Three-wheel omnidirectional moving robot platform

An omnidirectional mobile and robotic technology, applied in the field of three-wheeled omnidirectional mobile robot platform, can solve the problems of large turning radius and few degrees of freedom of the chassis, and achieve the effect of small turning radius, many degrees of freedom, and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and example.

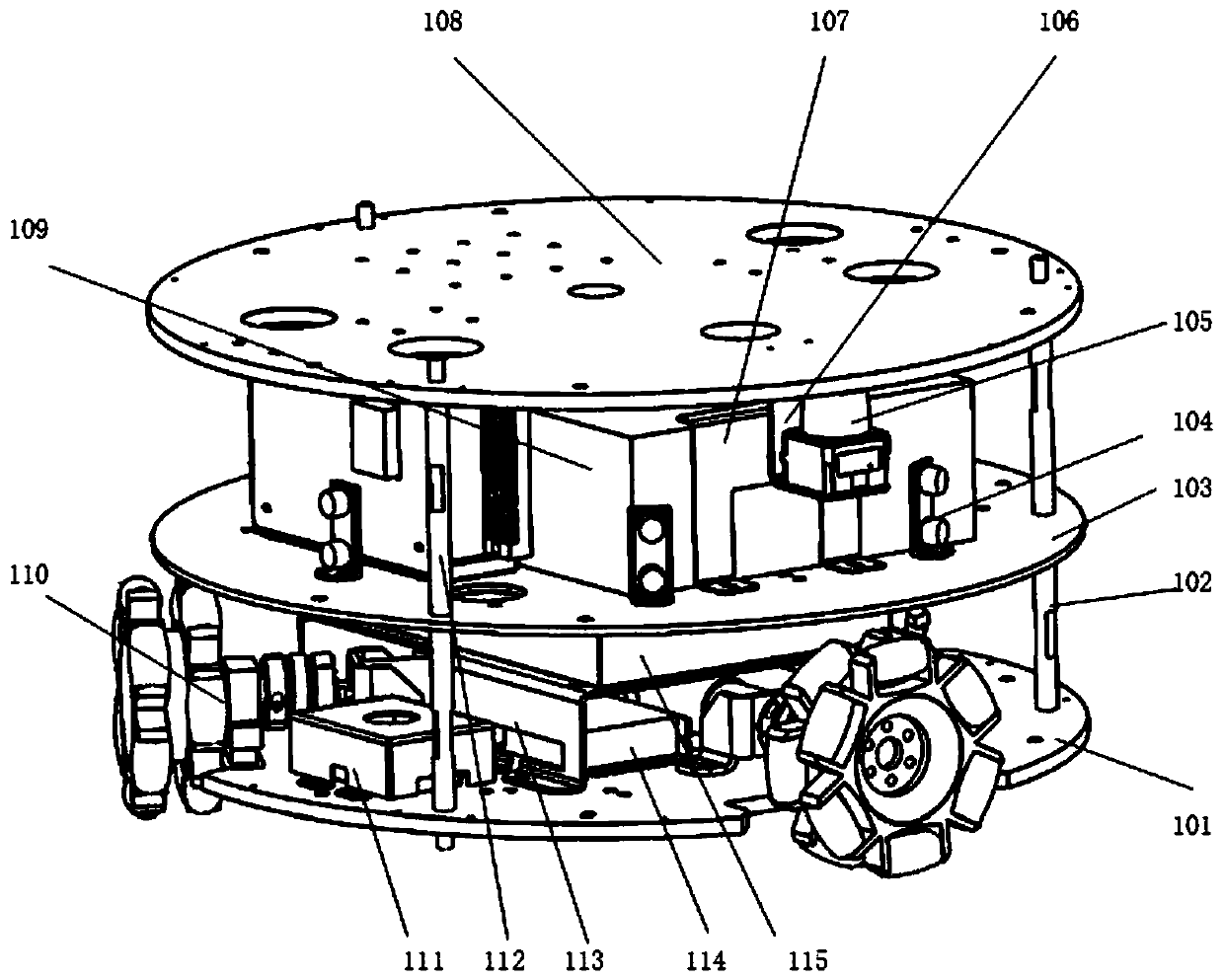

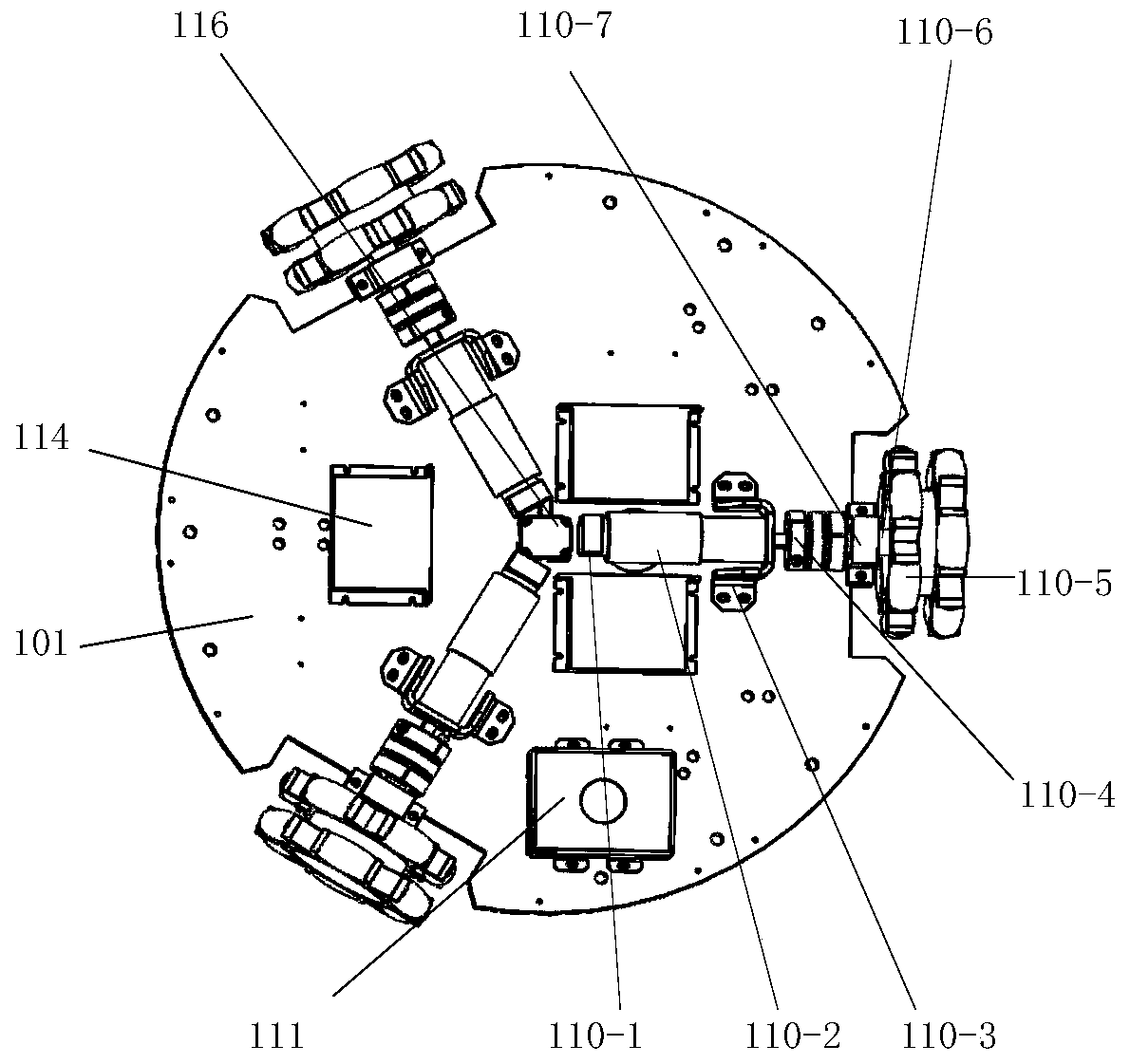

[0019] Such as figure 1 , figure 2 As shown, the omnidirectional mobile chassis 1 includes a lower mounting plate 101, a middle mounting plate 103, an upper mounting plate 108, a lower connecting column 102, an upper connecting column 112, a motor module 110, an ultrasonic sensor 104, and a laser distance measuring sensor 105 , inertial measurement unit 116 , 48V battery 109 , 12V battery 115 , controller 111 and 12V battery mounting plate 113 . The lower mounting plate 101, the middle mounting plate 103 and the upper mounting plate 108 are all circular plates, the lower mounting plate 101 and the middle mounting plate 103 are connected by three lower connecting columns 102, and the middle mounting plate 103 and the upper mounting plate 108 pass through Three upper connecting columns 112 are connected; there are three motor modules 110, which are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com