Laser cladding device for repairing main drive runway of shield tunneling machine

A laser cladding, main drive technology, used in grinding/polishing equipment, metal processing equipment, grinding racks, etc., can solve errors, affect the service life and performance of shield machine main drive runway, laser cladding equipment Problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

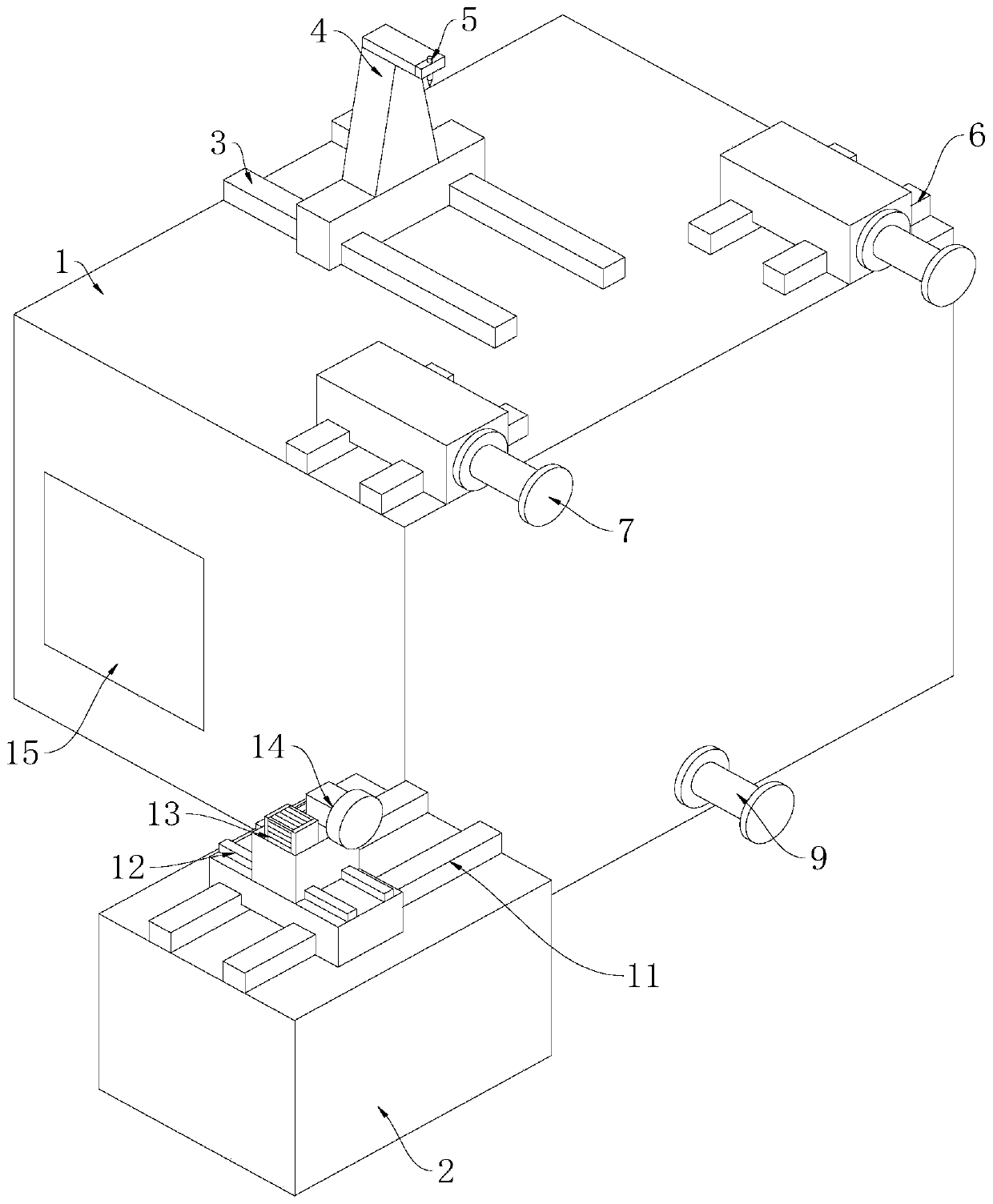

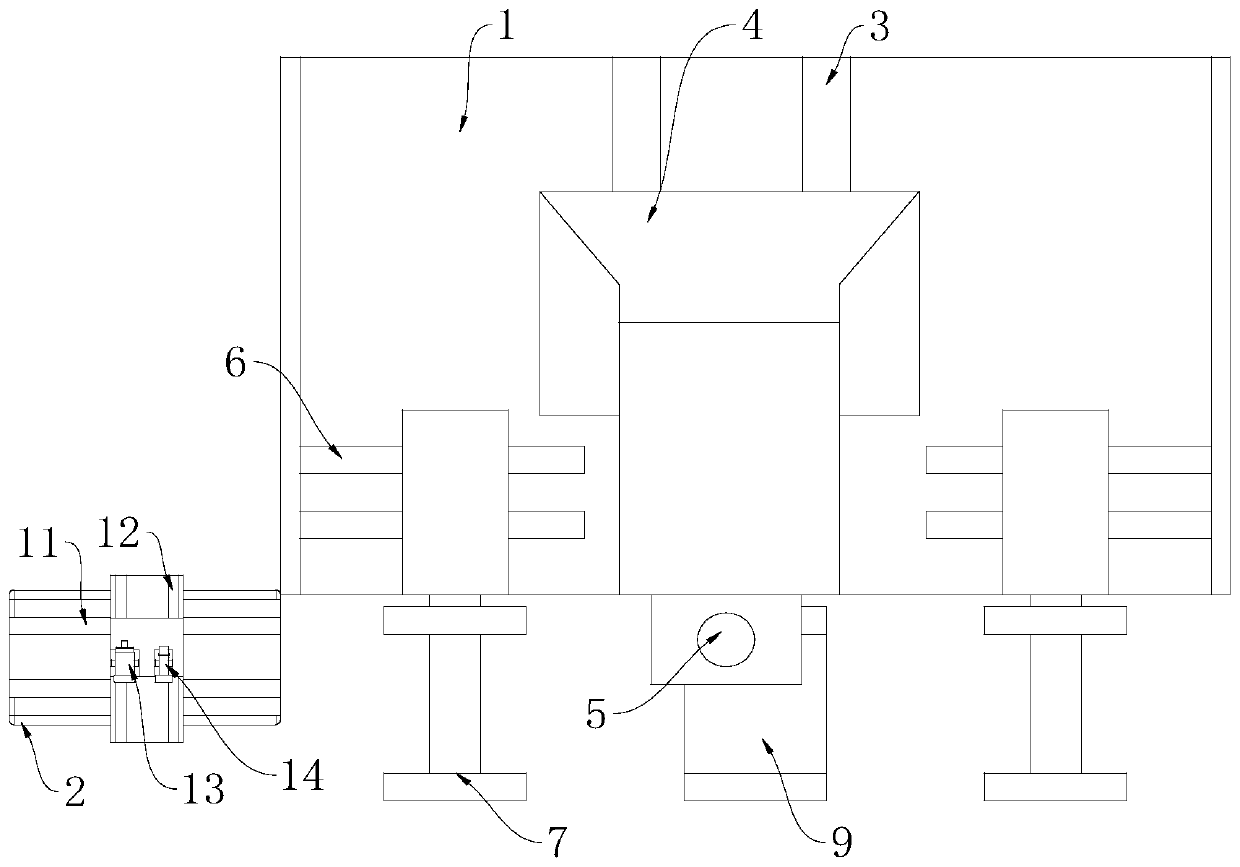

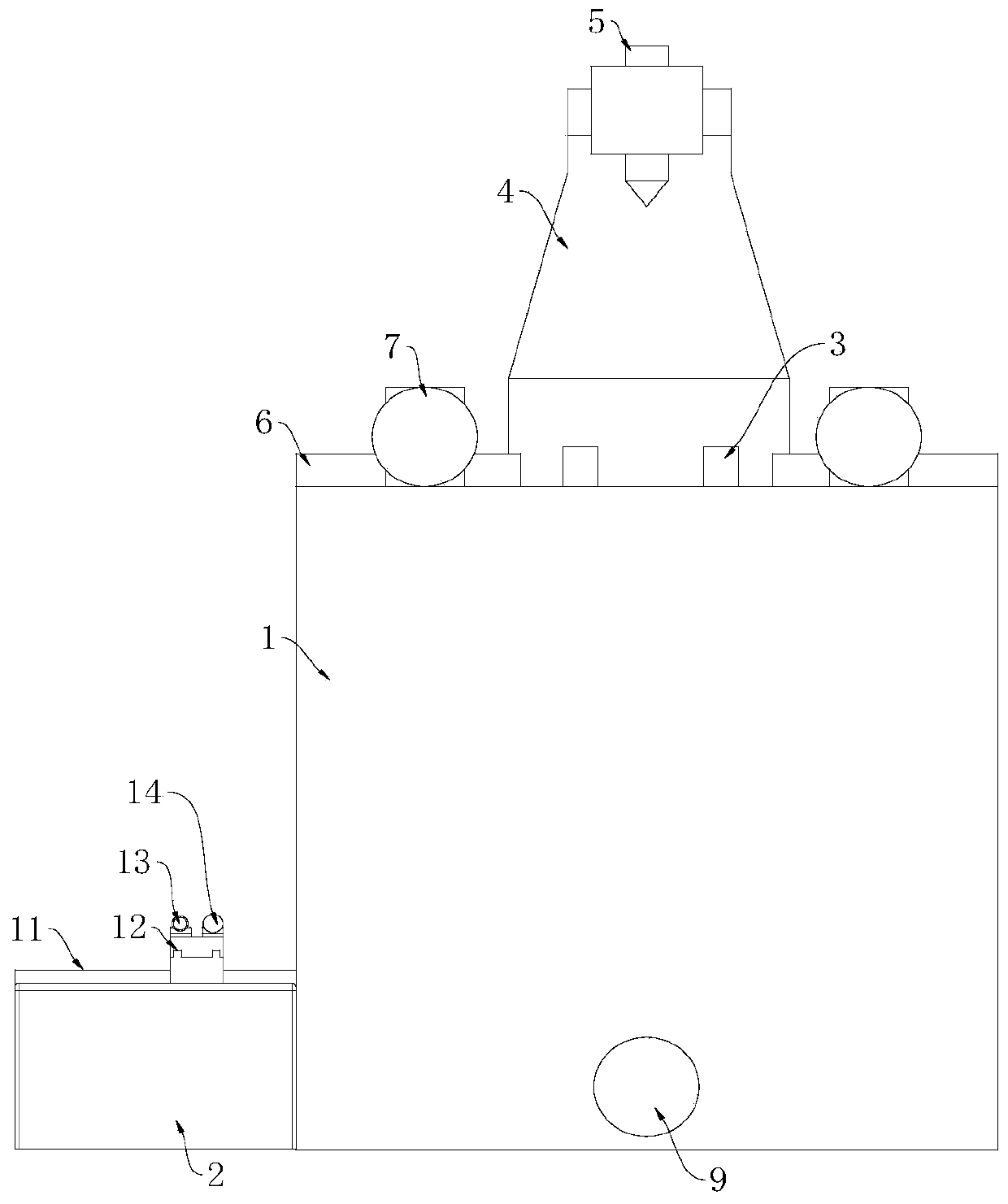

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention is a device for repairing the laser cladding of the main driving runway of the shield machine, including a working platform 1 and a cushion block 2, the cushion block 2 is fixed at a corner of the working platform 1, and the top of the working platform 1 The middle part is fixed with the first electric sliding table 3, the top of the first electric sliding table 3 slider is fixed with an L-shaped fixed frame 4, the top of the front of the L-shaped fixed frame 4 is fixed with a laser cladding head 5, and the working platform 1 The two corners on the front side of the top are fixed with a diameter adjustment mechanism. The diameter adjustment mechanism includes a second electric slide 6 and a support roller 7. The bottom end of the second electric slide 6 is fixed to the top of the working platform 1. Connected, the supporting roller 7 is rotated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com