Rubber breaker

A crusher and plastic technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve problems such as crushing blockage, affecting equipment life, adhesion, etc., to prevent blockage and jamming, to meet the needs of recycling production, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

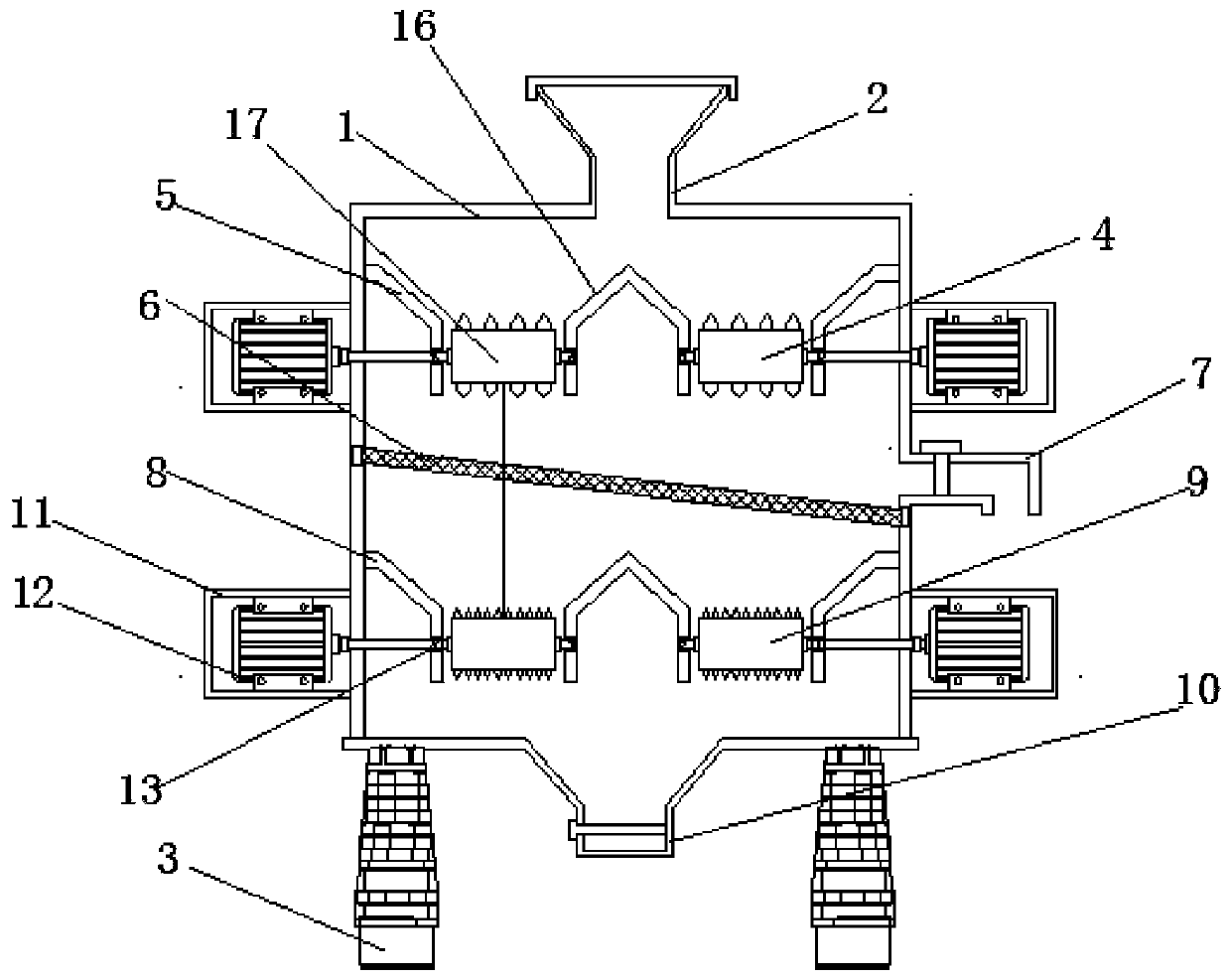

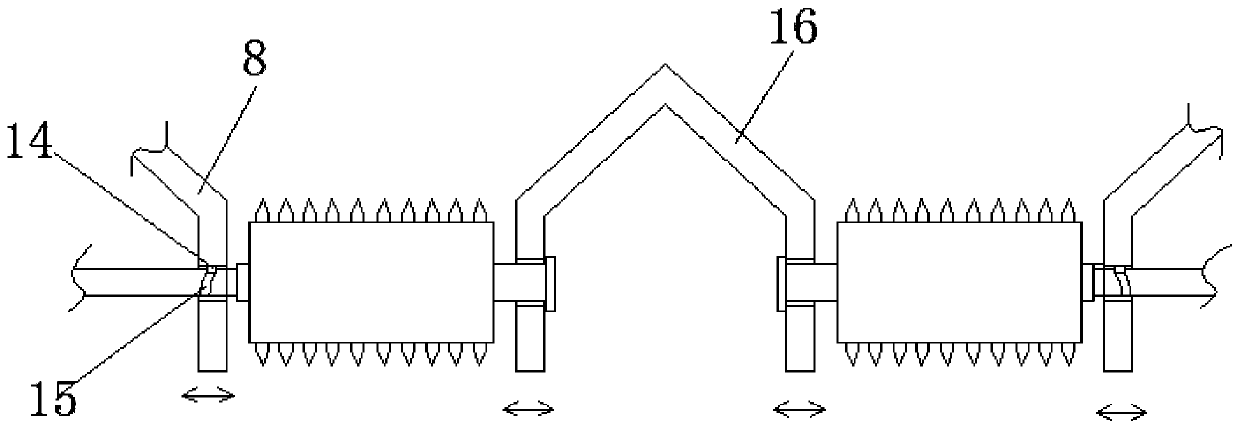

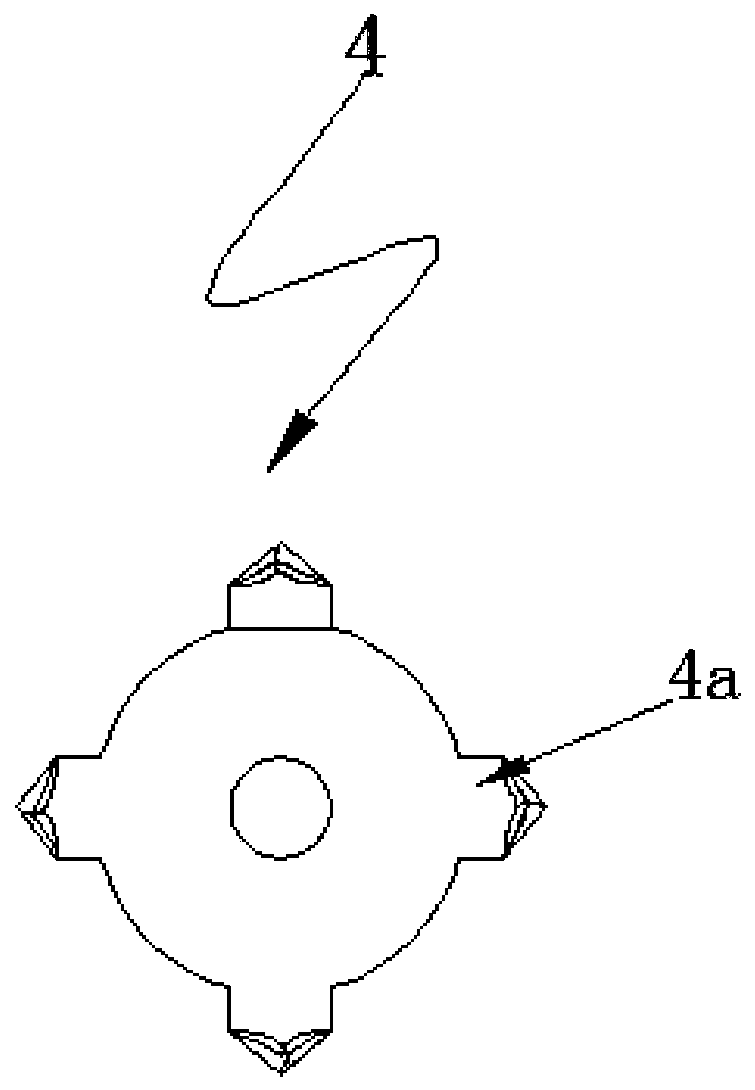

[0033] see Figure 1-8 , in an embodiment of the present invention, a plastic crusher includes a casing 1, a left-toothed crushing roller 17, a right-toothed crushing roller 4, an edge splitter 5 and a middle splitter 16, wherein the left and right sides of the casing 1 Both are provided with opposite and coaxially arranged left-toothed crushing rollers 17 and right-toothed crushing rollers 4, which are characterized in that

[0034] The left inner wall of the housing and the right inner wall of the housing are symmetrically provided with the side splitter plate 5 extending obliquely inward and downward, and the side splitter plate 5 is connected to the left toothed crushing roller 17 1. The right-toothed crushing roller 4 is connected by a transmission adjustment assembly 13, so that when the left-toothed crushing roller 17 and the right-toothed crushing roller 4 rotate, the side splitter plate 5 can reciprocate in a certain range in the left-right direction;

[0035] There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com