Bidirectionally rotary lipstick box

A two-way rotation, lipstick box technology, applied in the direction of packaging items, applications, special packaging items, etc., can solve the problems of inability to rotate relatively, inconvenient, affecting users' use, etc., to extend service life, improve reliability, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further specifically described below through specific implementation modes (embodiments) and in conjunction with the accompanying drawings.

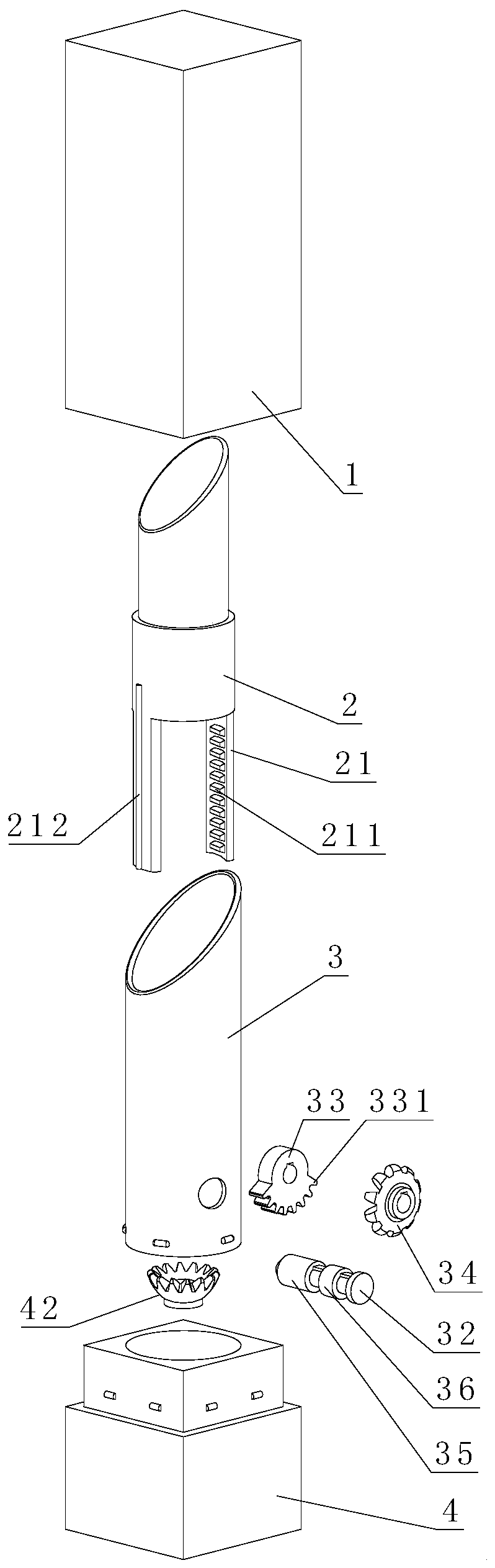

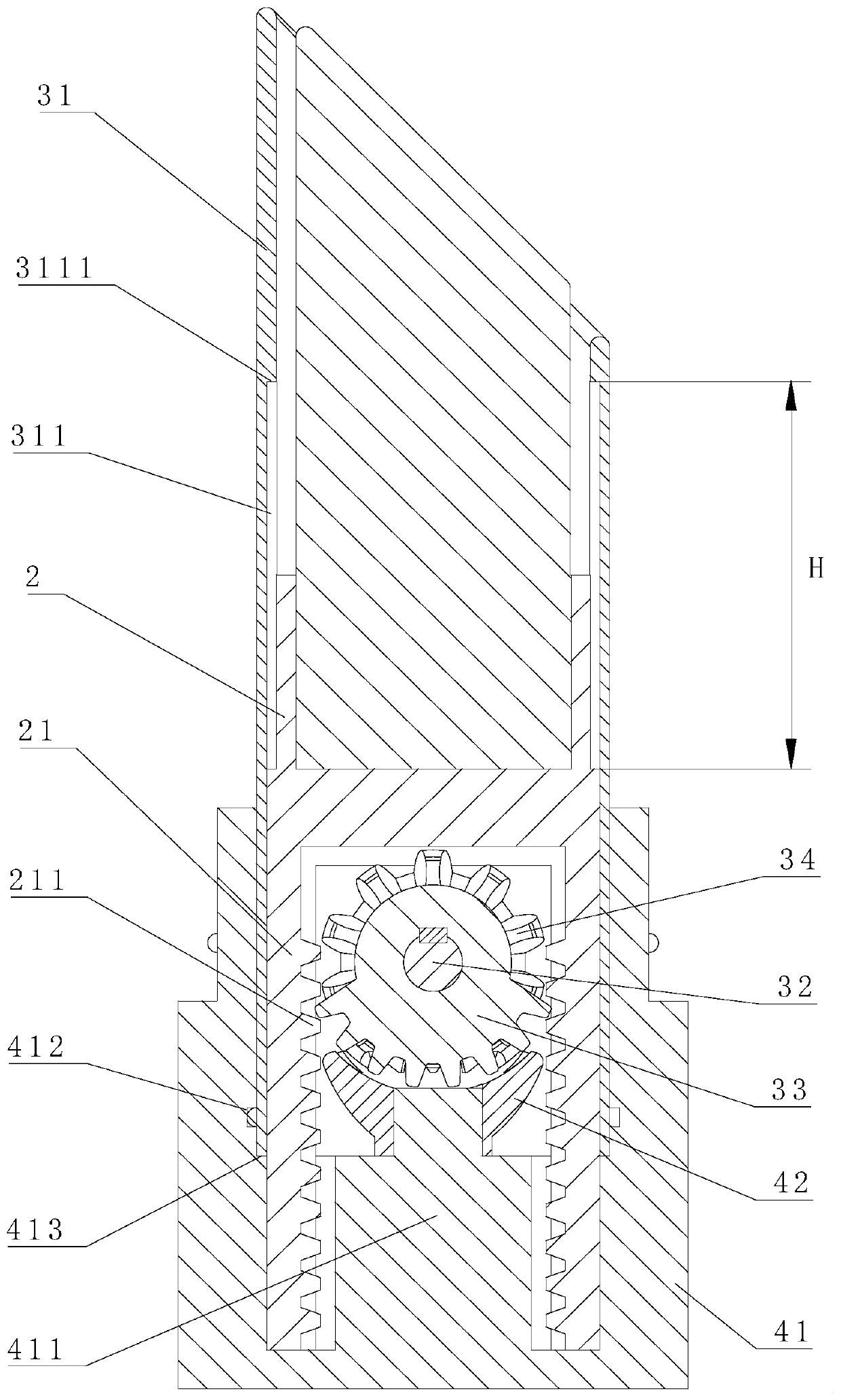

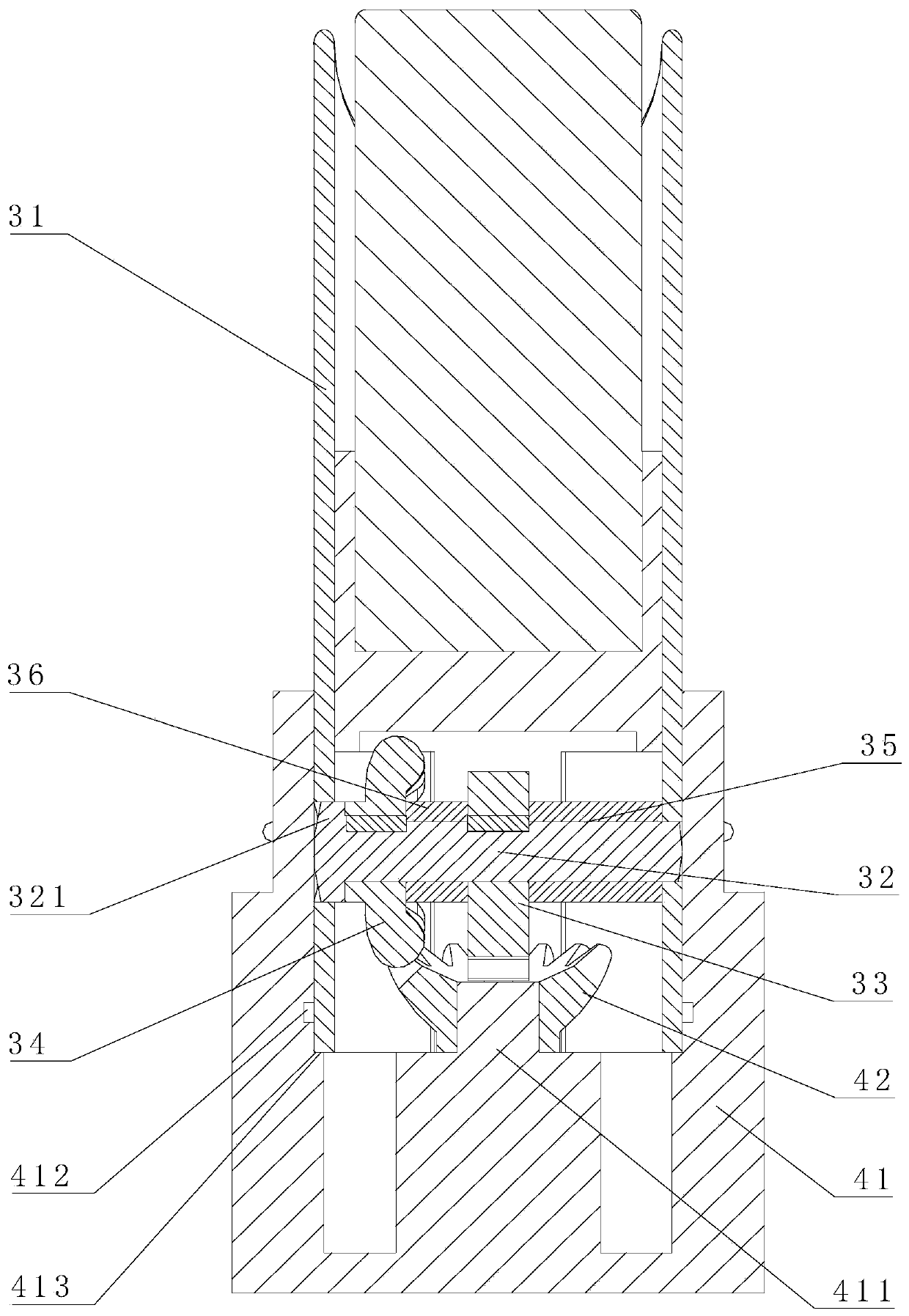

[0029] A traditional lipstick box mainly includes a top cover 1, a lipstick paste holder 2, a sleeve assembly 3 and a rotating base assembly 4, see Figure 1-8 The outer periphery of the lower end of the lipstick paste bracket 2 of the two-way rotary lipstick box provided by the present invention is provided with two oppositely arranged protruding ends 21, and the inner side of the protruding ends 21 is provided with a rack 211; the sleeve assembly 3 includes Sleeve 31, the sleeve 31 is a circular tube with the upper end chamfered, the lower part of the sleeve 31 is provided with a rotating shaft 32 passing through the center of the sleeve 31, and the two ends are framed on the side wall of the sleeve 31, the rotating shaft 32 The middle part is fixedly connected with a secto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com