Polyurethane soft foam

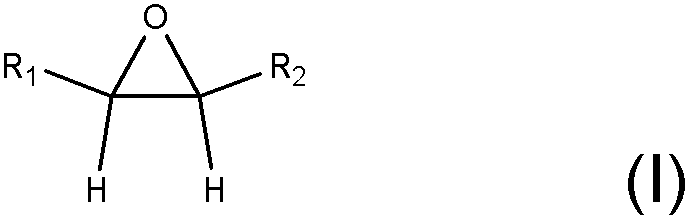

A polyurethane foam, soft technology, applied in the field of car seat cushions/back cushions, can solve the problems of increased foam hardness and closed cell ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

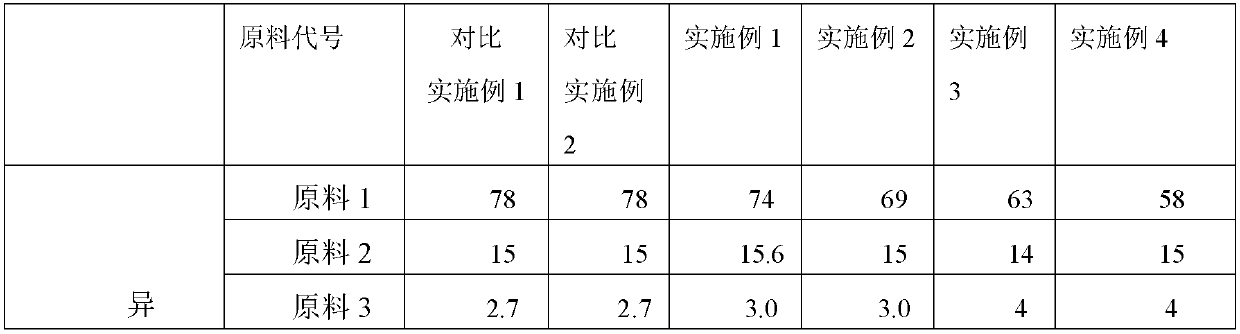

Examples

Embodiment

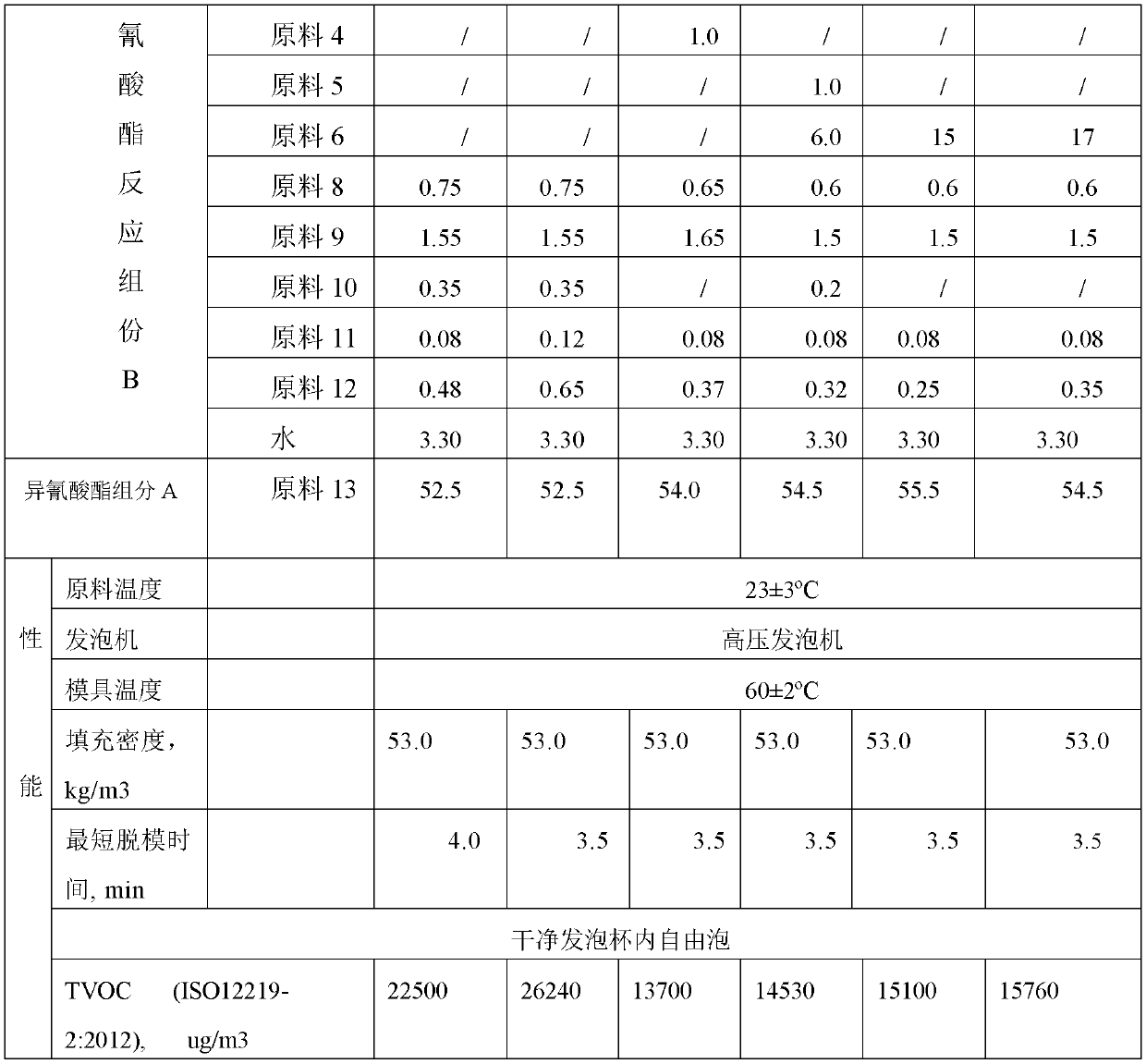

[0128] The test methods of the embodiments are described as follows:

[0129] The shortest demolding time: refers to the shortest time from the time the polyurethane reaction system is introduced into the mold to the time it can be fully demolded after foaming. The basis of the judgment is that the surface of the foam block is smooth and complete without indentation after being demolded from the metal square mold;

[0130] TVOC volatilization: The free foam block made in a clean foaming cup, after being fully cured, is immediately wrapped tightly with food-grade tin foil and food-grade PP film, and sent to a third-party testing agency the next day according to the test standard ISO12219-2: 2012 detects TVOC.

[0131] Material 1-CHE-330N high activity polyether polyol Mw=5000, f=3, hydroxyl value 33.5mgKOH / g, Jiangsu Changhua Polyurethane Technology Co., Ltd.

[0132] Raw material 2-CHP-H45 polymer polyol Mw=7800, f=3, hydroxyl value 21.5mgKOH / g, Jiangsu Changhua Polyurethane Technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com