Electromagnetic adsorption clamping type protection bearing device

A bearing protection and clamping technology, applied in the field of magnetic suspension bearing system, can solve problems such as vibration, impact and damage of magnetic suspension bearing system, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

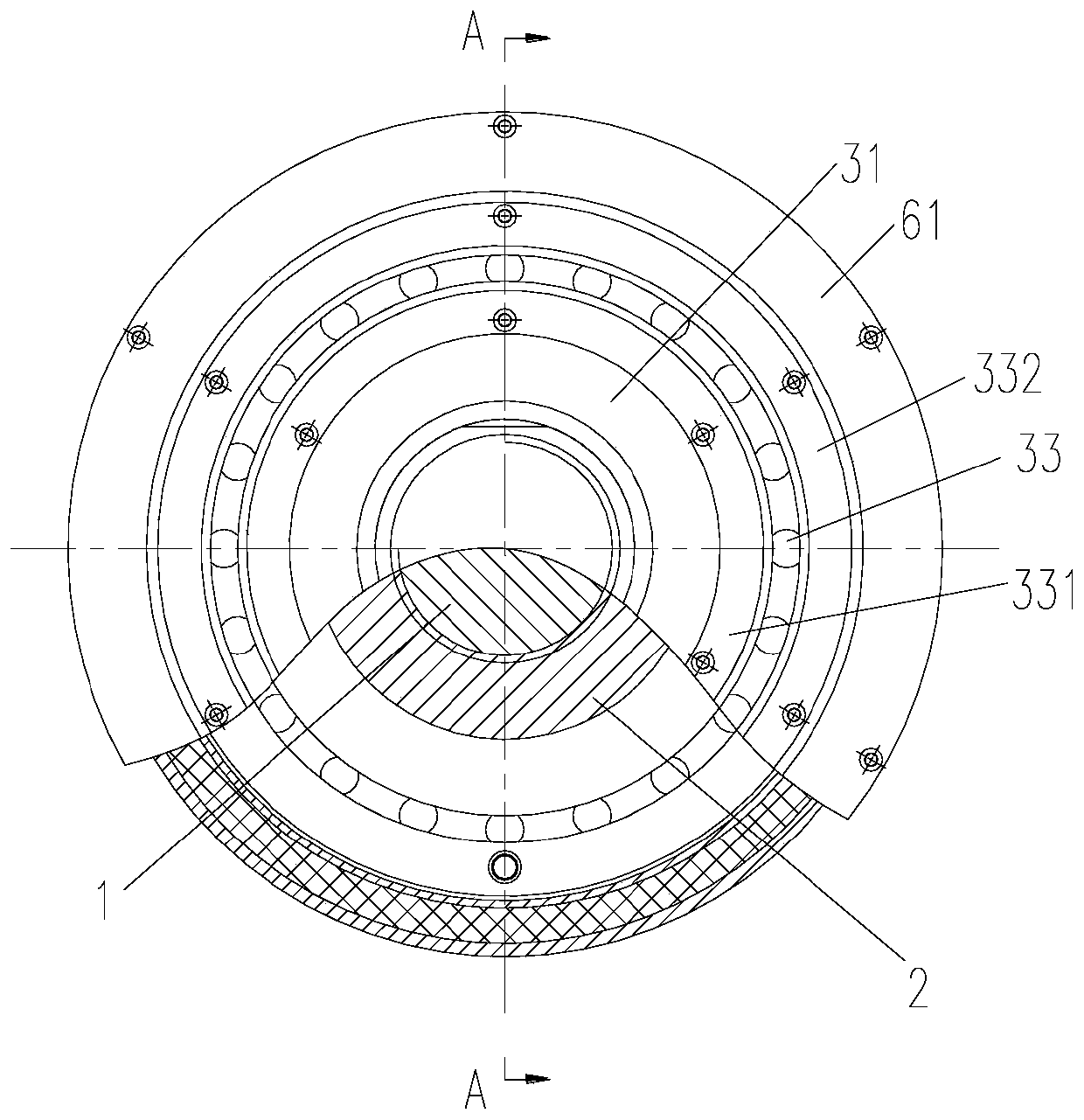

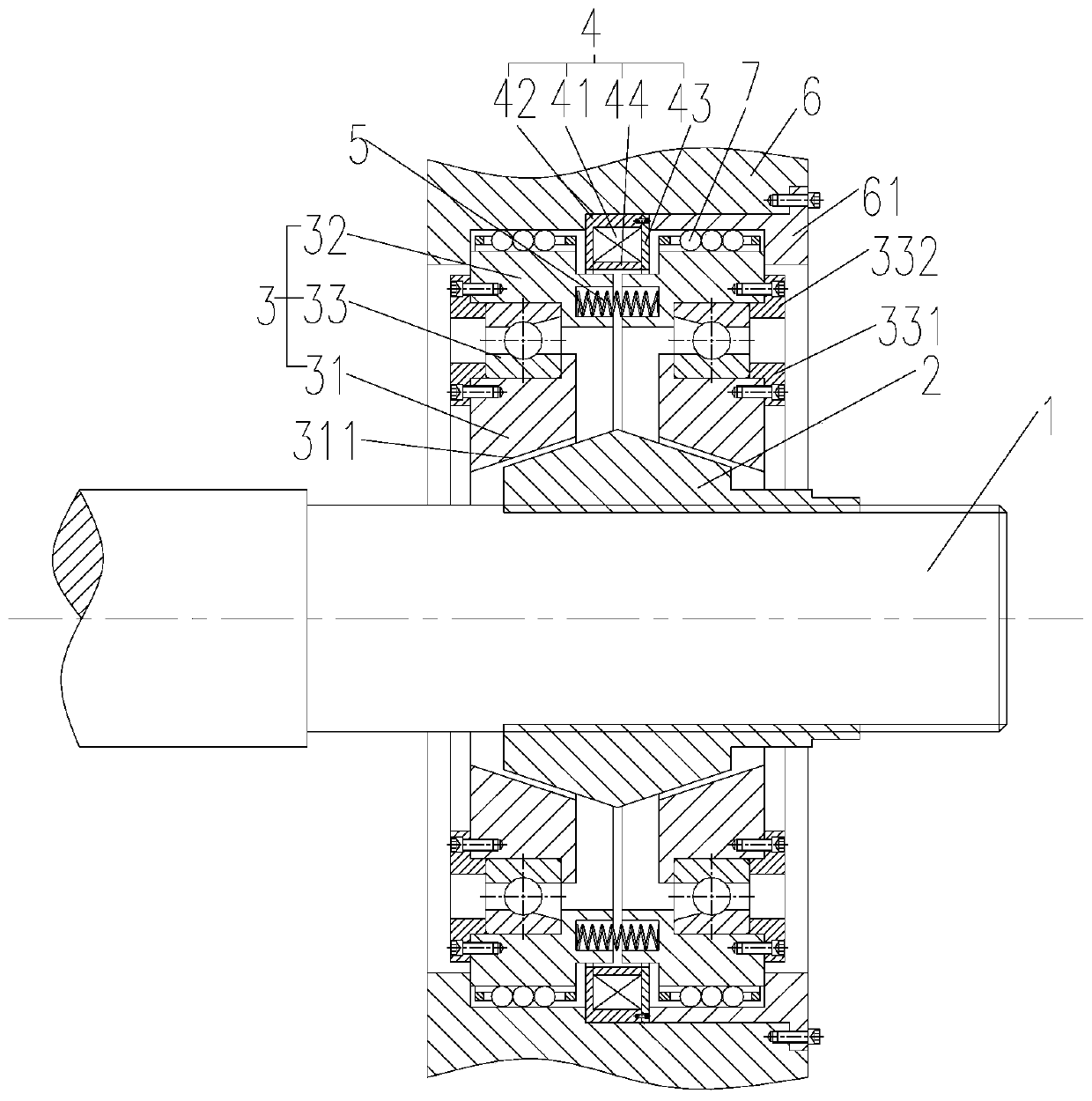

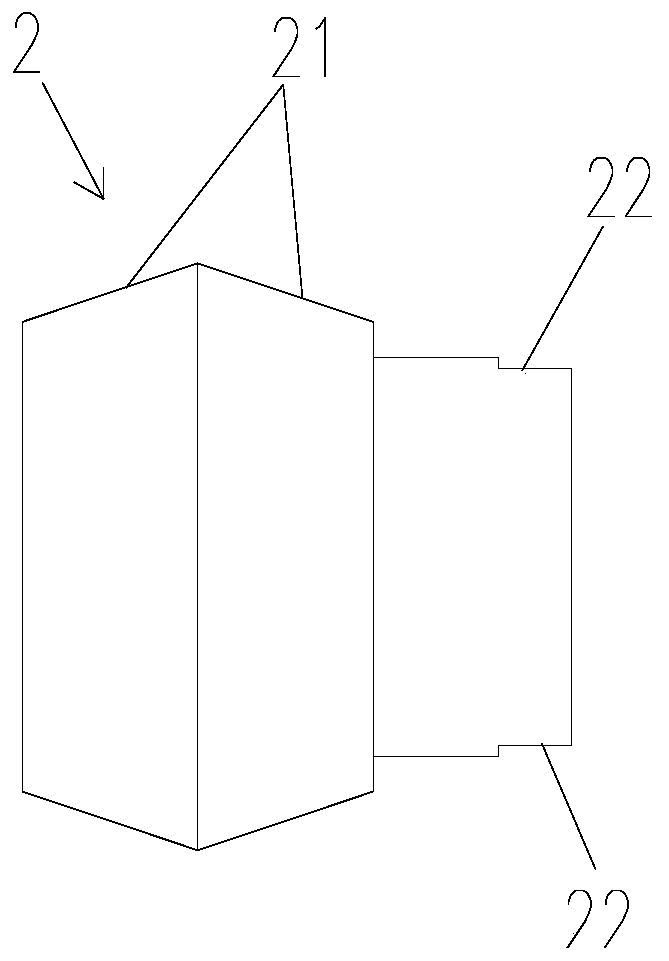

[0031] Such as Figure 1-4 As shown, this embodiment provides an electromagnetic adsorption clamping protective bearing device, which includes a double-cone sleeve 2, a support assembly 3 and an electromagnetic adsorption assembly 4. The double-cone sleeve 2 is sleeved on the rotor 1 to support The components 3 are two groups, and the two groups of support components 3 are axially slidably assembled on the outer circumference of the double-cone sleeve 2, and the two groups of support components 3 are respectively arranged corresponding to the two conical surfaces 21 of the double-cone sleeve 2. The initial state Next, there is a gap between the two sets of support assemblies 3 and the two tapered surfaces 21, and there is also a gap between the two sets of support assemblies 3. The two sets of support assemblies 3 slide toward each other under the action of the electromagnetic adsorption assembly 4, and the two sets of support assemblies The components 3 respectively connect w...

Embodiment 2

[0041] Such as Figure 5-6 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that the electromagnetic adsorption components 4 in this embodiment are divided into two groups and are respectively arranged on both sides of the two groups of supporting components 3, and the two groups of electromagnetic adsorption components 4 are driven The member 9 and the baffle 321 drive the supporting assembly 3 to slide axially.

[0042] Specifically, the two sets of support assemblies 3 are installed axially side by side on the inner peripheral surface of the frame 6 through the ball sleeves 7, without the need for an end cover. There is no need to set an extension between the two support positioning parts 32 of the two groups of support assemblies 3, and there are installation grooves on the opposite two surfaces of the two support positioning parts 32, and the two ends of the elastic member 5 are respectively placed in the two installation grooves In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com