Three-dimensional flexible composite foam material with concave-convex structure core and gradient surface and its preparation method

A composite foaming, concave-convex structure technology, applied in chemical instruments and methods, fiber processing, fiber types, etc., can solve the problems of reducing the bending and tensile strength of composite materials, obvious nucleation of additives, and destroying cell morphology, etc. Achieve the effect of improving application performance, increasing functional processing selectivity, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

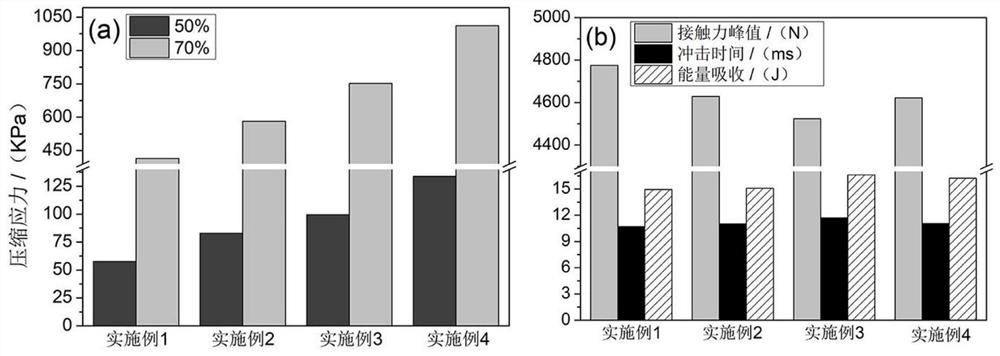

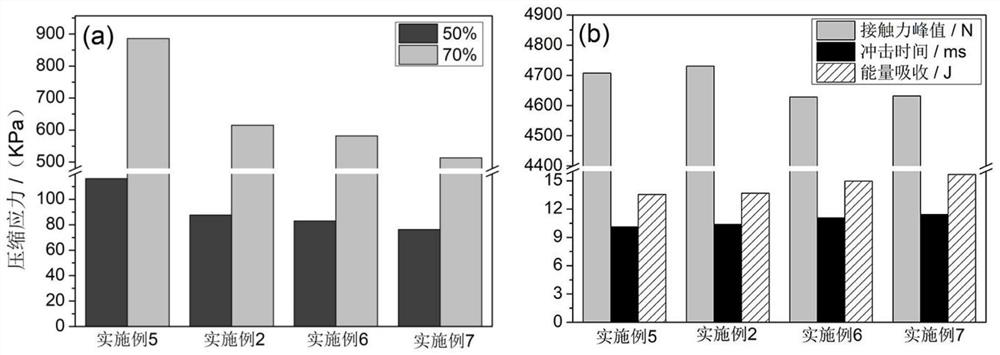

Examples

Embodiment 1~7

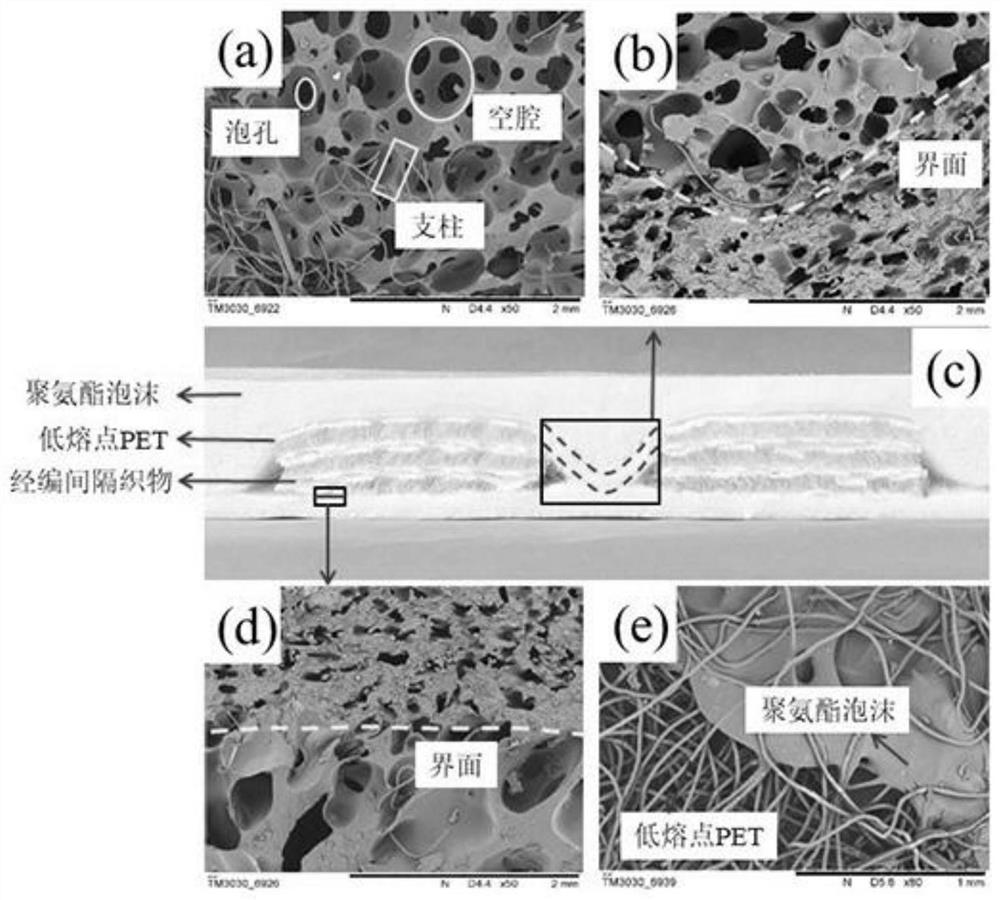

[0037] A method for preparing a three-dimensional flexible composite foam material with a concave-convex structure core and a gradient surface, comprising the following steps:

[0038] Step 1, prepare a plurality of identical rectangular parallelepiped warp-knitted spacers, the preparation method of each rectangular parallelepiped warp-knitted spacer is: prepare a plurality of identical square warp-knitted spacers, carry out a plurality of warp-knitted spacers along its thickness direction Bonding to obtain a cuboid warp-knitted spacer fabric, using hot melt adhesive for bonding; wherein, the thickness of the warp-knitted spacer fabric is 3.3 mm, and the mesh size is 4 mm. The side length of the spacer fabric is X mm. The thickness of the cuboid warp-knitted spacer fabric is 9.9mm.

[0039] Step 2, prepare 2 identical PET nonwoven fabrics: the first PET nonwoven fabric and the second PET nonwoven fabric, and arrange a plurality of rectangular parallelepiped warp-knitted space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com