Composite material thin shell plane folding and unfolding device and folding and unfolding method

A composite material and thin shell technology, applied in the field of mechanical structure, can solve the problems of heavy weight, complex structure, and many parts, etc., and achieve the effects of high space utilization, simple structure, and large specific strength and specific modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

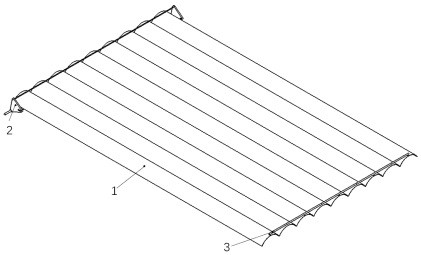

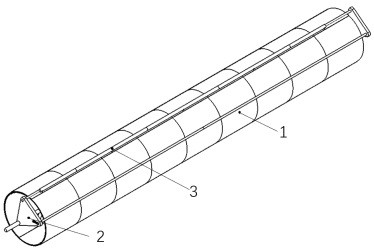

[0031] Such as Figure 1-8 As shown, a plane folding device for a thin composite shell includes a thin composite shell 1, a folding mechanism 2, and an end support arm 3. The folding mechanism is installed on one side of the composite shell, and the end support arm is installed on the composite On the opposite side of the installation position of the material thin shell folding mechanism;

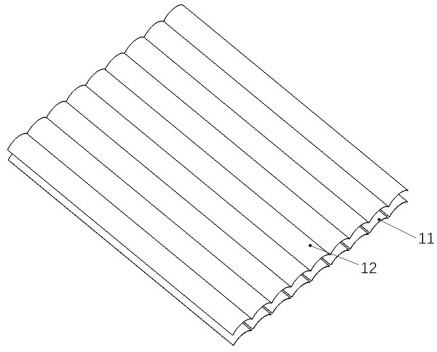

[0032] The composite material thin shell includes a structural layer 11 and a connecting layer 12. The structural layer is composed of at least two arc bistable composite material tape structures juxtaposed. The connecting layer is a flexible film or fabric bonded on one side or both sides of the structural layer. side surface, and connect the structural layers into a whole; by adjusting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com