Geopolymer-containing cement paste-based grouting material suitable for high-ground-temperature environment and preparation method thereof

A geopolymer and grouting material technology, which is applied in the field of geopolymer-containing cement slurry-based grouting materials and its preparation in high ground temperature environments, can solve the impact of grouting stones on mechanical properties and durability, chemical grout is toxic and harmful, Deteriorating the construction work environment and other problems, achieving the effect of reducing urban environmental pollution, promoting rapid precipitation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high ground temperature environment containing geopolymer cement slurry-based grouting material provided in this embodiment is specifically: take 1000ml of water, 960g of cement, 40g of metakaolin and 1.2g of sodium hydroxide, and mix ordinary silicate Pour the cement and metakaolin into the powder mixer and stir for 5-15 minutes to ensure uniform mixing.

[0033] Pour sodium hydroxide into water, stir well, stand still for 12 hours, stir again, and add mixed ordinary Portland cement and metakaolin, after stirring for 5 minutes, stop stirring for 2 minutes, and then stir for 5 minutes to make grouting material.

Embodiment 2

[0035] A kind of geopolymer-containing cement slurry-based grouting material provided in this embodiment is specifically: take 1000ml of water, 920g of ordinary Portland cement, 80g of metakaolin and 1.2g of sodium hydroxide, and Ordinary Portland cement and metakaolin are poured into the powder mixer and stirred for 5-15 minutes to ensure uniform mixing.

[0036] Pour sodium hydroxide into water, stir well, stand still for 12 hours, stir again, and add mixed ordinary Portland cement and metakaolin, after stirring for 5 minutes, stop stirring for 2 minutes, and then stir for 5 minutes to make grouting material.

Embodiment 3

[0038] A high ground temperature environment containing geopolymer cement slurry-based grouting material provided in this embodiment is specifically: take 1000ml of water, 880g of cement, 120g of metakaolin and 1.2g of sodium hydroxide, and mix ordinary silicate Pour the cement and metakaolin into the powder mixer and stir for 5-15 minutes to ensure uniform mixing.

[0039] Pour sodium hydroxide into water, stir well, stand still for 12 hours, stir again, and add mixed ordinary Portland cement and metakaolin, after stirring for 5 minutes, stop stirring for 2 minutes, and then stir for 5 minutes to make grouting material.

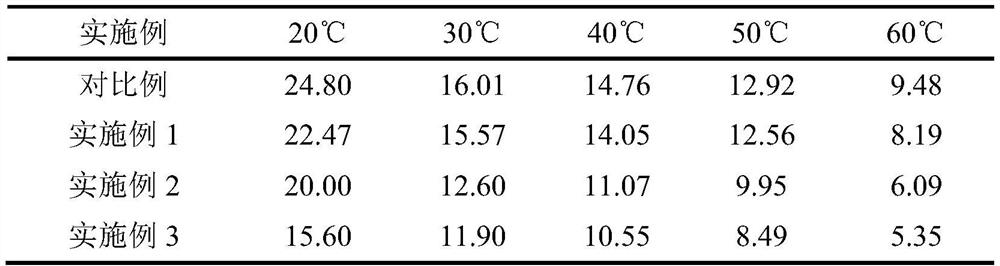

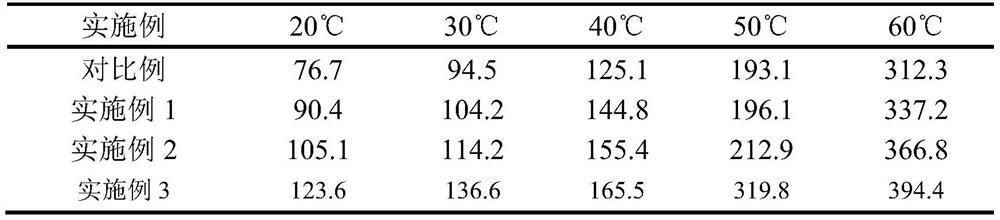

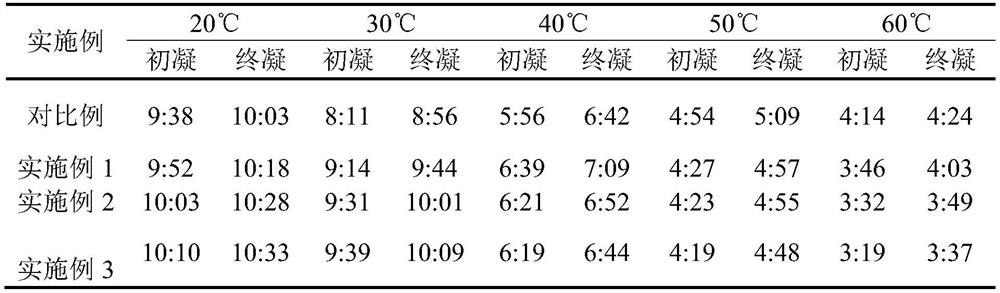

[0040] For verifying the characteristics of the grouting material prepared in the present invention, carry out following test, in following test, slurry refers to the grouting material that comparative example and each embodiment prepare, concrete test is as follows:

[0041] 1. Determination of slurry stability - water separation rate test:

[0042] Pour t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com