Nonmagnetic bearing, centerless fixture and nonmagnetic bearing manufacturing method

A centerless fixture and manufacturing method technology, applied in the field of bearings, can solve the problems of wireless charging rotor vibration and noise, poor structural design and manufacturing quality, etc., and achieve the effects of satisfying processing design requirements, improving running trajectory, and improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

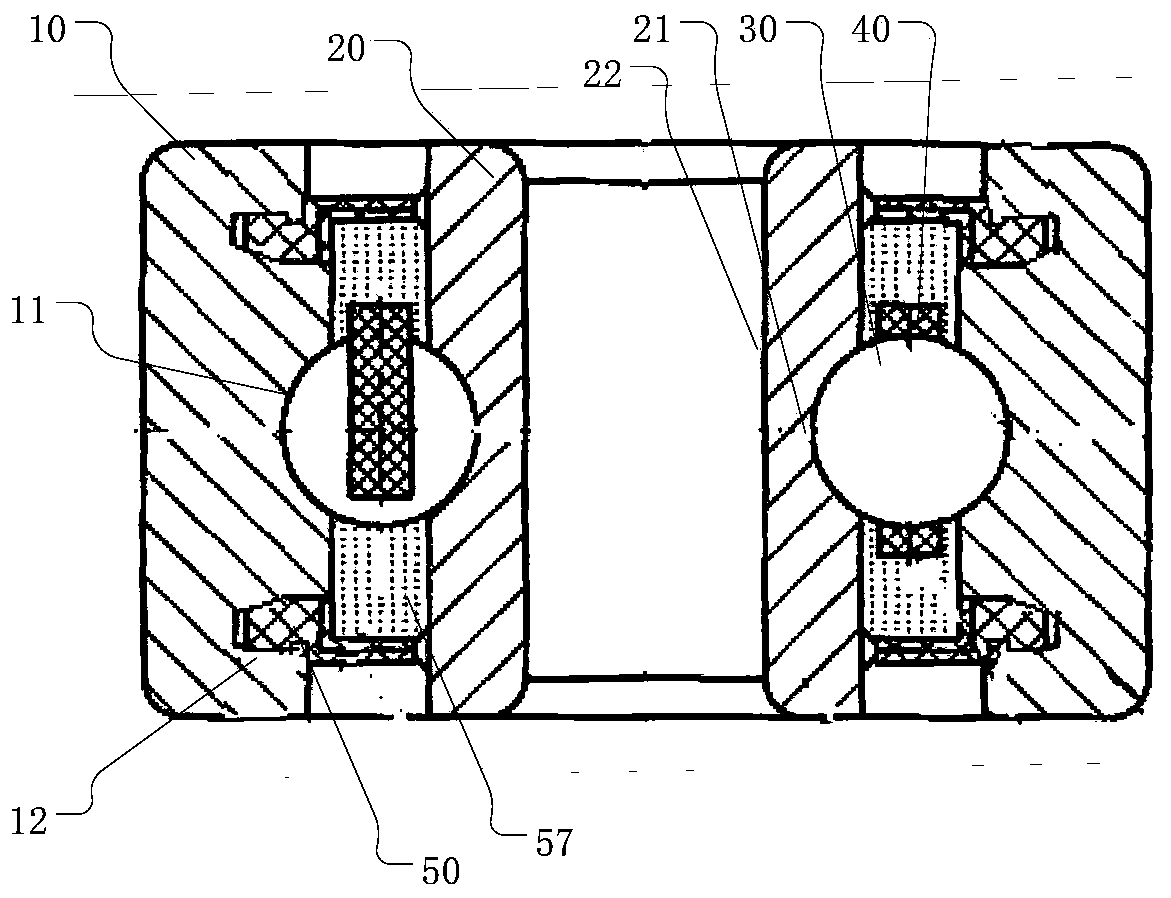

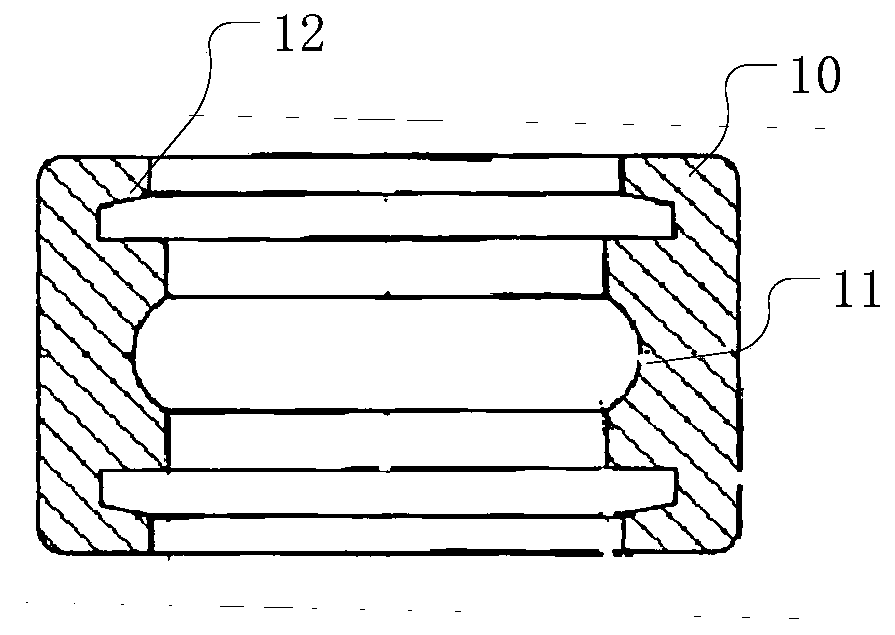

[0058] The embodiment of the present invention provides a non-magnetic bearing, which is made of non-magnetic materials, such as figure 1 As shown, it includes: an outer ring 10 , an inner ring 20 , a cage 40 and ceramic balls 30 .

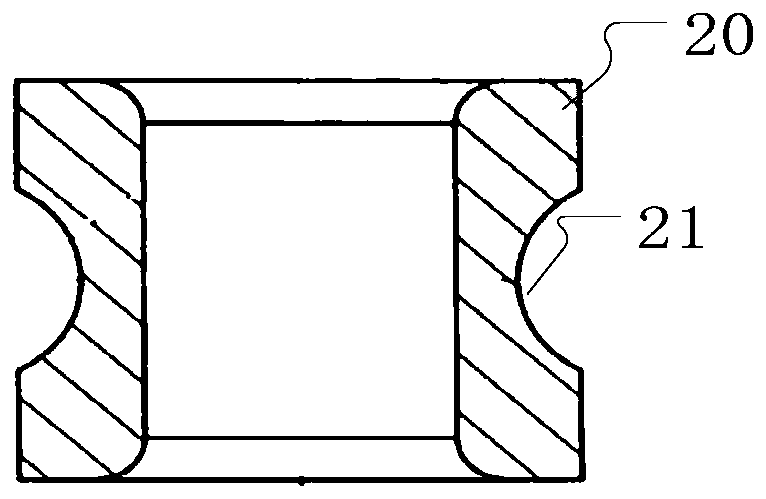

[0059] A first groove 11 is provided in the circumferential direction of the center of the inner diameter of the outer ring 10 , and a second groove 21 matching the first groove 11 is provided in the circumferential direction of the center of the outer diameter of the inner ring 20 . It should be noted that, here, the center of the inner diameter of the outer ring 10 refers to the center of the inner diameter surface, and the center of the outer diameter of the inner ring 20 refers to the center of the outer diameter surface. Specifically, such as Figure 2-3 As shown, the outer ring 10 and the inner ring 20 are made of non-magnetic materials, such as Fe—Mn—Cr—C series austenitic stainless steel materials. Optionally, the outer ring 10 and the i...

Embodiment 2

[0066] This embodiment provides a non-magnetic bearing, which includes, in addition to the non-magnetic bearing provided in Embodiment 1, seal rings 50 disposed between the inner ring 20 and the outer ring 10 and on both sides of the ceramic ball 30 .

[0067] There are two sealing rings 50, and grease 57 is filled in the space surrounded by the two sealing rings 50, the inner ring 20 and the outer ring 10, thereby improving the life of the bearing and preventing the rotor from vibrating under high-speed rotation. Specifically, such as figure 1 with Image 6 As shown, the sealing ring 50 can be made of nitrile rubber, butyl rubber or EPDM rubber. Optionally, the sealing ring 50 is made of EPDM. The outer diameter surface 55 of the sealing ring 50 is provided with a flexible lip 51 , and the inner diameter surface 56 of the sealing ring 50 is in clearance fit with the outer diameter of the inner ring 20 . The inner diameter of the outer ring 10 is circumferentially provided...

Embodiment 3

[0074] The groove processing of conventional bearing steel outer ring or inner ring is to fix the outer ring or inner ring on the rotating positioning ring 91 of the machine tool by electromagnetic fixture, and then use the grinding wheel 92 for grinding. However, since the outer ring 10 and the inner ring 20 are made of non-magnetic materials, an electromagnetic chuck cannot be used. At the same time, because the spring chuck is affected by the radial runout of the main shaft 93, it is difficult to ensure the machining accuracy of the first groove 11 of the outer ring 10, the second groove 21 of the inner ring, and the inner diameter of the inner ring during the grinding process. As a result, the manufacturing quality of the non-magnetic bearing is poor, and the quality requirements of the non-magnetic bearing cannot be met.

[0075] After repeated research, the embodiment of the present invention also designs and manufactures a centerless clamp, which is used to fix the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic permeability | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com