Electric integrated operating device for J-shaped wire clamp

An operating device and wire clip technology, which is applied to the coupling device, the parts of the connecting device, and the connection/disconnection of the connecting device, etc., can solve the problems of danger, unstable clamping force of the operating device, cumbersome operation process, etc. The effect of simplicity, shortening work time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

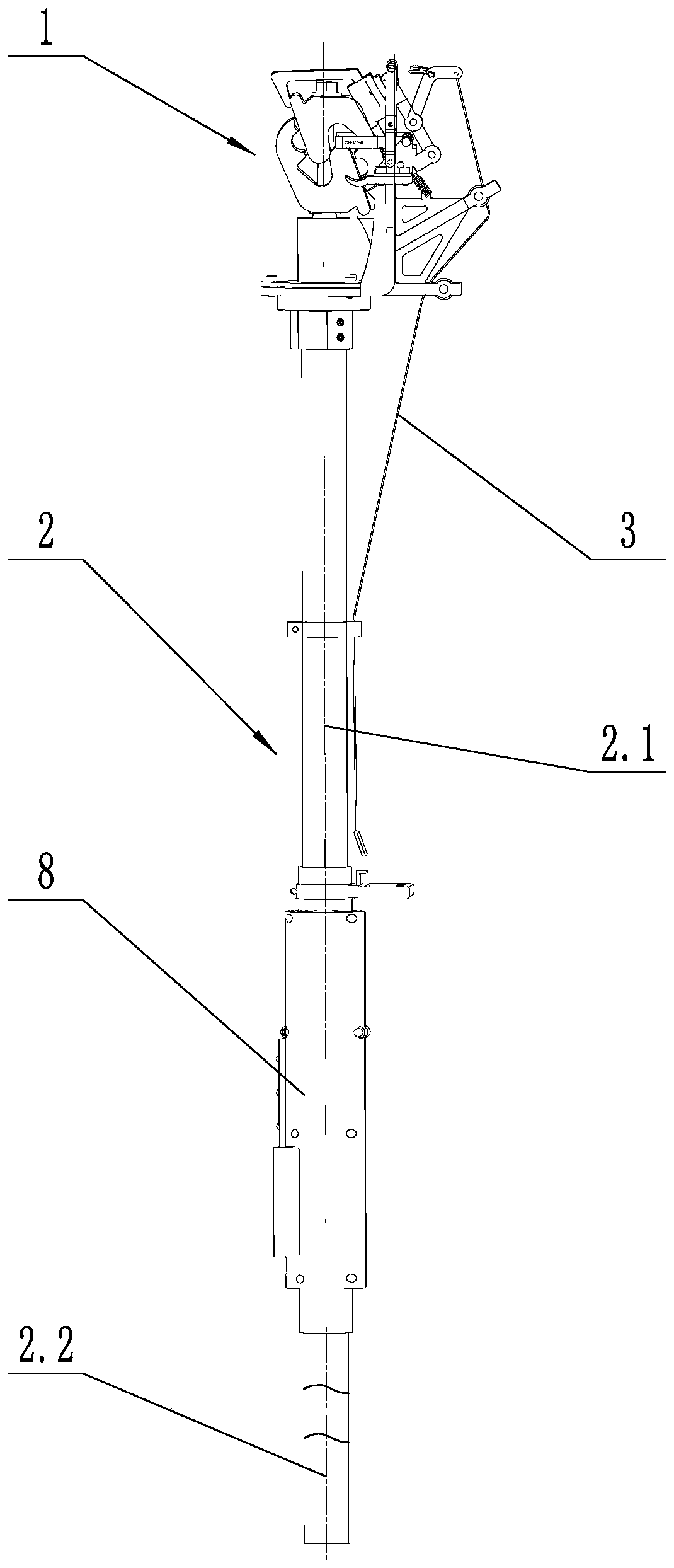

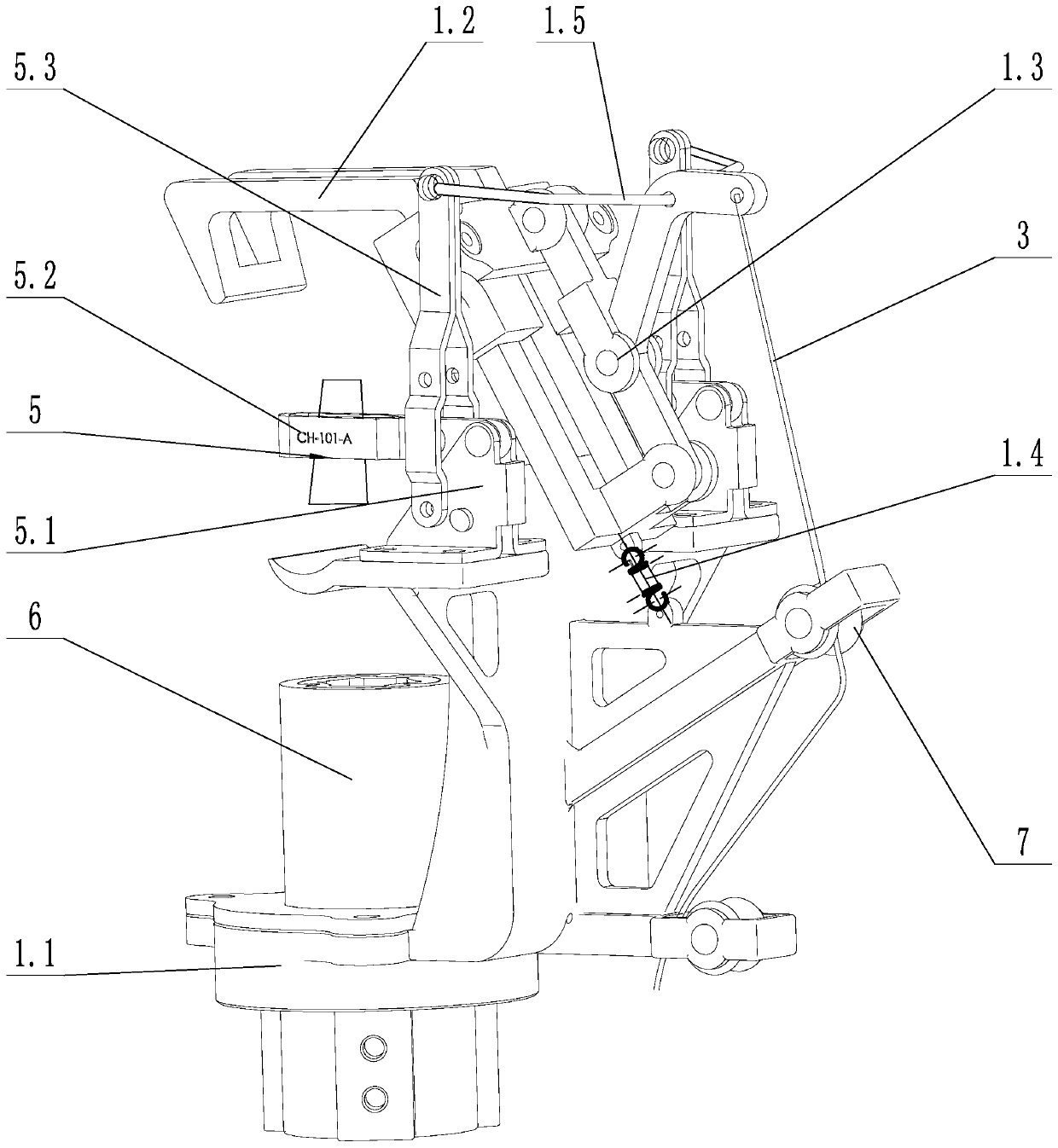

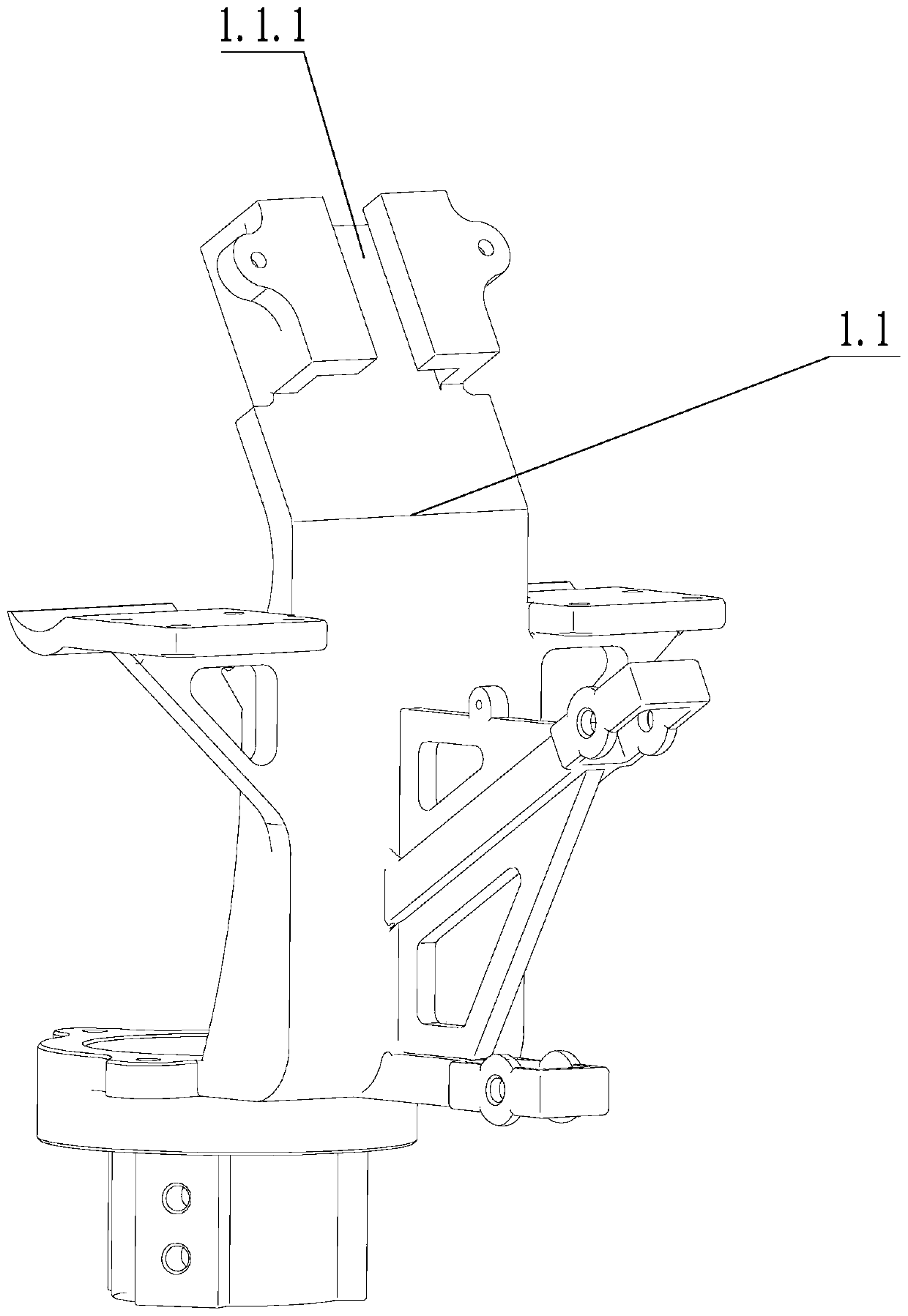

[0032] Such as figure 1 As shown, a J-type wire clamp electric integrated operating device includes a clamping assembly 1 and an insulating rod 2; as figure 2 , image 3 with Figure 4 As shown, the clamping assembly 1 includes a main frame 1.1, a slide bar chuck 1.2 for clamping a J-shaped clamp, a linkage mechanism 1.3 and a first telescopic spring 1.4, and the main frame 1.1 is provided with a chute 1.1.1, The guide wheel 7 and the nut fastening device 6, the slide bar chuck 1.2 includes a slide bar part 1.2.1 and a chuck part 1.2.2, and the slide bar part 1.2.1 is adapted and slidably connected to the chute 1.1.1; the first One end of the telescopic spring 1.4 is connected with the main body frame 1.1, and the other end of the first telescopic spring 1.4 is connected with the slider chuck 1.2; the link mechanism 1.3 includes a first connecting rod 1.3.1 and a second connecting rod 1.3. The lever 1.3.2 includes a locking lever 1.3.2.1 and an unlocking lever 1.3.2.2 conn...

Embodiment 2

[0037] Such as figure 2 As shown, on the basis of implementation 1, the main frame 1.1 is provided with a quick wire clamp 5, and the quick wire clamp 5 includes a base 5.1, a clamping piece 5.2 and a locking piece 5.3 for locking the clamping piece 5.2; The base 5.1 is arranged on both sides of the slider clamp 1.2, one end of the locking piece 5.3 is hinged with the base 5.1, the other end of the locking piece 5.3 is connected with the unlocking lever 1.3.2.2 through the connecting piece 1.5, and the locking piece 5.3 The direction of rotation is parallel to the direction of rotation of the locking lever 1.3.2.1. .

[0038] The above connecting piece 1.5 is indirectly fixed to the main frame 1.1 by connecting with the quick wire clamp 5. When the clamping piece 5.2 clamps the cable together with the main frame 1.1, the locking piece 5.35..3 is far away from the unlocking lever 1.3.2.2, At this time, the unlocking pull cord 3 is pulled, and the unlocking lever 1.3.2.2 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com