Steel-concrete combined beam bridge deck slab

A panel, steel-concrete technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of low torsional stiffness, lack of tensile bearing capacity, material spillage, etc., and achieve the effect of weak hoisting capacity and low lateral splitting stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

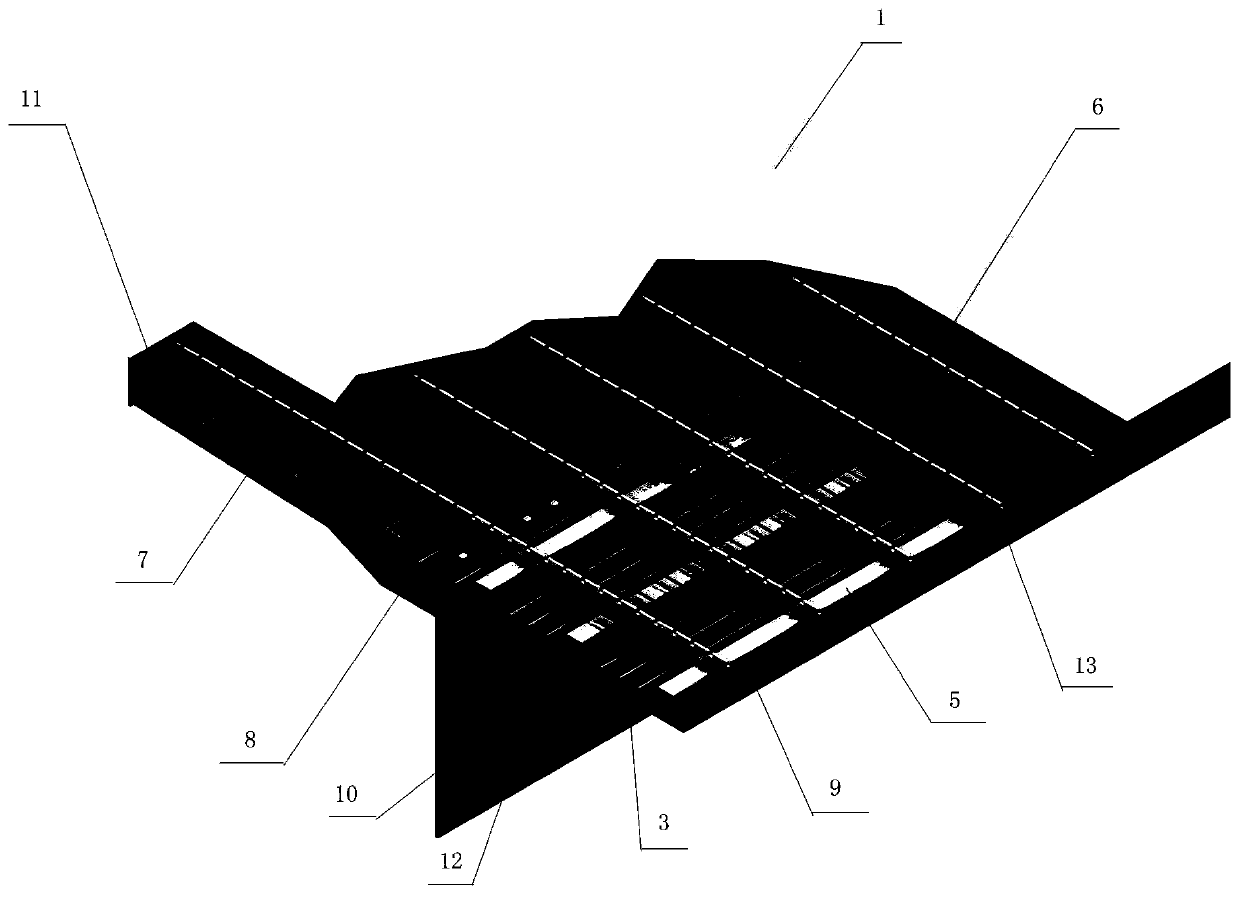

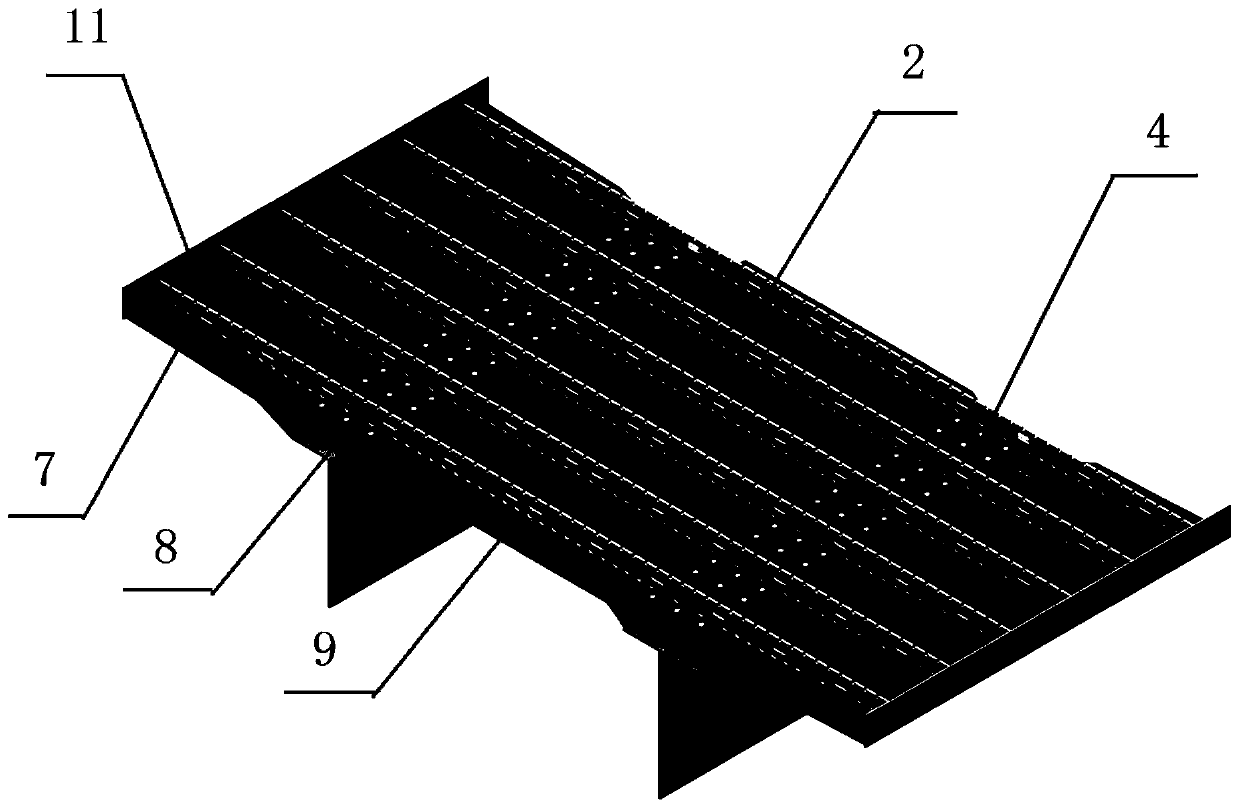

[0024] A steel-concrete composite girder bridge deck, comprising concrete 1 and a steel base plate, concrete 1 poured above the steel base plate, also comprising spaced apart transverse opening stiffening plates 2 and spaced longitudinal prestressed plates 5, the transverse openings The stiffening plate 2 is installed on the upper surface of the steel floor, and the longitudinal prestressing plate 5 runs through the stiffening plate 2 with transverse openings.

Embodiment 2

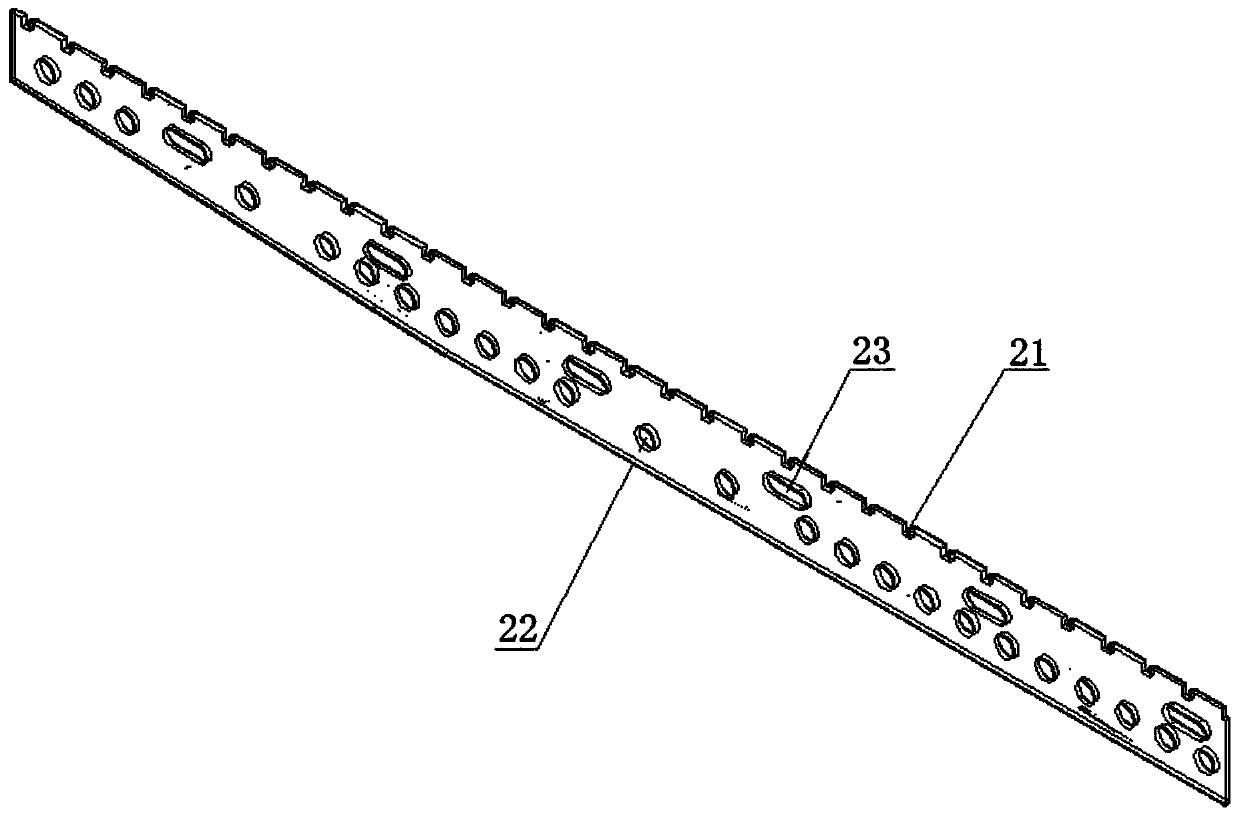

[0026] A steel-concrete composite girder bridge deck, comprising concrete 1 and a steel base plate, concrete 1 poured above the steel base plate, also comprising spaced apart transverse opening stiffening plates 2 and spaced longitudinal prestressed plates 5, the transverse openings The stiffening plate 2 is installed on the upper surface of the steel floor, and the longitudinal prestressing plate 5 runs through the stiffening plate 2 with transverse openings. There is a reinforcement mesh 6 on the upper side of the steel base plate, and the reinforcement mesh 6 is arranged on the upper side of the transverse perforated stiffening plate 2, and the upper end of the transverse perforated stiffening plate 2 is provided with an open-shaped reinforcement notch 21, and the reinforcement mesh 6 passes through the reinforcement notch. 21 is connected with transverse opening stiffener plate 2.

Embodiment 3

[0028] A steel-concrete composite girder bridge deck, comprising concrete 1 and a steel base plate, concrete 1 poured above the steel base plate, also comprising spaced apart transverse opening stiffening plates 2 and spaced longitudinal prestressed plates 5, the transverse openings The stiffening plate 2 is installed on the upper surface of the steel floor, and the longitudinal prestressing plate 5 runs through the stiffening plate 2 with transverse openings. A through hole 22 is provided in the middle of the stiffened plate with transverse holes 2 , and a shear member 3 penetrating through the stiffened plate with transverse holes 2 is included, and the shear member 3 penetrates through the through hole 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com