A kind of evaporation method of revolution type semiconductor evaporation table

An evaporation table, semiconductor technology, applied in semiconductor/solid-state device manufacturing, vacuum evaporation plating, coating and other directions, can solve the problems of low evaporation accuracy, low efficiency, uneven metal film, etc., to achieve high evaporation accuracy, Ensuring precision and uniformity of metal film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below through specific embodiments.

[0041] The embodiment of the present invention discloses an evaporation method of a revolution type semiconductor evaporation table,

[0042] S1. Preliminary preparation of equipment

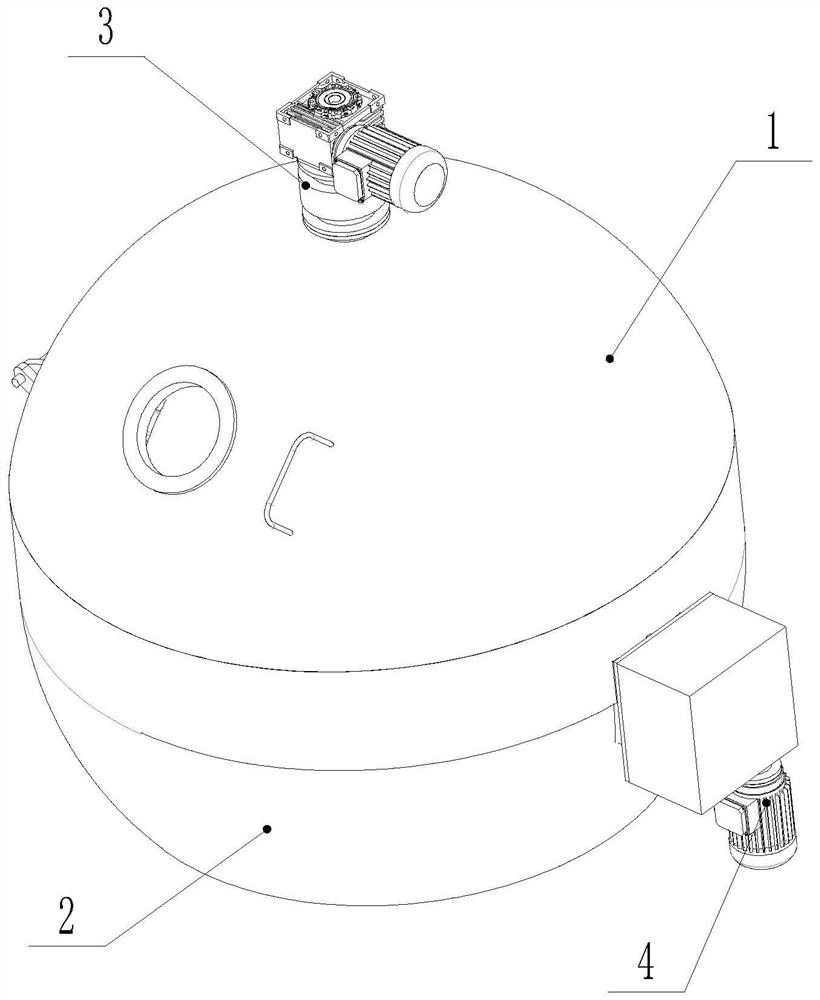

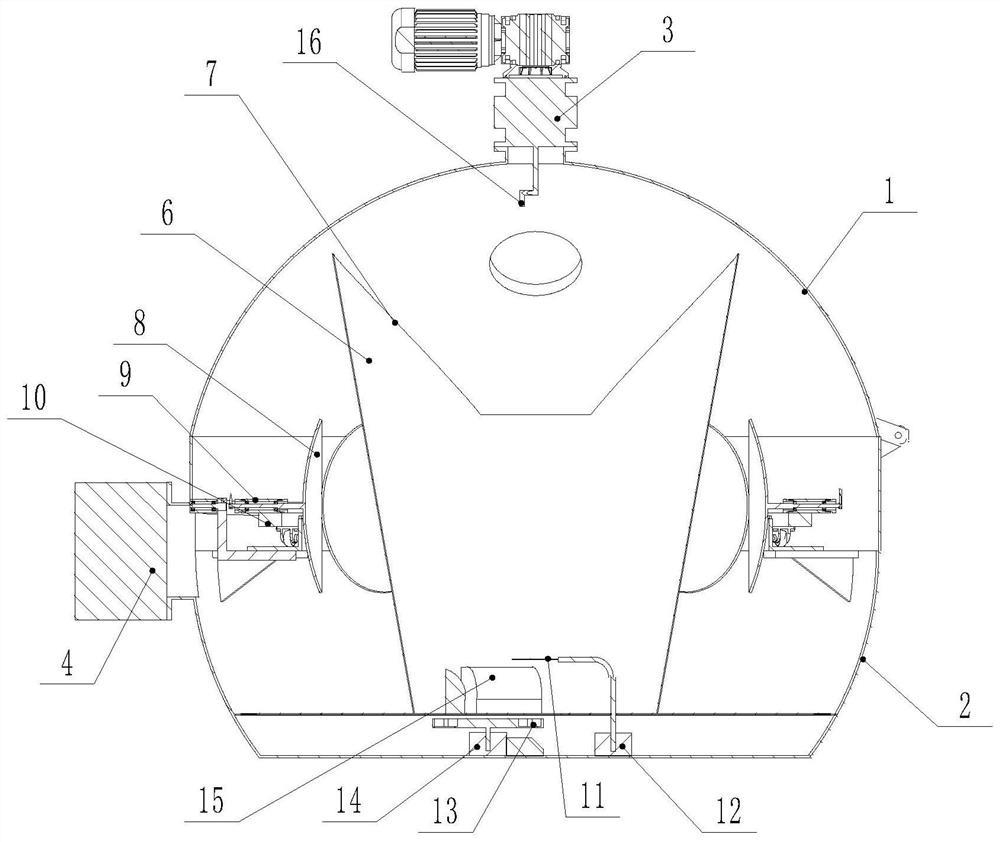

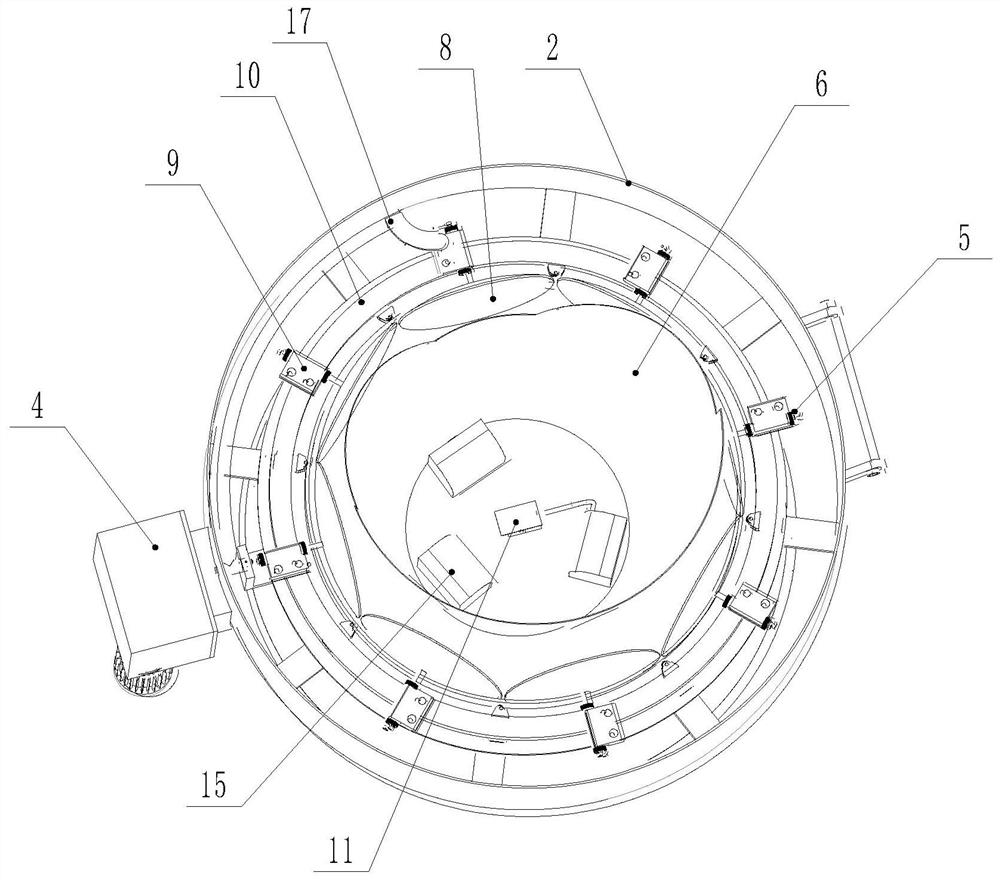

[0043] S11. Provide a revolving evaporation table, the evaporation table includes a lower casing 2 and an upper cover 1, the inner space between the lower casing 2 and the upper cover 1 forms an evaporation chamber, and the bottom of the evaporation chamber is provided with a crucible 13 , the metal used for evaporation is placed in the crucible 13, the bottom of the evaporation chamber is provided with an electron beam generator and a vacuuming device for evacuating the evaporation chamber, and a rotating ring is rotatably installed on the inner wall of the lower casing 2 10. The rotating ring 10 is driven by a rotating power device. A number of slide covers 8 are evenly distributed on the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com