Axial magnetic field reverse salient pole permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and axial magnetic field, which is applied to synchronous motors with stationary armatures and rotating magnets, motors, magnetic circuits, etc., can solve problems such as increasing inverter capacity and reducing drive system efficiency The effect of high power density and reliability, high structural strength and small cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

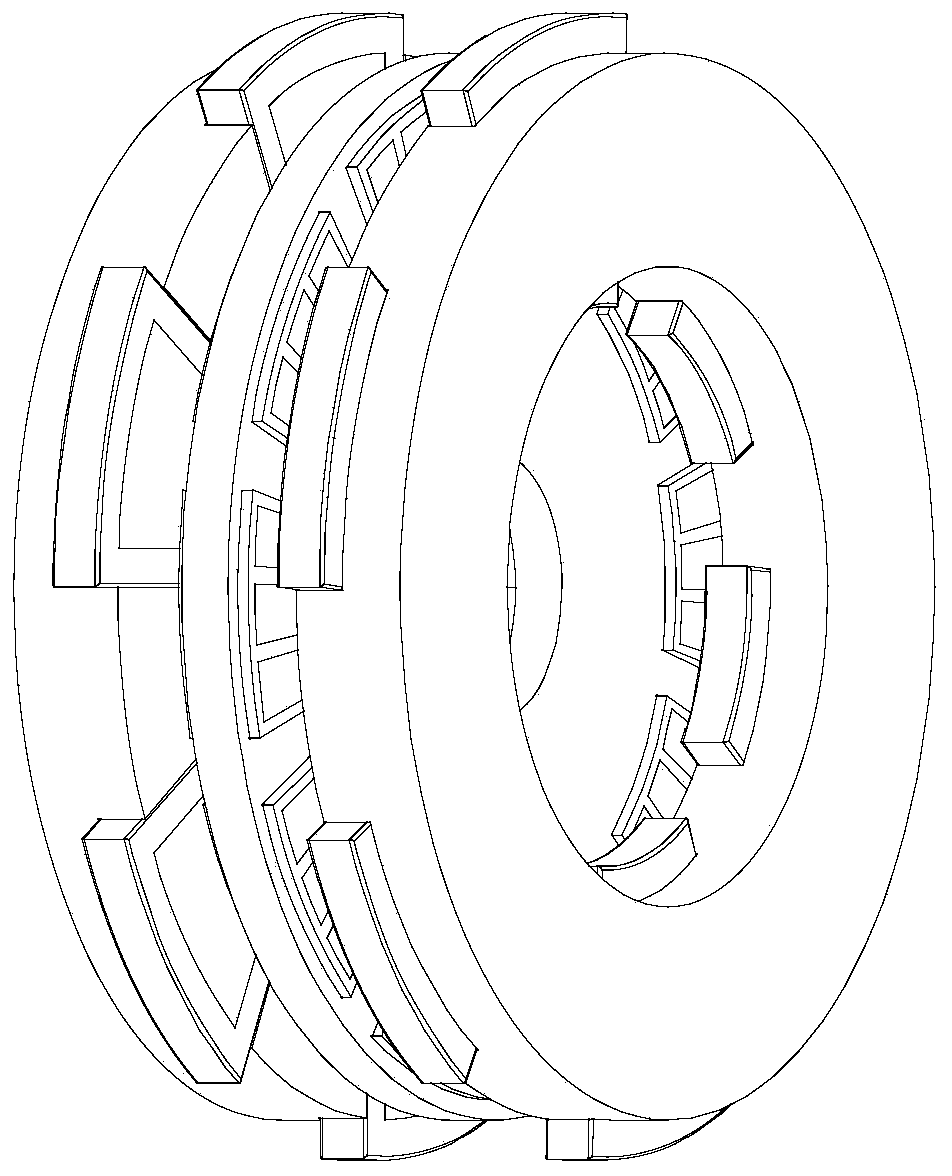

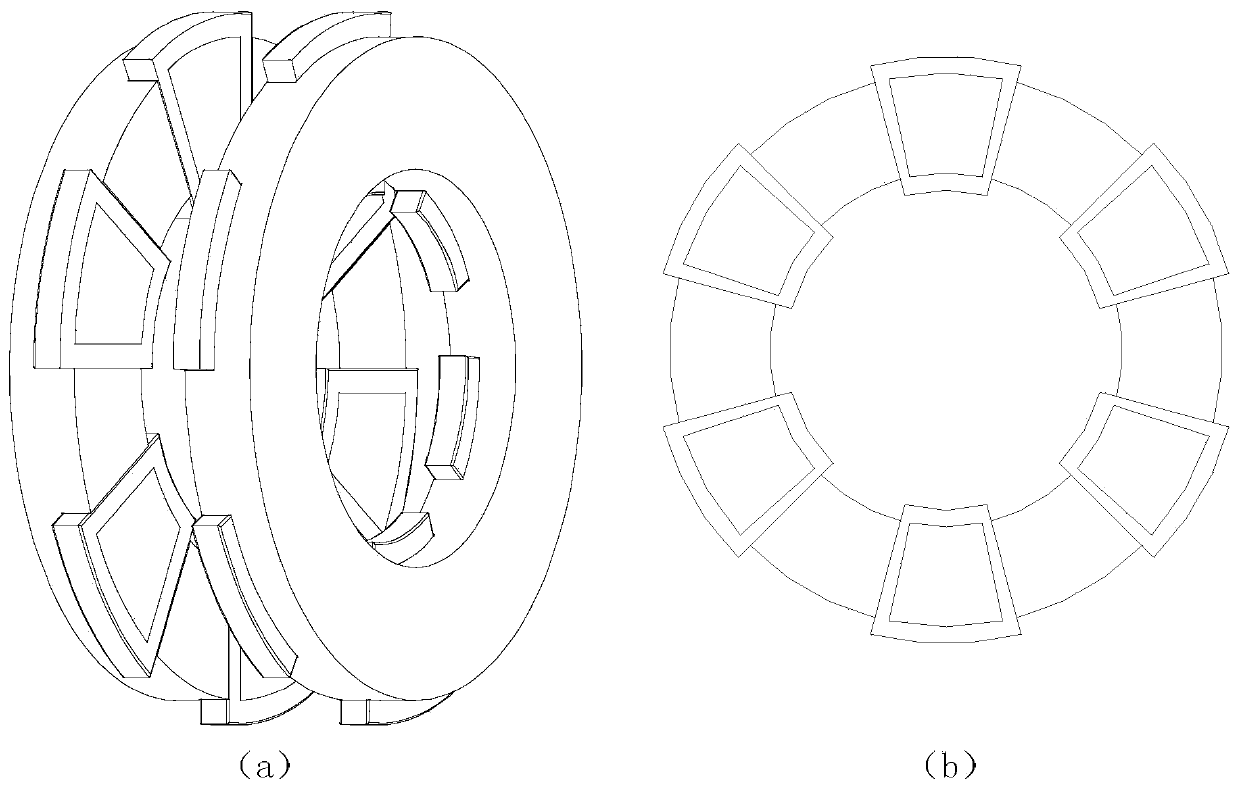

[0057] Specific implementation mode one: refer to Figure 5 , 6 , 7, 9 and 10 specifically describe this embodiment, the axial magnetic field anti-salient pole permanent magnet synchronous motor described in this embodiment includes: a rotor and two stators, the rotor and the two stators are coaxially arranged, and the rotor is located at two There is an air gap between the two stators, and between the rotor and the two stators.

[0058] The rotor includes a circular base plate, on which there are 2p circular sector-shaped magnetic pole unit embedding through holes uniformly arranged along its circumference, and the narrow sides of the ring sector are all facing the center of the base plate, and each magnetic pole A magnetic pole unit is embedded inside the unit embedding through hole,

[0059] The magnetic pole unit includes a magnetizer and 2k+1 permanent magnets, the outer contour of the magnetizer is the same as the inner contour of the through hole for embedding the mag...

specific Embodiment approach 2

[0061] Specific implementation mode two: refer to Figure 5 , 6 , 7, 8 and 10 specifically illustrate this embodiment, the axial magnetic field anti-salient pole permanent magnet synchronous motor described in this embodiment includes: a rotor and two stators, the rotor and the two stators are coaxially arranged, and the rotor is located at two There is an air gap between the two stators, and between the rotor and the two stators.

[0062] The rotor includes a circular base plate, on which there are 2p circular sector-shaped magnetic pole unit embedding through holes uniformly arranged along its circumference, and the narrow sides of the ring sector are all facing the center of the base plate, and each magnetic pole A magnetic pole unit is embedded inside the unit embedding through hole,

[0063] The magnetic pole unit includes a magnetizer and 2n pieces of permanent magnets. The outer contour of the magnetizer is the same as the inner contour of the through hole for embeddi...

specific Embodiment approach 3

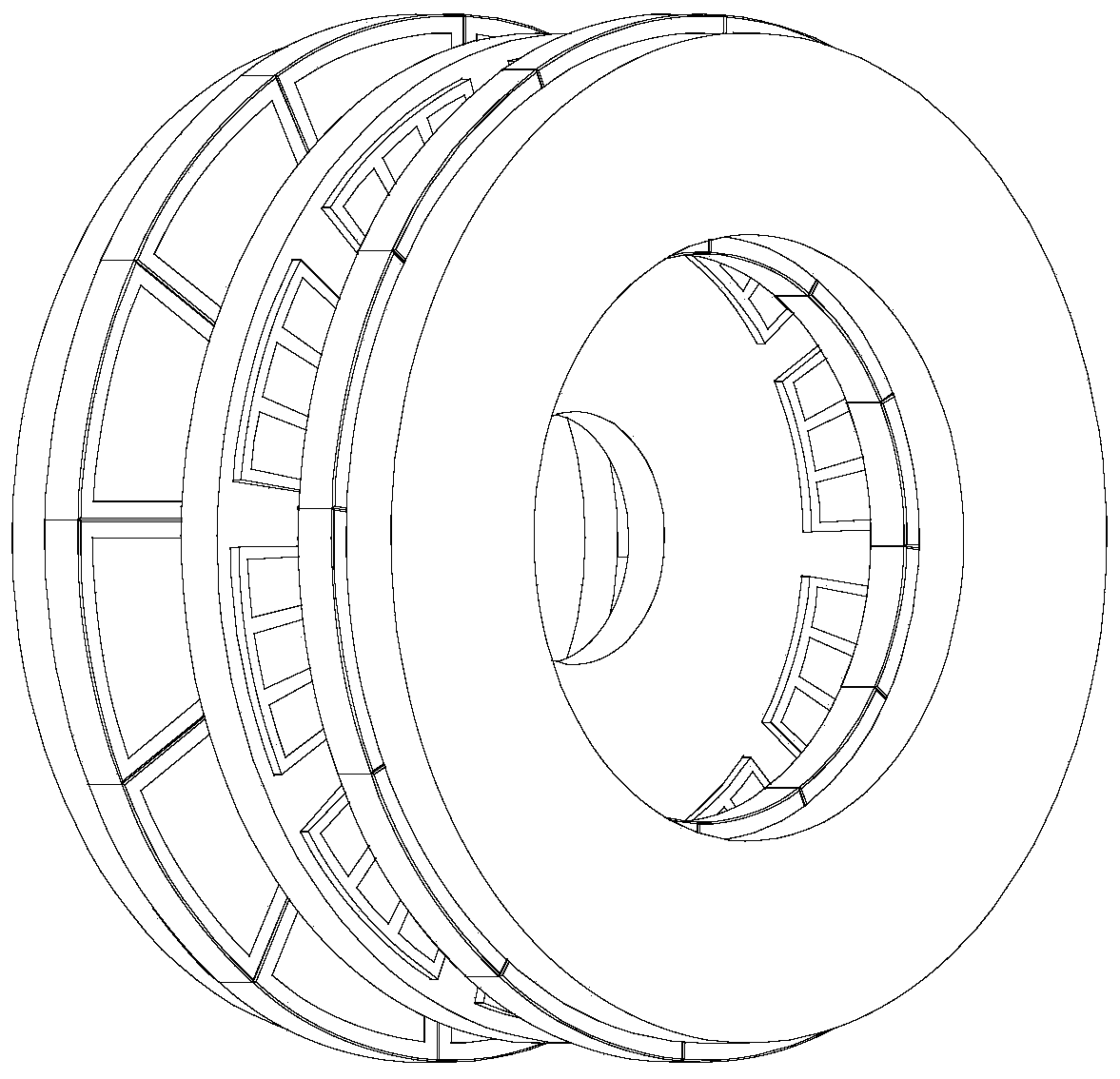

[0065] Specific implementation mode three: refer to Figure 7 , 9 , 10, 11 and 12 specifically describe this embodiment, the axial magnetic field anti-salient pole permanent magnet synchronous motor described in this embodiment includes: a rotor and two stators, the rotor and the two stators are coaxially arranged, and the rotor is located at two There is an air gap between the two stators, and between the rotor and the two stators.

[0066] The rotor includes a ring-shaped base plate, and 2p grooves are evenly opened on the circumference of the base plate to the direction of its inner ring, and each groove is embedded with a magnetic pole unit.

[0067] The magnetic pole unit includes a magnet guide and 2k+1 permanent magnets, the magnet guide is in the shape of a ring sector, and the magnet guide is evenly opened with 2k+1 permanent magnet embedding holes along its circumference, and the 2k+1 permanent magnets are respectively embedded in the 2k+1 permanent magnets are emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com