Heat exchanger and draught fan

A heat exchanger and heat exchange medium technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve problems such as difficult breakthroughs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to enable those skilled in the art to better understand the technical solutions of the embodiments of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0068] The inventors of the present application aimed at the current situation that the heat exchange effect of plate-fin heat exchangers is difficult to break through. From the perspective of combining fluid mechanics and heat transfer, the inventors of the present application found another way to find an optimized way. Therefore, before discussing specific embodiments, first describe The inventors of the present application explored the process of other possible factors affecting the efficiency of plate-fin heat exchangers.

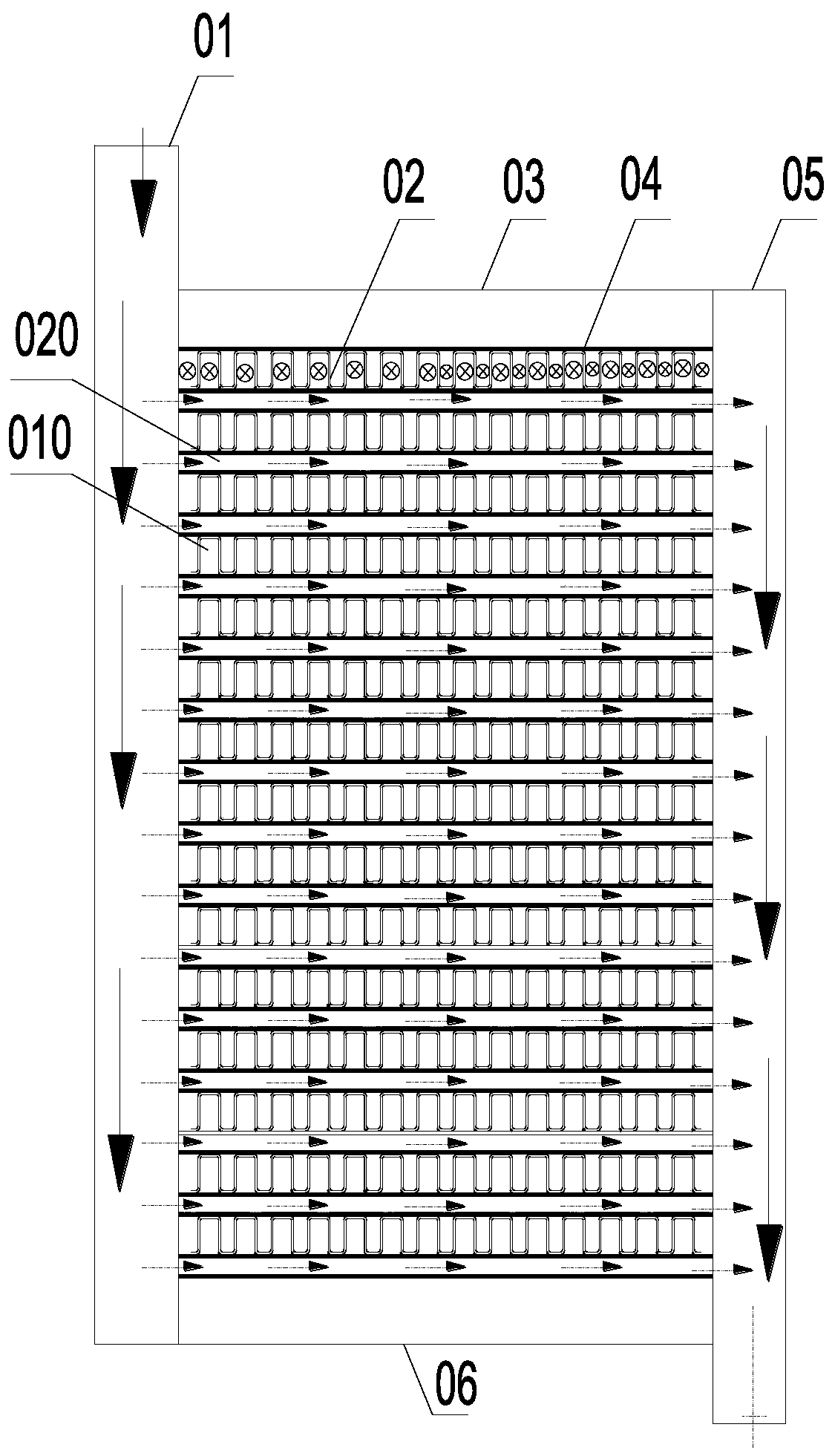

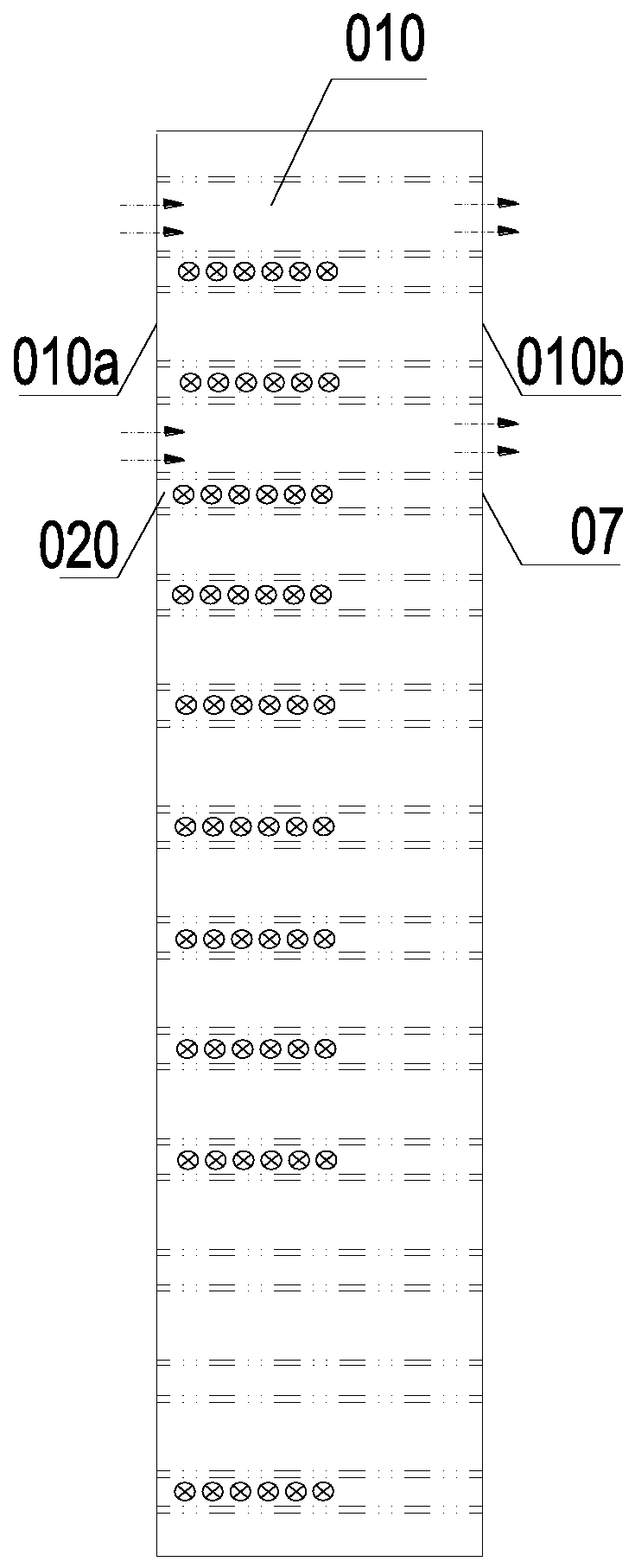

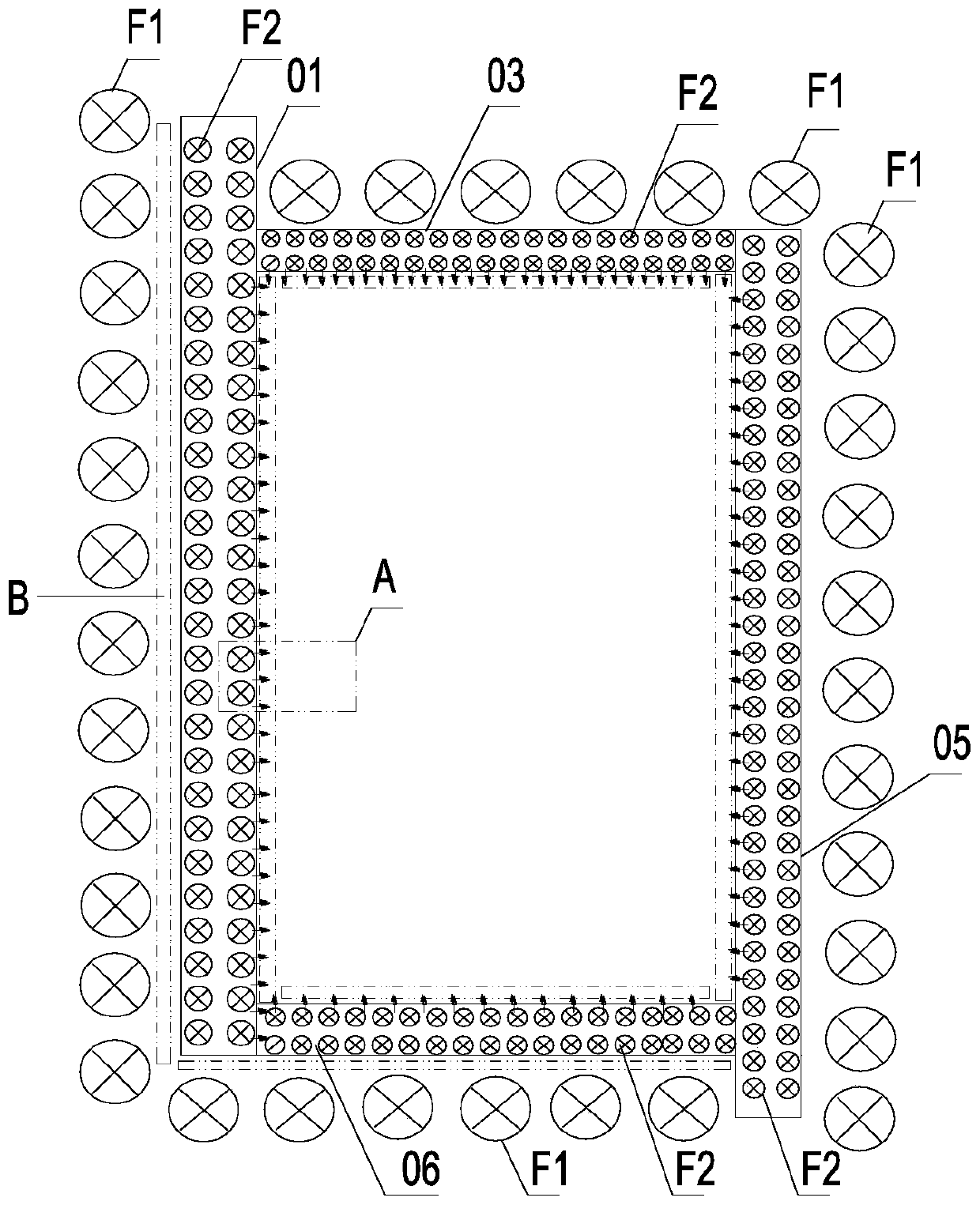

[0069] Please continue to view image 3 , image 3 head on for air figure 1 A schematic diagram of a support frame of a plate-fin heat exchanger, the support frame includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com