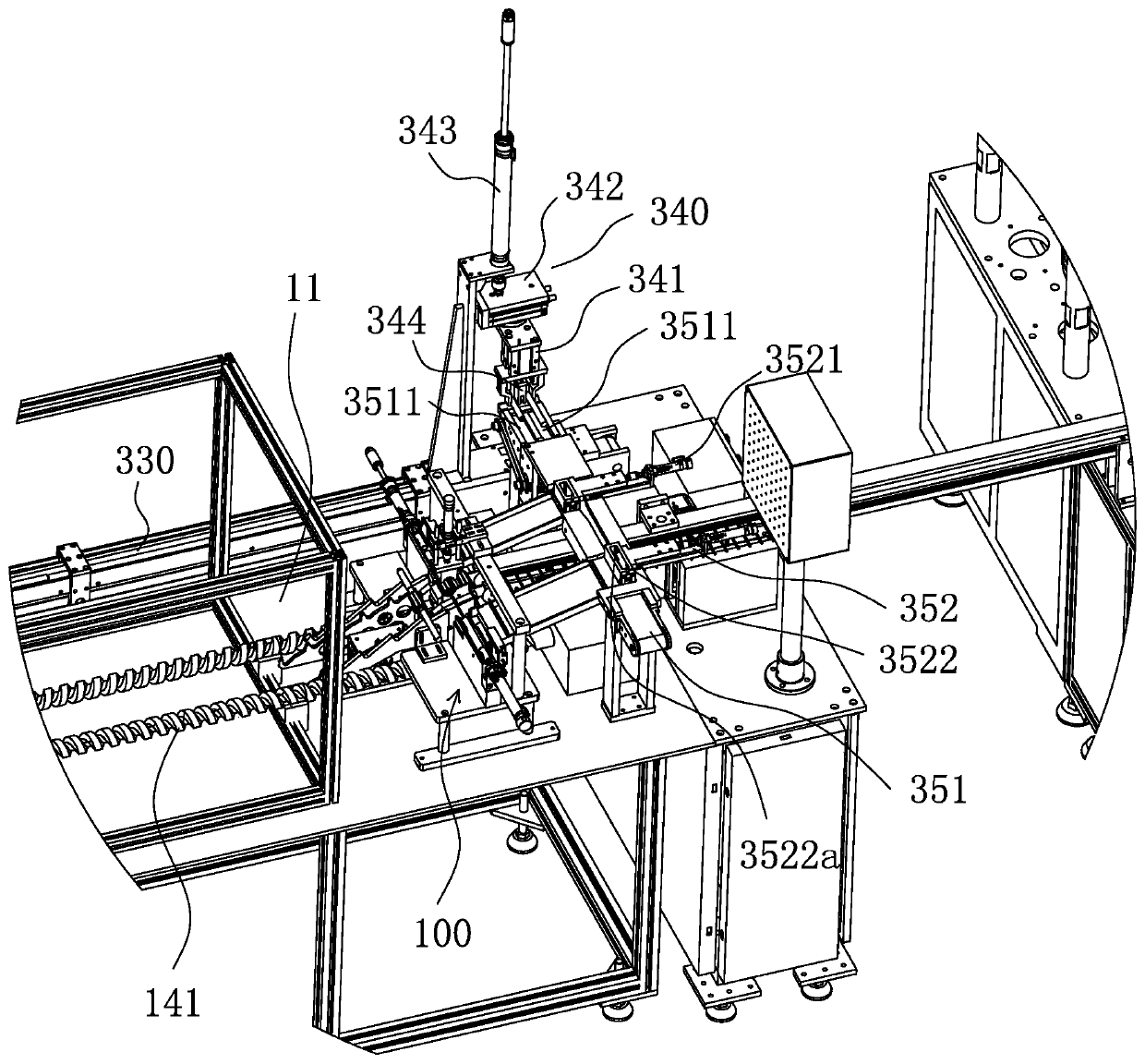

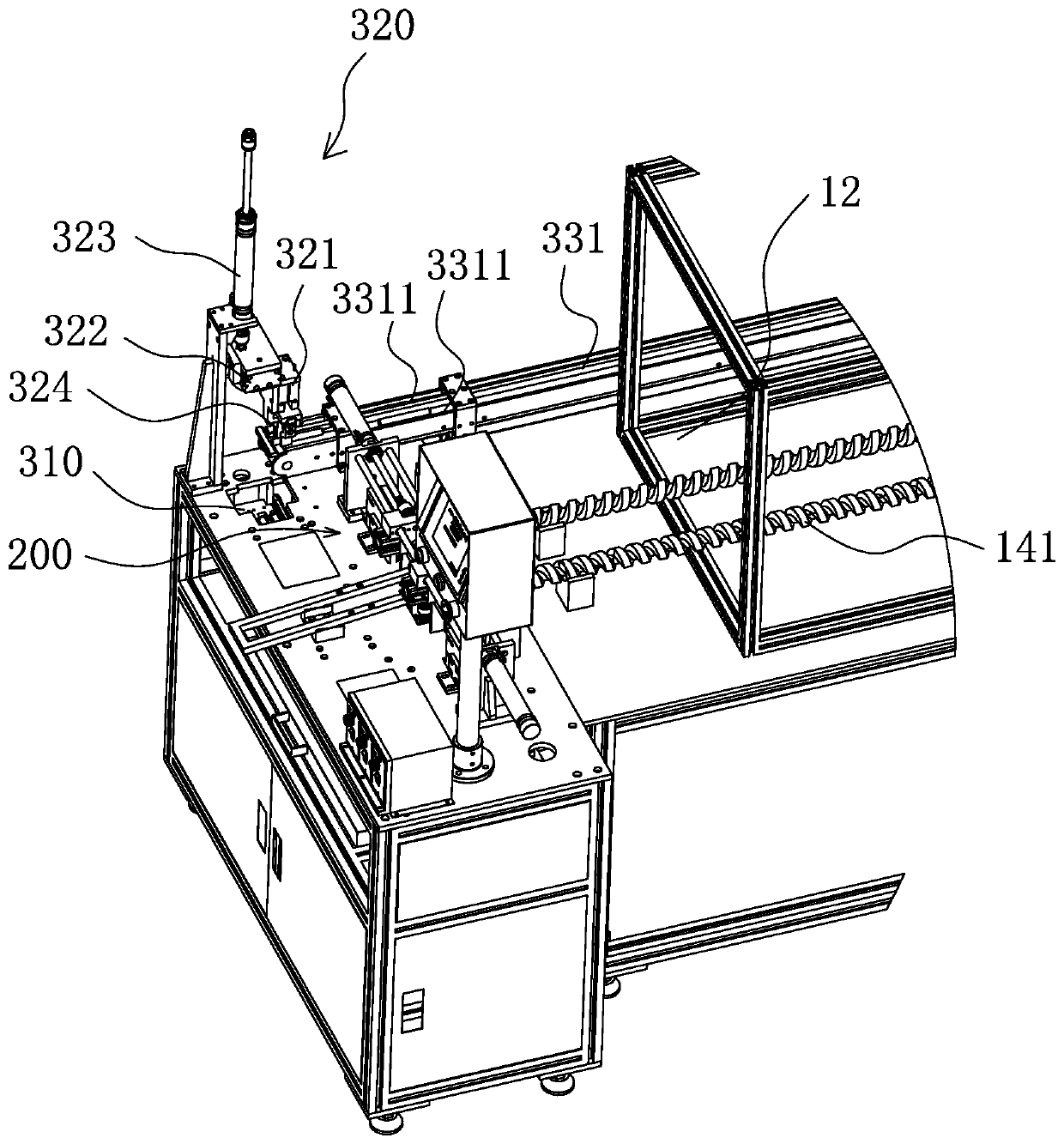

[0048] Such as Figure 1 to Figure 17 As shown, the rotor powder coating production line includes:

[0049] Frame 10, it is provided with inlet 11, outlet 12 and is located at the spray channel 13 between inlet 11 and outlet 12, inlet 11 receives workpiece 1, outlet 12 outputs workpiece 1 , the spraying passage 13 carries out the spraying process to the workpiece 1, and the conveying mechanism 14 is arranged in the spraying passage 13, and the conveying mechanism 14 conveys the workpiece 1 from the feeding port 11 to the discharging port 12, wherein, the middle part of the workpiece 1 is formed by stacking several iron sheets Cylindrical, the two ends of the workpiece 1 are rotating shafts protruding from the cylinder;

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com