Split type mechanical variable speed equipment with automatic lubricating function

A technology of automatic lubrication and mechanical speed change, applied in mechanical equipment, gear lubrication/cooling, transmission parts, etc., can solve the problems of increasing equipment cost and maintenance cost, heavy maintenance work by users, time-consuming and laborious disassembly process, etc. To achieve the effect of simple structure, convenient replacement and maintenance, and reduction of mechanical friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

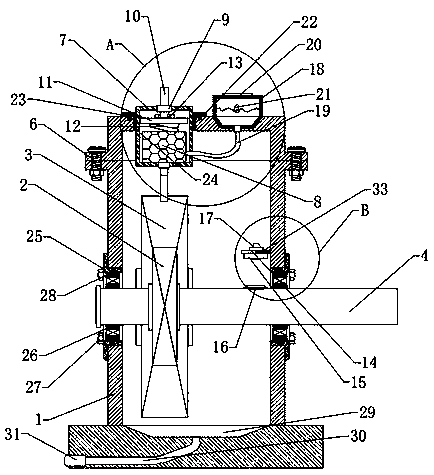

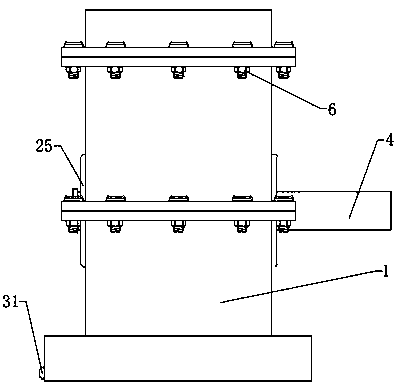

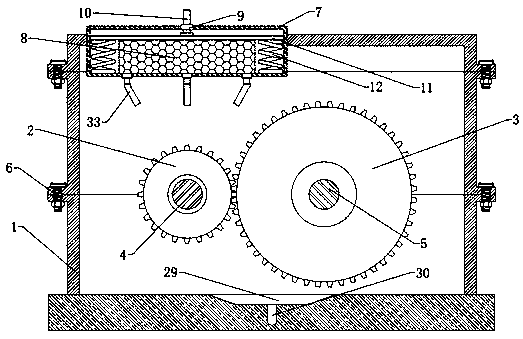

[0041] Embodiment: according to specification Figure 1-10 It can be seen that this case is a split-type mechanical transmission device with automatic lubrication function, which mainly includes a housing 1, a driving gear 2, a driven gear 3, a driving shaft 4, a driven shaft 5, several threaded components 6 with the same structure, and a mechanical The lubricating mechanism, two pairs of drag-reducing structures with the same structure, and the leaking liquid outlet structure, their connection relationship and positional relationship are as follows;

[0042] The housing 1 is a steel cavity housing 1 with a rectangular structure. A pair of first through holes with the same structure are opened on both side walls of the housing 1. The driving shaft 4 is movably installed in the pair of first through holes. The driving gear 2 Sleeved on the driving shaft 4, a pair of second through holes with the same structure are opened on both side walls of the housing 1 and on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com