Injection mold for fixed mold sliding block of mobile phone rear cover

A technology for the back cover of a mobile phone and an injection mold, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as the inability to meet the process requirements of molded products, and achieve good molding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

[0014] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

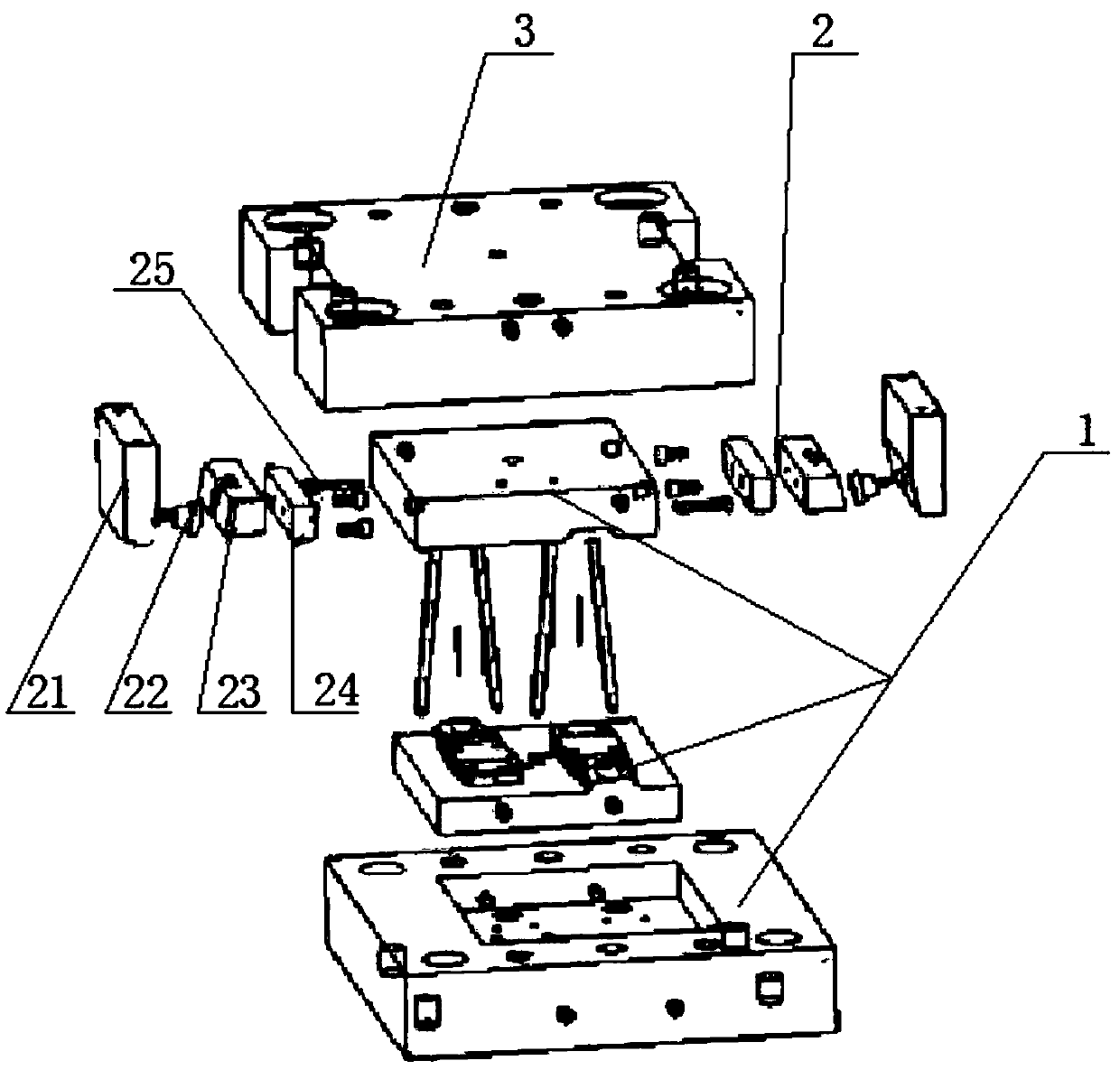

[0015] Such as figure 1 As shown, the present invention provides a mobile phone back cover fixed mold slider injection mold, including a fixed mold body 1, a fixed mold forming mechanism 2 arranged on the side of the fixed mold body 1, and a movable mold 3 adapted to the fixed mold body 1 The fixed mold forming mechanism 2 is respectively arranged on the left and right sides of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com