Coal slime blank production mold

A coal slime and mold technology, which is applied to the field of coal slime blank production molds, can solve the problems of inability to use combustion, incapable of efficient combustion, and inability to sell pulverized coal, and achieves the effects of simple structure, simple and convenient operation, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention will not be limited.

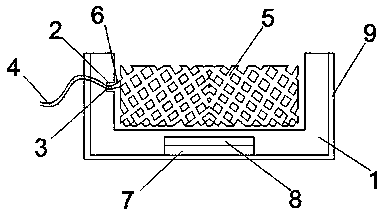

[0012] Such as figure 1 Shown, a kind of coal slime embryo production mold comprises the box mold body 1 that is provided with upper opening, and the sidewall of described box mold body 1 is provided with blind hole 2, is provided with gas injection nozzle 3 in the blind hole 2, The gas injection nozzle 3 is connected with the gas injection pipe 4 arranged on the outside of the box mold body. Inside the box mold body 1 is placed a core mold body 5 with a closed honeycomb structure composed of several tubular films that melt and shrink when exposed to high temperatures. , The mandrel body 5 is provided with an air inlet 6, the air inlet 6 is connected with the gas injection nozzle 3 and injects combustion-supporting oxygen into the mandrel body 5.

[0013] The core mold body...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap