Large steel pipe temporary transfer device for building

A transfer device, construction technology, applied in transportation and packaging, multi-axle trolleys, trolley accessories, etc., can solve the problems of large size, high cost and inconvenient operation of cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

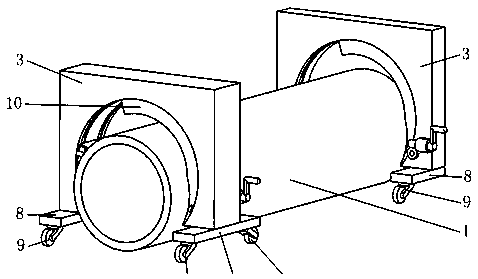

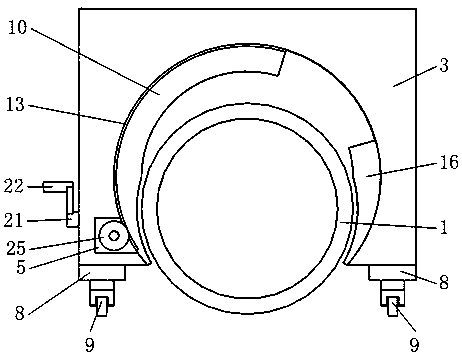

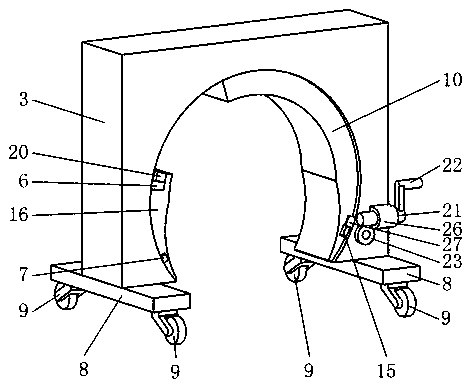

[0026] Such as image 3 , 4 , 5, it includes door frame 3, block A6, block B7, holding plate A10, block C15, holding plate B16, block D20, worm 21, worm wheel 23, rotating shaft 24, gear 25, wherein as figure 1 , 2 As shown in , 3, a mobile device is installed on the door frame 3; as figure 2 ,3 , 4, the arc-shaped holding plate A10 and the arc-shaped holding plate B16 slide on the arc-shaped inner wall of the door frame 3 around their respective arc center axes respectively; Figure 7 As shown, two clamping blocks C15 are installed symmetrically on both sides of the holding board A10; image 3 , 4 , 6, the two clamping blocks C15 respectively cooperate with the two clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com