Method for controlling plurality of polycrystalline furnaces to run by one vacuum pump of polycrystalline furnace stage

A technology for vacuum pumps and polycrystalline furnaces, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth. It can solve the problems of reduced service life of slide valves, large consumption of lubricating oil, and noise pollution, and reduce the frequency of failures. The effect of preventing major safety accidents and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

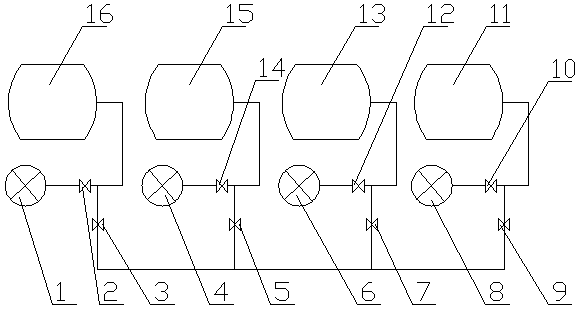

[0019] In this embodiment, four polycrystalline furnaces are used to describe and illustrate the implementation method of the invention.

[0020] like figure 1 As shown, one vacuum pump of the polycrystalline furnace table in the present invention controls the operation modification method of multiple polycrystalline furnaces, and the specific method is as follows:

[0021] (1) Connect adjacent polycrystalline furnaces in series before operation; see figure 1 , the first polycrystalline furnace 16, the second polycrystalline furnace 15, the third polycrystalline furnace 13 and the fourth polycrystalline furnace 11 are connected in series with each other by a series pipeline, and the first polycrystalline furnace 16 is connected with a first vacuum pump 1 by a pipeline, The first V8 valve 2 is provided on the pipeline between the first polycrystalline furnace 16 and the first vacuum pump 1; the first V9 valve 3 is provided between the connecting pipe of the first polycrystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com