Battery module with a plurality of battery cells

A technology for battery cells and battery modules, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as reduced service life, and achieve the effects of large wetting area, reliable temperature regulation, and sufficient mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

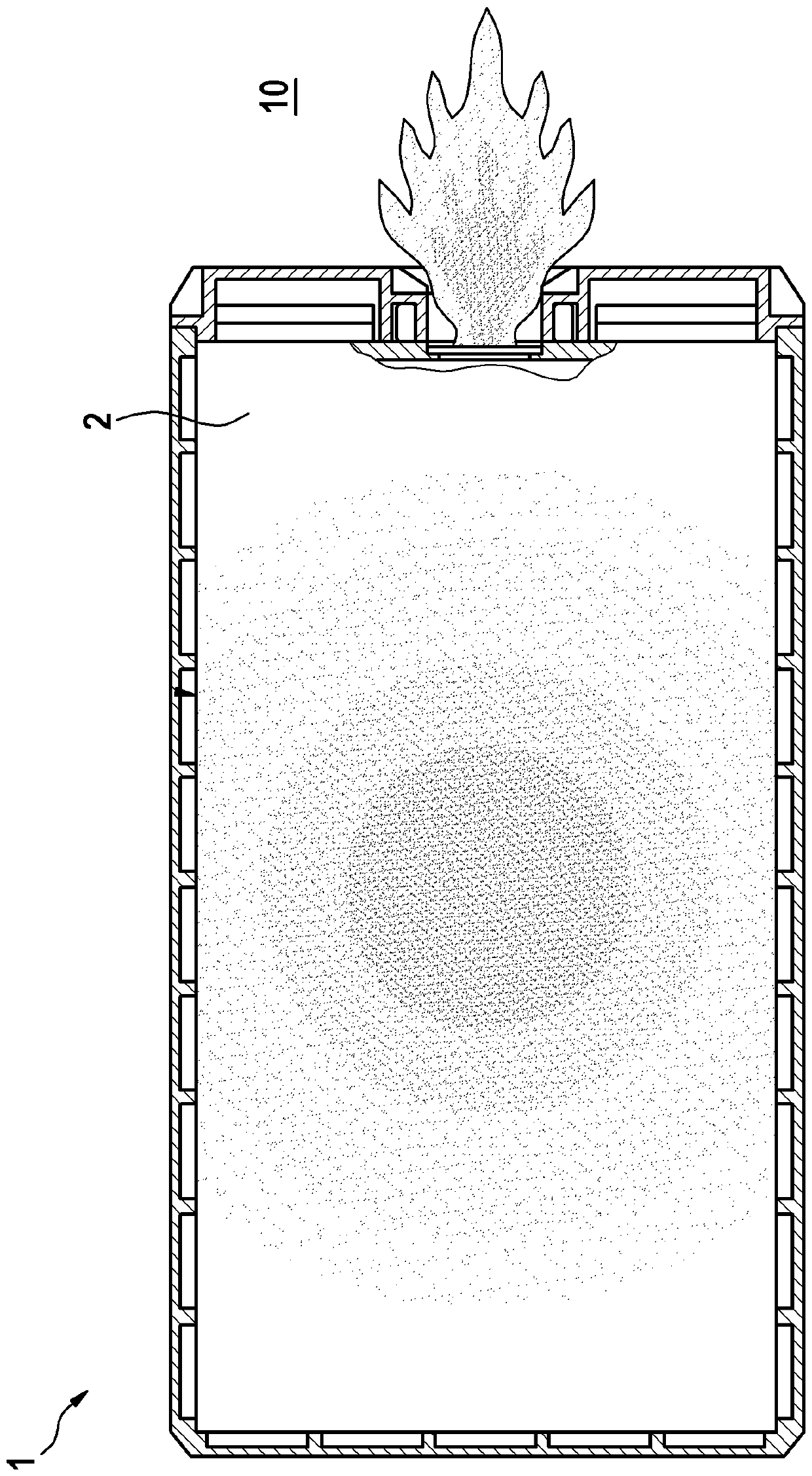

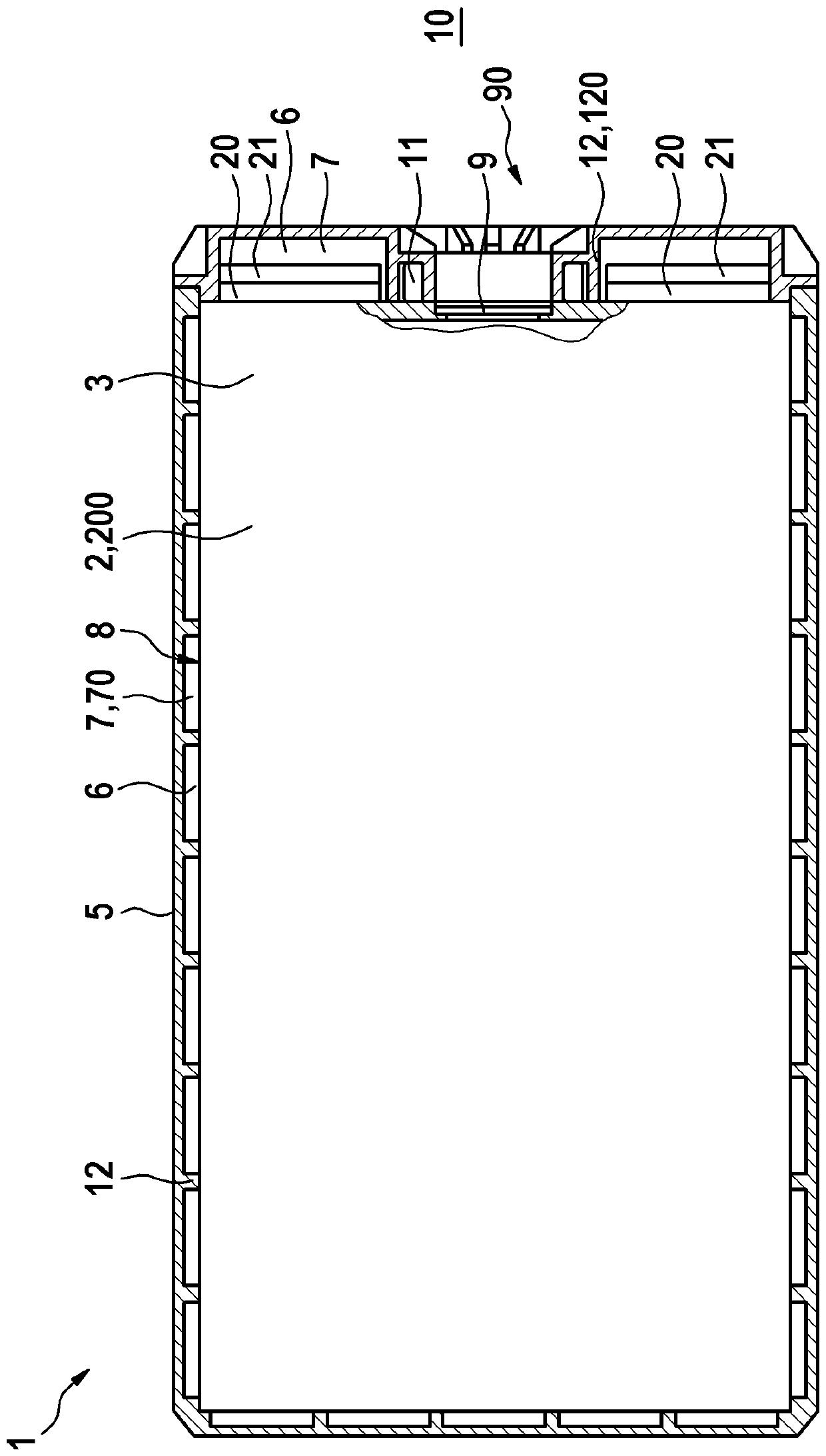

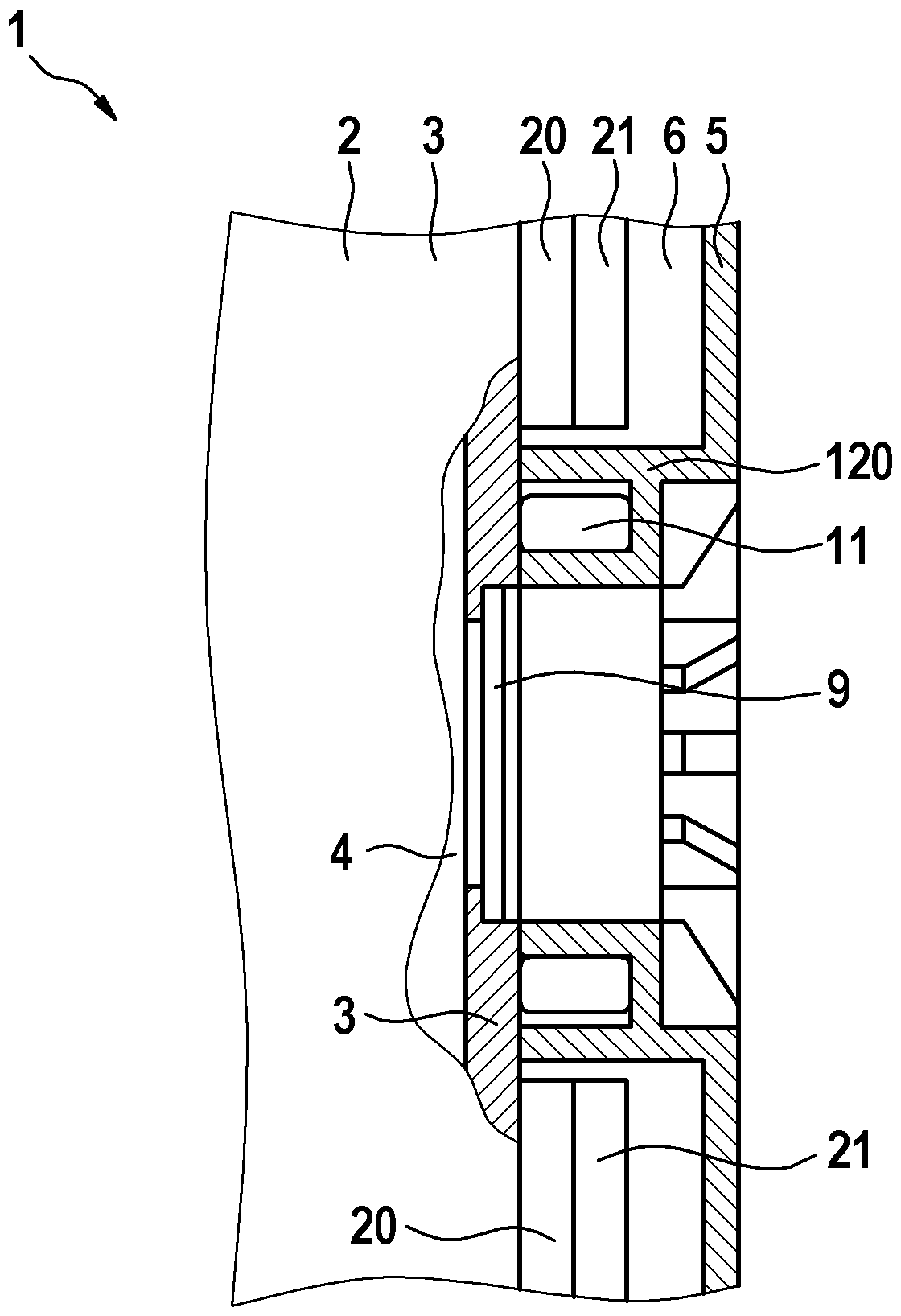

[0052] figure 1 An embodiment of a battery module 1 according to the invention is schematically shown in a sectional view from the side.

[0053] The battery module 1 includes at least one battery cell 2 which has a battery cell housing 3 .

[0054] In this case, the electrochemical components 4 of at least one battery cell 2 are accommodated in the battery cell housing 3—in the figure 1 cannot be identified in .

[0055] In this case, the electrochemical component 4 of the at least one battery cell 2 can comprise, for example, a cathode element, an anode element and a separator element.

[0056] Furthermore, the battery module 1 includes a battery module housing 5 . In this case, at least one battery cell 2 is accommodated in the battery module housing 5 .

[0057] Here, from figure 1It can be seen in the sectional view that a temperature-control fluid receptacle 6 is formed between the battery module housing 5 and the battery cell housing 3 of at least one battery cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com