Compensation by means of additive color

A technique for adding printing and color values, applied in the direction of power transmission devices, printing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

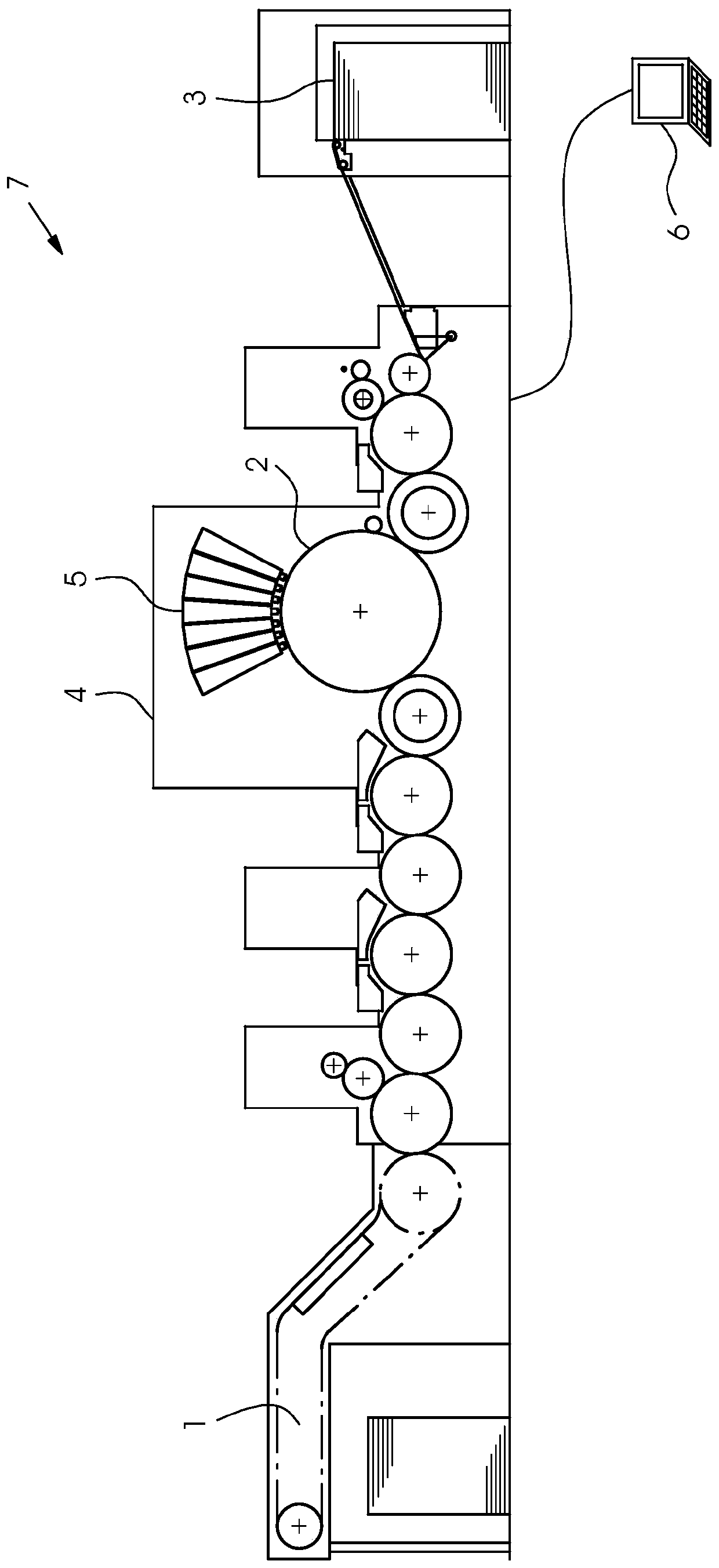

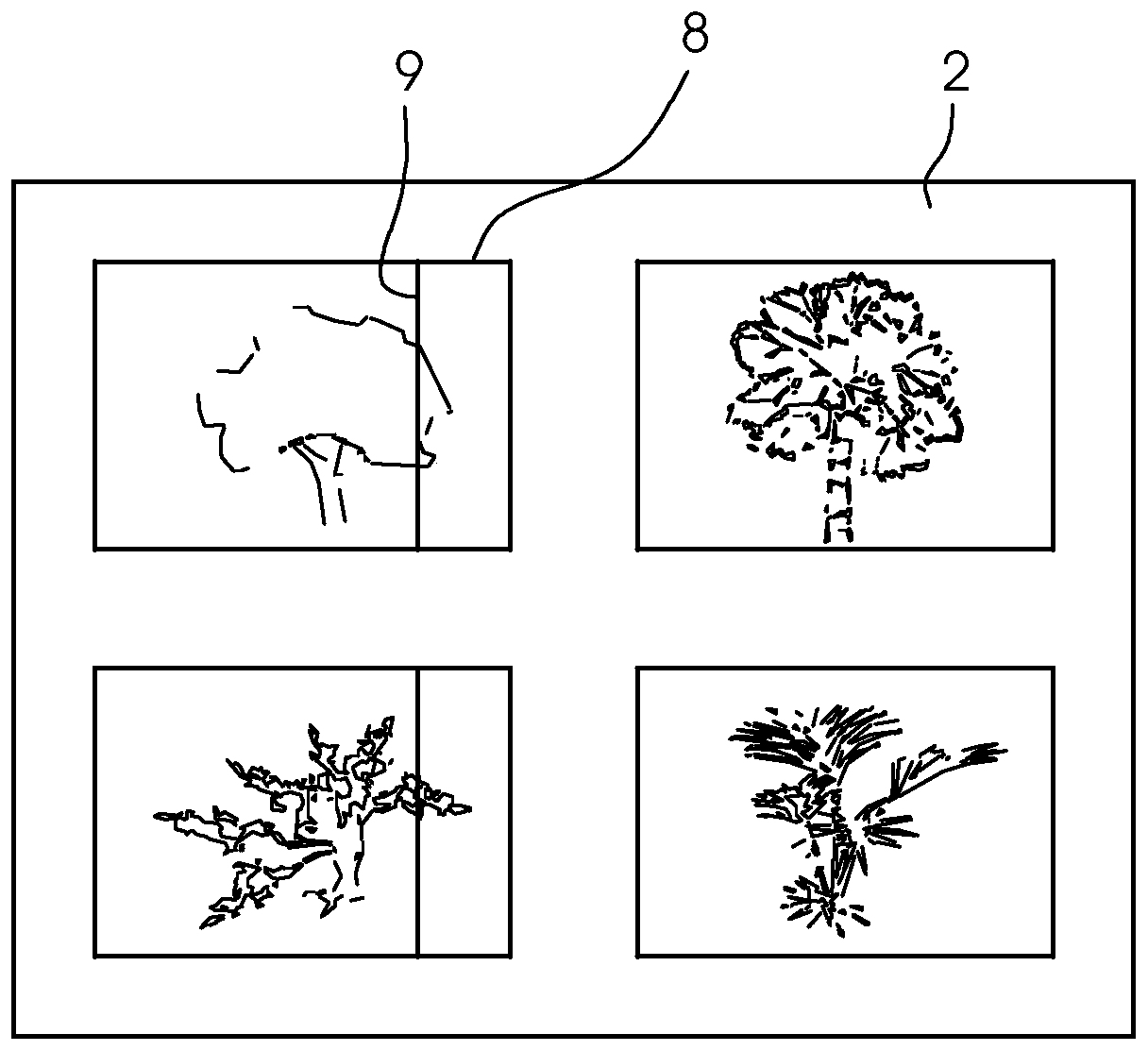

[0024] A preferred field of application for implementing the variant is the inkjet printer 7 . figure 1 An example of the basic structure of a machine 7 of this type comprising a feeder 1 for feeding a printing substrate 2 into a printing mechanism 4 where the printing substrate 2 is printed by a printing head 5 is shown in Receiver 3. Here, this is a sheet inkjet printing press 7 controlled by a control computer 6 . As already described, during operation of the printing press 7 it may occur that individual printing nozzles in the printing head 5 of the printing unit 4 fail. The consequence is white lines 9 or, in the case of multicolor printing, distorted color values. figure 2 An example of such a white line 9 is shown with a printed image 8 .

[0025] In its preferred embodiment, the invention describes a method for compensating white lines 9 which can also be used in addition to other methods. The important difference is that the resulting white line 9 is compensated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com