Brush type sealing structure allowing rotor to reverse

A brush-type seal and rotor technology, which is applied to the sealing device of piston pumps, to prevent leakage, and to engine components, etc., can solve problems such as damage to brush wires, and achieve the effects of reducing use costs, increasing service life, and being easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

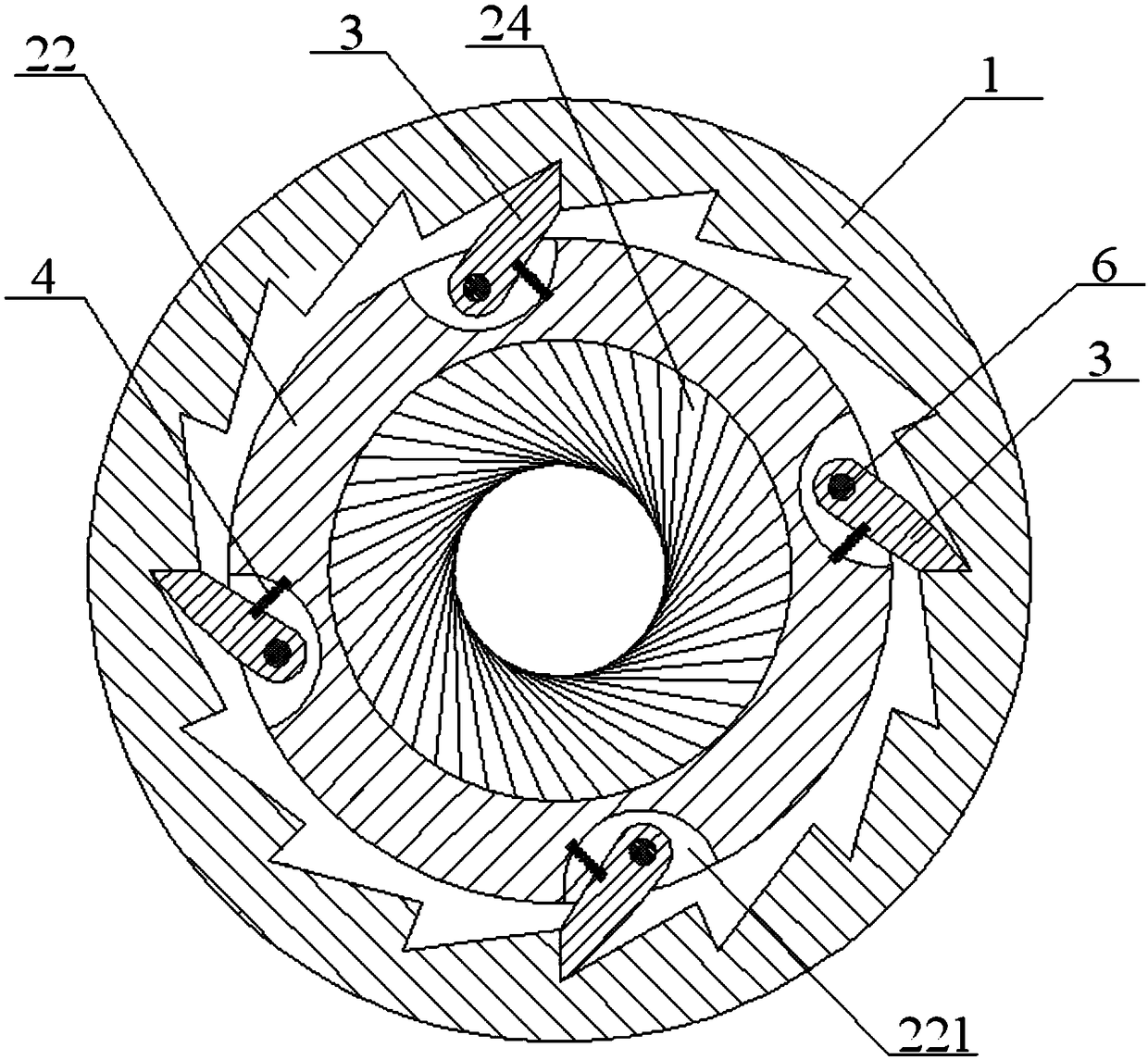

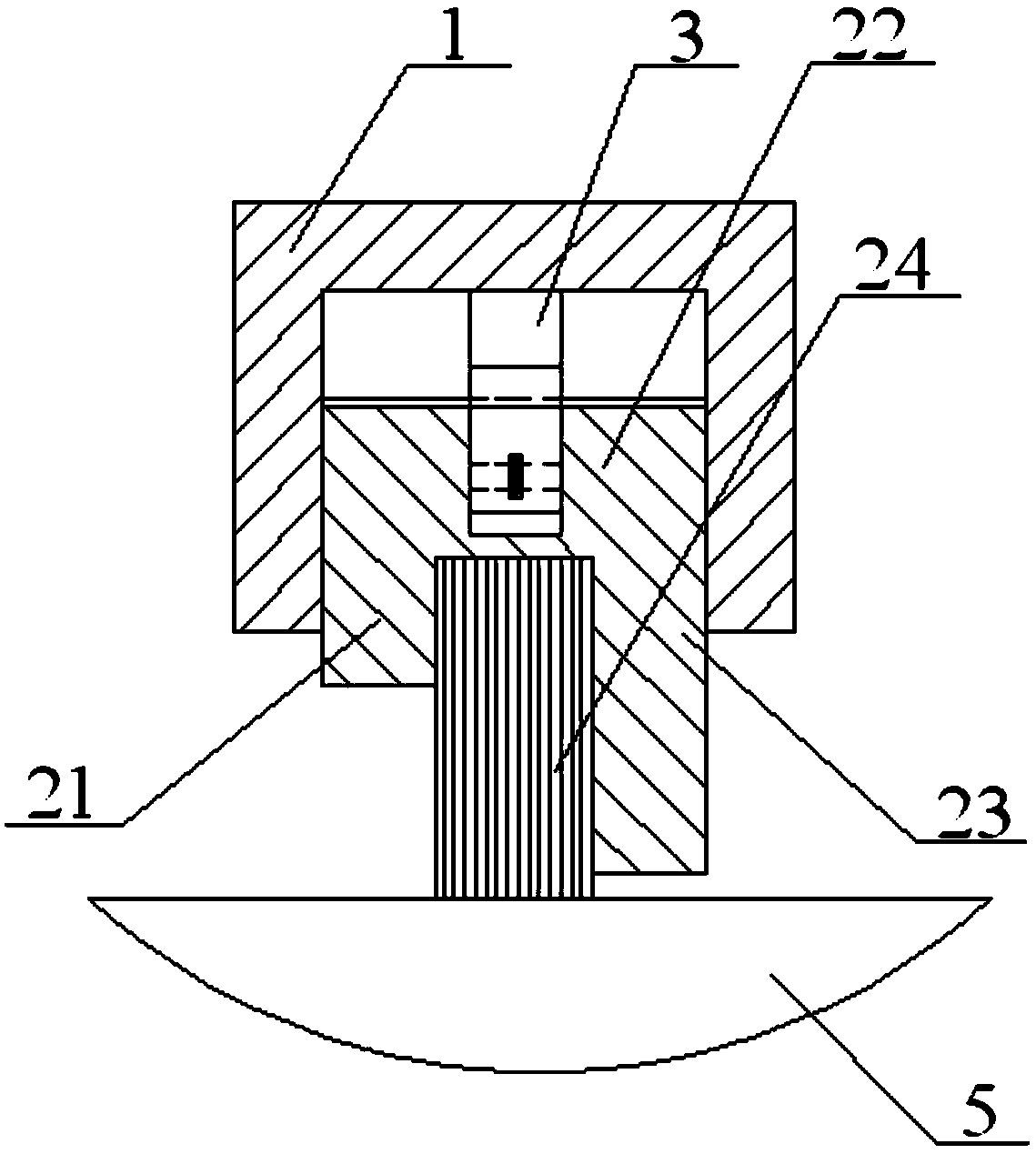

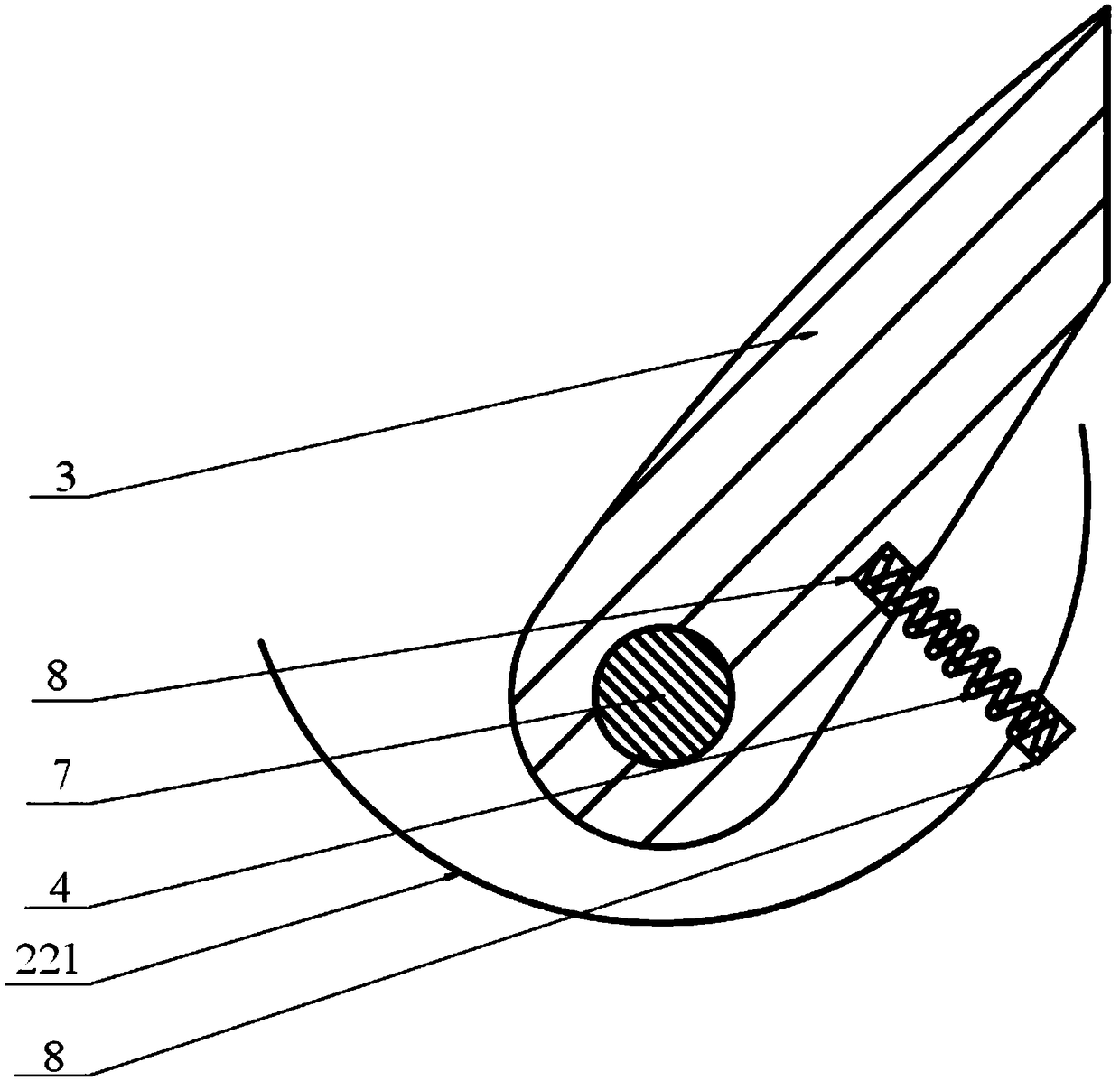

[0020] Such as Figure 1 to Figure 3 As shown, the present invention provides a brush seal structure that allows the reverse rotation of the rotor, including: a stator 1, a brush seal, a pawl 3, a coil spring 4 and a rotor 5, wherein the stator 1 is ring-shaped, and its The inner circumference is serrated, and the brush seal is arranged in the interior of the stator 1 with a gap fit. The brush seal includes a front baffle 21, a connection area 22, a rear baffle 23 and a brush wire bundle 24 integrally connected. The tow 24 is sandwiched between the front baffle 21 and the rear baffle 23, one end is fixedly connected to the connection area 22, and the other end is arranged obliquely along the rotation direction of the rotor 5, and the outer periphery of the connection area 22 is evenly provided with arc-shaped grooves 221 On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com