Roadbed slope protection structure, and manufacturing method and application thereof

A technology of slope protection and production methods, which is applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of expensive labor input, heavy-duty operations of operators, and slow construction progress, so as to achieve fast operation, cost-saving finished products, and construction less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

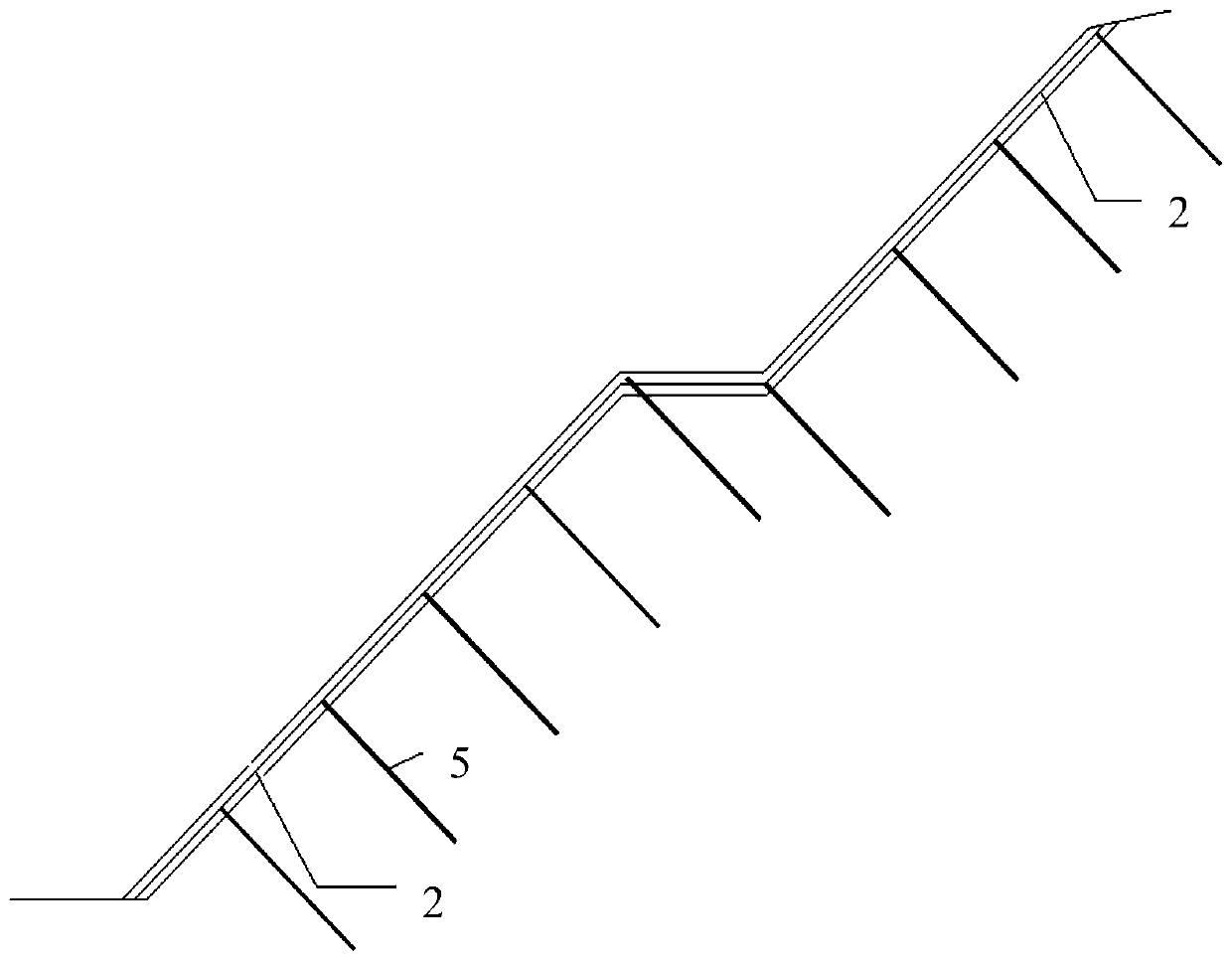

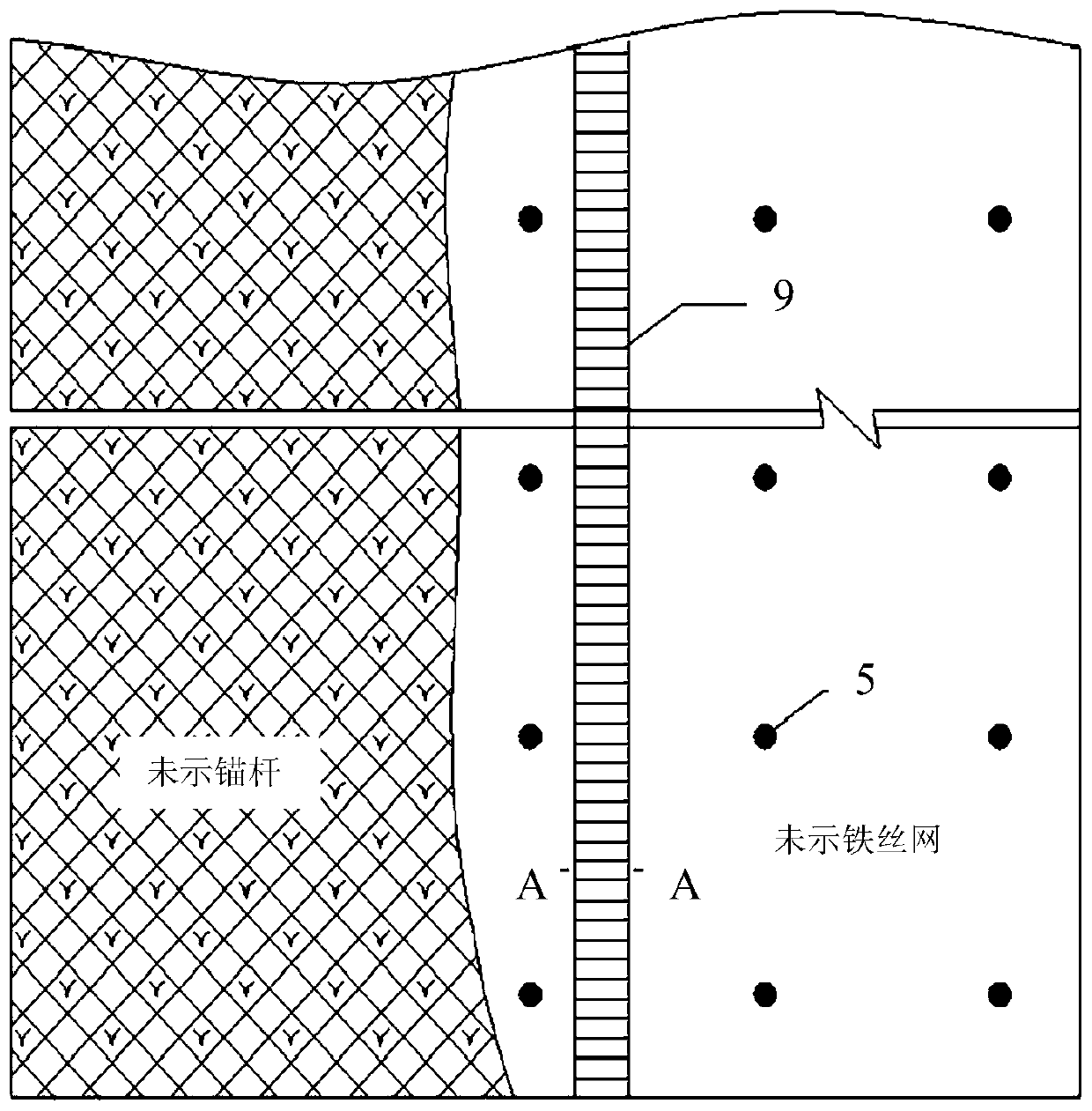

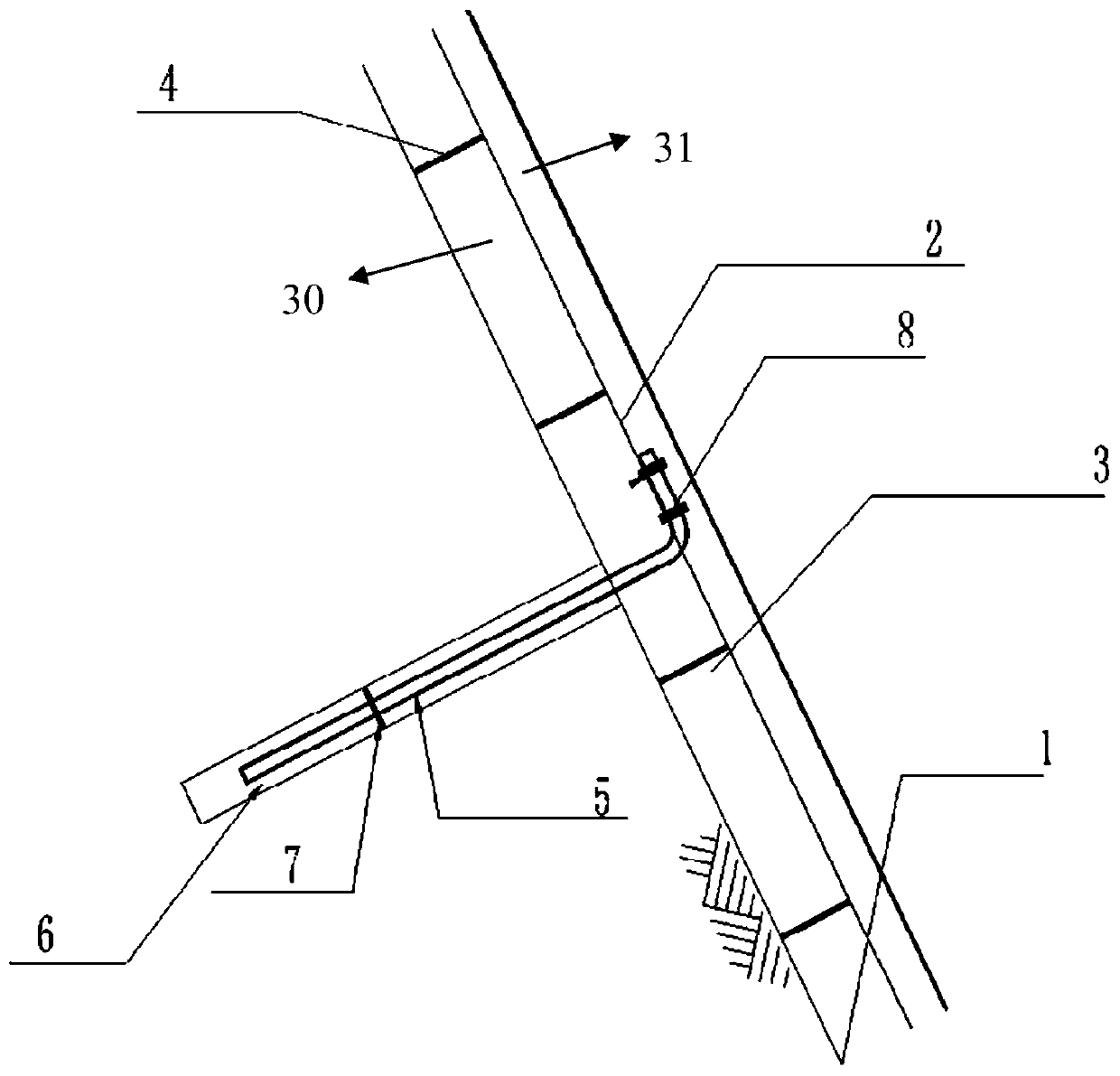

[0079] This embodiment provides a roadbed slope protection structure, wherein, the schematic diagram of the roadbed slope protection structure is as follows figure 2 and image 3 shown, from figure 2 and image 3 It can be seen that it includes coconut fiber blanket 1, barbed wire 2, mixed base material 3 and several anchor rods 5;

[0080] The coconut fiber blanket is used to be fixed on the roadbed slope, and a planting board 4 is arranged between the coconut fiber blanket and the wire mesh, for supporting the wire mesh and making the wire mesh spaced from the coconut fiber blanket preset distance;

[0081] A plurality of anchor rods can be distributed on the roadbed slope at intervals, and the first end of the anchor rod is inserted into the roadbed slope anchor hole 6 (with a diameter of 5 cm) along the direction perpendicular to the roadbed slope , the distance between the first end of the anchor rod and the bottom of the embankment slope anchor hole is 10cm, and th...

Embodiment 2

[0096] This embodiment provides a high liquid limit soil subgrade slope protection treatment process, wherein the high liquid limit soil subgrade slope protection treatment process uses the subgrade slope protection structure provided in Example 1, and the process includes the following specific steps :

[0097] Fabrication of roadbed slope protection structure:

[0098] Step 1. High liquid limit soil subgrade slope leveling: leveling the slope to be constructed before construction to remove protruding stones and other sundries;

[0099] Step 2. Coconut fiber blanket laying: start from the landfill layer at the top of the slope and spread it smoothly from top to bottom. Use U-shaped rivets to fix the coconut fiber blanket on the slope at the top of the slope, and sew and splice the joints at the head and tail. Or overlap 4cm-8cm and fix it with rivets. The newly laid coconut fiber blanket should be placed underneath when lapping. The rivets used for lapping and fixing are U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com