Slurry concentration adjusting method and adjusting system for preparing thermoplastic prepreg with slurry method

A slurry concentration and adjustment system technology, applied in the field of prepreg, can solve the problem of resin slurry concentration becoming thinner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

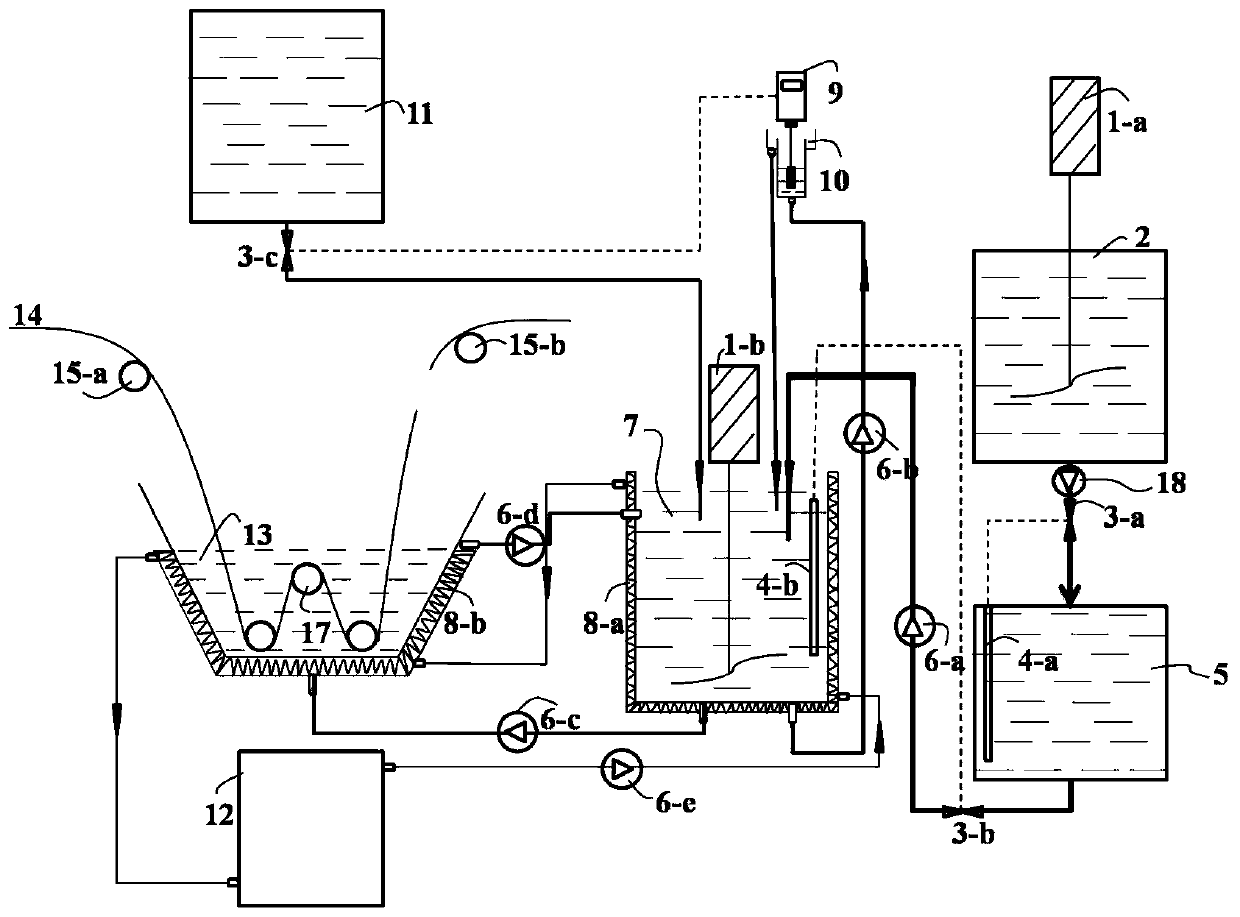

[0027] Such as figure 1 , the slurry concentration adjustment system for preparing thermoplastic prepregs by the slurry method of the present invention includes a slurry dispersion tank 2, a rough slurry mixing tank 5, a buffer rubber mixing tank 7, a sample detection tank 10, a high-concentration slurry storage tank 11, Dipping tank 13.

[0028] The slurry dispersion barrel 2 is used to prepare the slurry, and the concentration of the slurry is the actual slurry concentration required in the production of thermoplastic prepregs. The slurry dispersion barrel 2 is provided with a first mechanical agitator 1-a (using gas source drive) to agitate the slurry to disperse it evenly. Along the slurry flow method, the slurry dispersing barrel 2 is sequentially connected to the coarse slurry mixing barrel 5 , the buffer glue mixing barrel 7 and the glue mixing tank 13 . The slurry coarse mixing tank is used for storage and buffering of low-concentration slurry, which is used as a bac...

Embodiment 2

[0037] This embodiment relates to a practical application of the system in Embodiment 1.

[0038] 1. Add nylon 6 resin powder, water, additives, etc. into the dispersion tank 2, and set the first mechanical agitator 1-a with a rotation speed of 600r / min to disperse the slurry b. Prepare two kinds of slurry with different concentrations: slurry a and slurry b, the concentration of slurry a: 35%, the concentration of slurry b: 20%, the concentrations are all in mass percentage; the viscosity of slurry b is 3.41mPa.s.

[0039] 2. The slurry a is transferred to the high-concentration slurry tank 11 for standby, and the slurry b is transported to the rough mixing tank 5 for standby. The rough mixing barrel 5 is connected to the buffer glue mixing barrel 7, and the low-concentration slurry slurry b is transported into the buffer glue mixing barrel 7 by the first pump 6-a.

[0040] 3. A first liquid level gauge 4-a is provided in the rough mixing tank 5. When the liquid level of the...

Embodiment 3

[0046] This embodiment relates to a practical application of the system in Embodiment 1.

[0047] 1. Add polyether ether ketone resin powder, water, additives, etc. into the dispersion tank 2, and set the first mechanical agitator 1-a with a rotation speed of 800r / min to disperse the slurry b. Prepare two kinds of slurry with different concentrations: slurry a and slurry b, the concentration of slurry a: 50%, the concentration of slurry b: 25%, the concentrations are all in mass percentage; the viscosity of slurry b is 4.33mPa.s.

[0048] 2. The slurry a is transferred to the high-concentration slurry tank 11 for standby, and the slurry b is transported to the rough mixing tank 5 for standby. The rough mixing barrel 5 is connected to the buffer glue mixing barrel 7, and the low-concentration slurry slurry b is transported into the buffer glue mixing barrel 7 by the first pump 6-a.

[0049] 3. A first liquid level gauge 4-a is provided in the rough mixing tank 5. When the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com