Separation system for tunnel sewage treatment and construction method thereof

A technology of sewage treatment and separation system, which is applied in the field of separation system of sewage treatment in tunnels, which can solve problems such as difficulty in slag discharge, achieve the effects of improving construction efficiency, ensuring construction progress, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0048] The specific embodiment of the separation system that the present invention is used for tunnel sewage treatment is as follows:

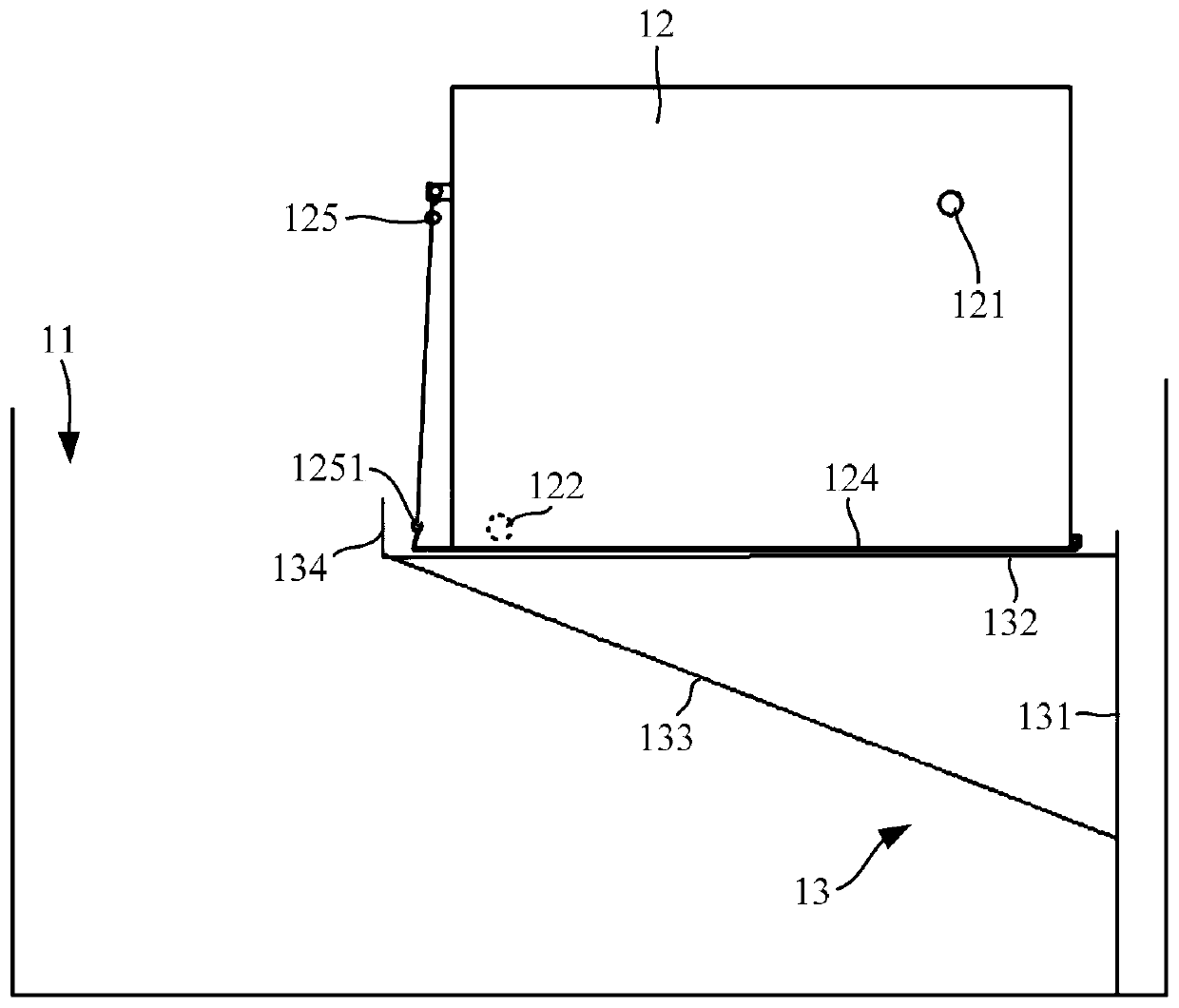

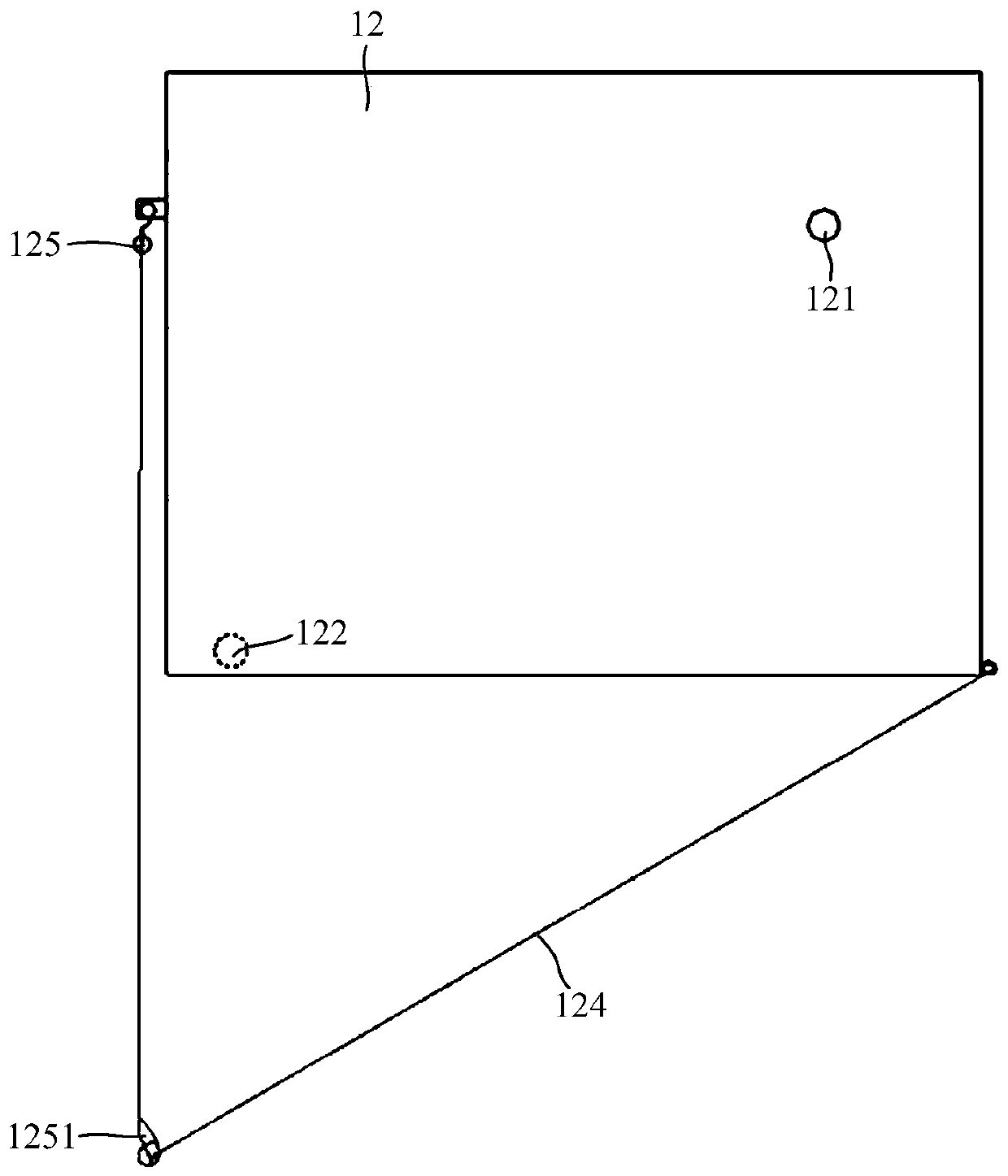

[0049] Excavate the dregs pool 11 at a position close to the tunnel, install a bracket 13 in the dregs pool 11, and install the box body 12 on the bracket 13;

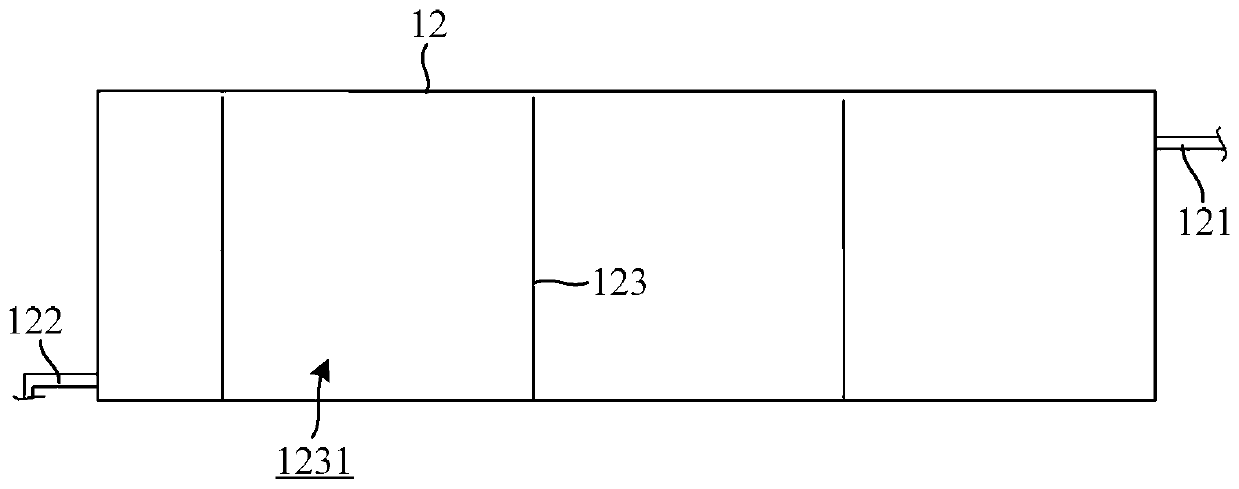

[0050] The sewage in the tunnel is driven into the sewage pipe through the pump body, and enters the corresponding sedimentation space 1231 through the feed port 121, and flows into the adjacent sedimentation space 1231 through the flow holes on the partition plate 123, and passes through several sedimentation spaces 1231 After the graded sedimentation, it flows into the sedimentation space 1231 of the final stage, and at this time, the sedimentation space 1231 is the supernatant liquid separated from the sewage;

[0051] The supernatant in the final settling space 1231 is discharged from the outlet pipe to the waterway through the outlet 122, and the hoisting device 125 is operated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com