Anti-sticking agent smearing device of road roller

A technology of anti-sticking agent and road roller, which is applied to the device for coating liquid on the surface, spray device, coating and other directions, can solve the problems of high energy consumption and insufficient economy, and achieve energy saving, convenient maintenance and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

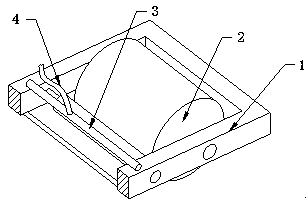

Image

Examples

specific Embodiment approach

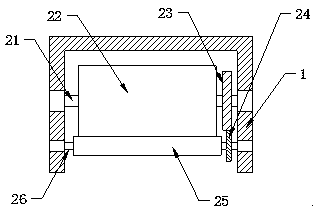

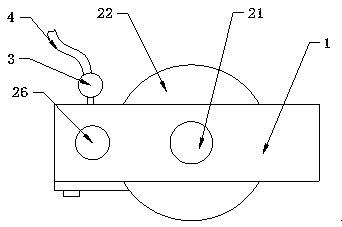

[0020] Specific embodiments: In order to achieve the purpose of road rolling, the frame 1 is fixedly connected with the road roller, and the pressure roller 22 is always in contact with the asphalt ground. Therefore, when the road roller is walking, the pressure roller 22 is driven by the frame 1 to roll along the road surface, so that the pressure roller 22 drives the shaft One 21 rotates around the two sets of sleeves. The rotation of shaft one 21 drives the rotation of gear one 23. Since gear one 23 is engaged with gear two 24, the rotation of gear one 23 drives gear two 24 to rotate, and the rotation of gear two 24 drives shaft two 26. It rotates around the two sets of shaft sleeves, and at the same time, the second rotating shaft 26 drives the application roller 25 to rotate. Then when the diesel in the fuel supply pipeline flows into the fuel injection pipe 3 through the fuel delivery pipe 4, the diesel fuel is injected through the fuel injection hole on the fuel injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com