Automatic photosensitive film washing equipment

A photosensitive film and film technology, applied in the field of imaging, can solve problems affecting work efficiency, pollution, unfavorable promotion and use, etc., and achieve the effects of improving the washing effect and efficiency, reducing costs, and facilitating the promotion and use of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

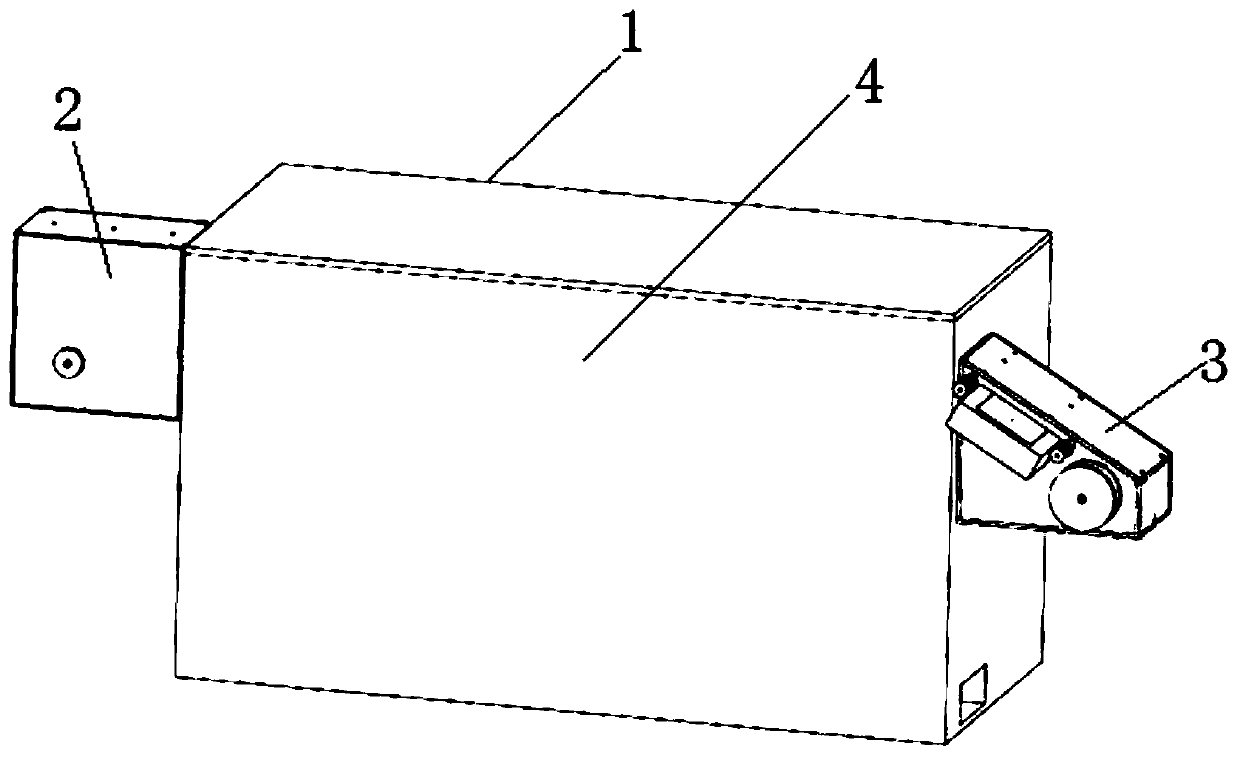

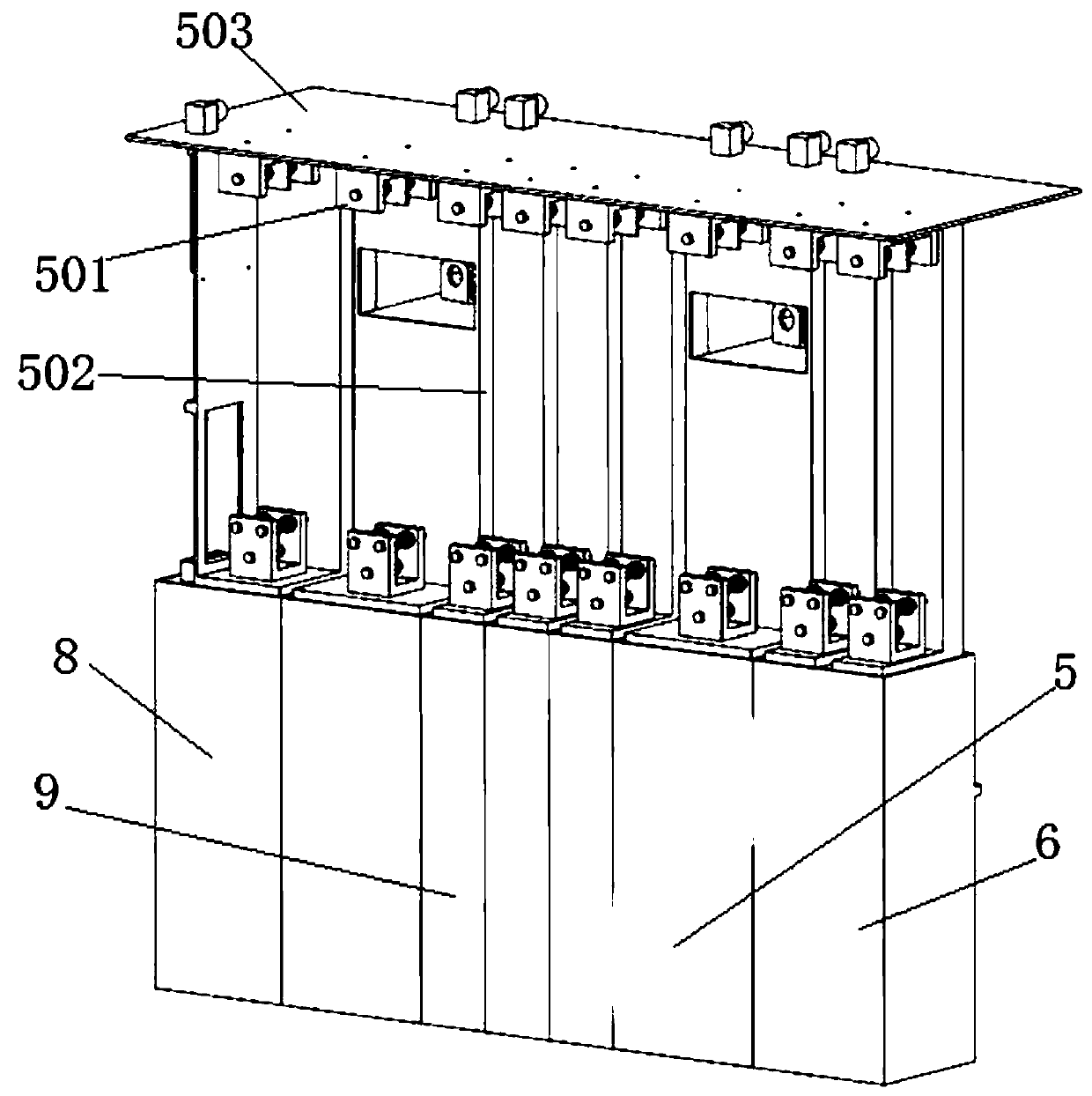

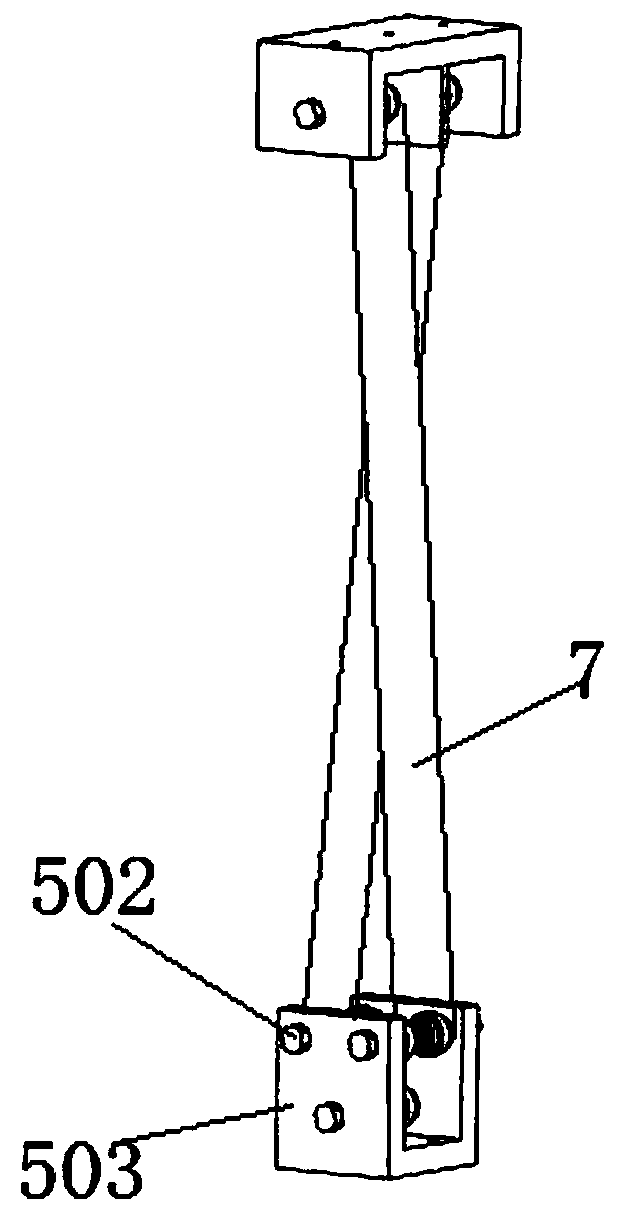

[0025] A kind of automatic photosensitive film developing equipment, see figure 1 and figure 2 , including the body of the box structure 1, the film output bin 2, the film receiving bin 3, the film washing and drying area 4, the washing assembly 5, the electric control system, the water temperature control system, the thermal drying system 6, the high-pressure jet system and water inlet and outlet pipes; the film output bin 2 is installed on the left side of the fuselage 1, the film receiving bin 3 is installed on the right side of the fuselage 1, the film washing and drying area 4 is installed in the middle of the fuselage 1, and the film washing The drying area 4 includes a developing tank, a fixing tank, a washing tank and a drying tank; the body 1 of the box structure, the film output bin 2 and the film washing and drying area 4 are all set as airtight and light-proof structures.

[0026] The automatic photosensitive film developing equipment of the present embodiment ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com