A stable clamping arch installation machine

An arch installation machine and clamping technology, which is applied to shaft equipment, shaft lining, mining equipment, etc., can solve the problems of reducing stroke efficiency, failing to operate strokes, and not considering energy consumption, flexibility, installation, and increased energy consumption. Achieve the effects of improving energy utilization and working power, saving materials and load weight, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

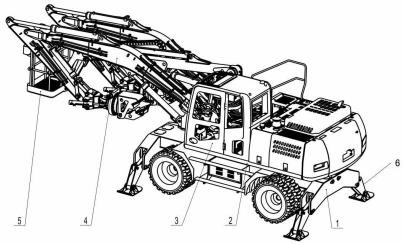

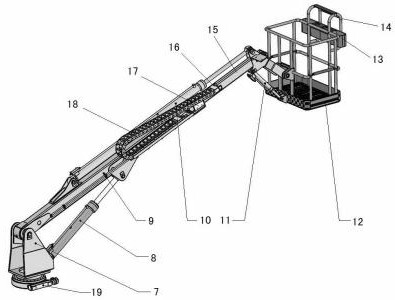

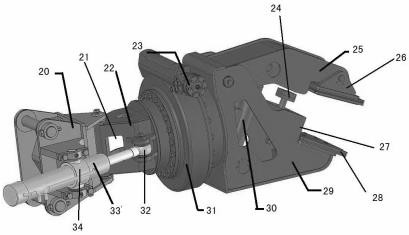

[0038] As shown in the figure: a stable clamping arch installation machine, including a storage frame, a chassis, a cockpit, a clamping arm, a basket assembly, a leg, a connecting frame, a hollow part, a swing arm, a hydraulic motor, and a limit Protrusion, upper splint, triangular block, shoulder, upper backing plate, lower backing plate, lower clamping block, clamping cylinder, slewing mechanism, cylindrical connection piece, swing arm cylinder, ring connection piece; the hanging basket assembly includes the support , Pitch cylinder, outer arm, telescopic cylinder, leveling cylinder, hanging basket, back body platform, escalator, inner arm, first joint, second joint, crawler belt, rotary drive mechanism;

[0039] As shown in the figure: the cockpit is provided above the underframe, a gondola assembly is provided in the middle of the front of the cockpit, a clamping arm is provided on both sides of the gondola assembly, and a clamping arm is provided at the front and rear of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com