Online thickness measurement system for ultra-wide PC sheet

A PC sheet, thickness measurement technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low degree of automation, high rejection rate of PC sheet, no special thickness gauge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

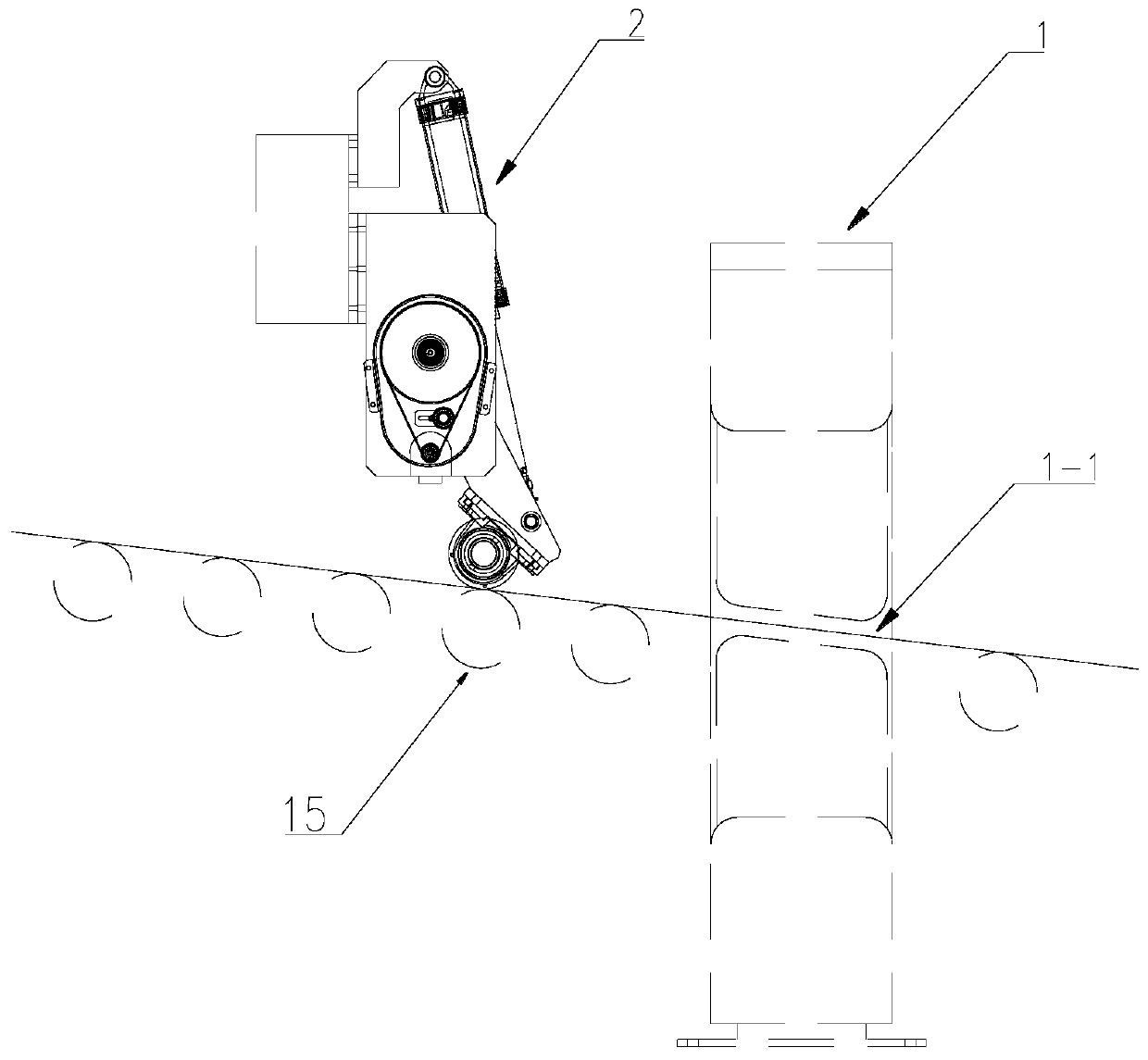

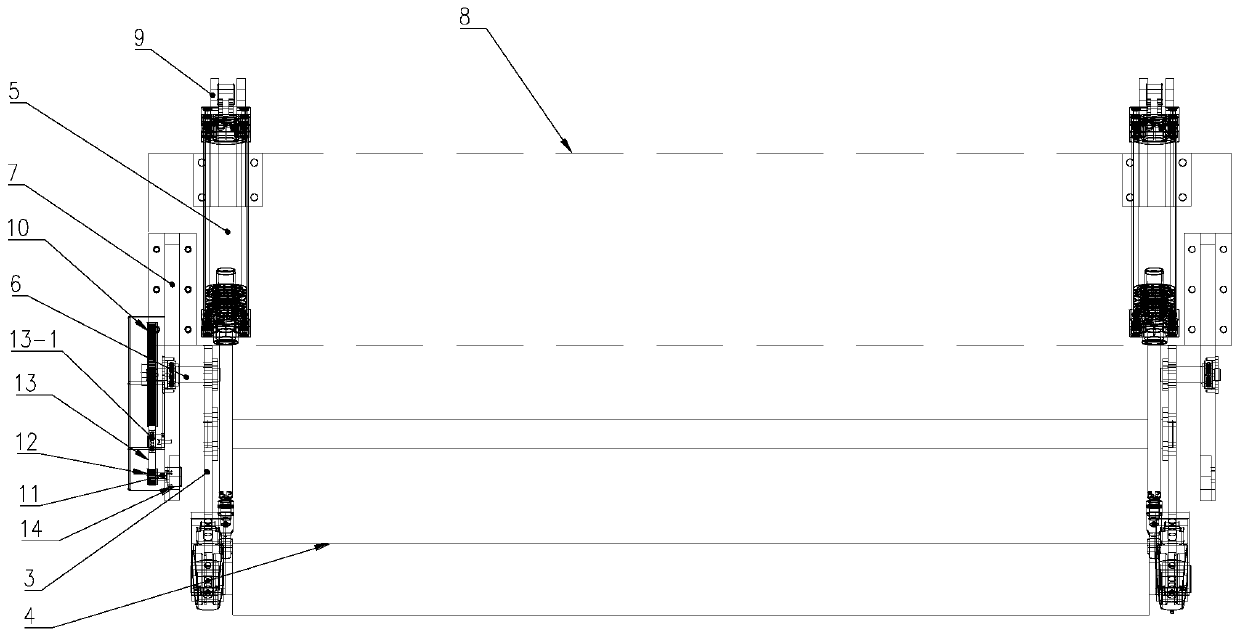

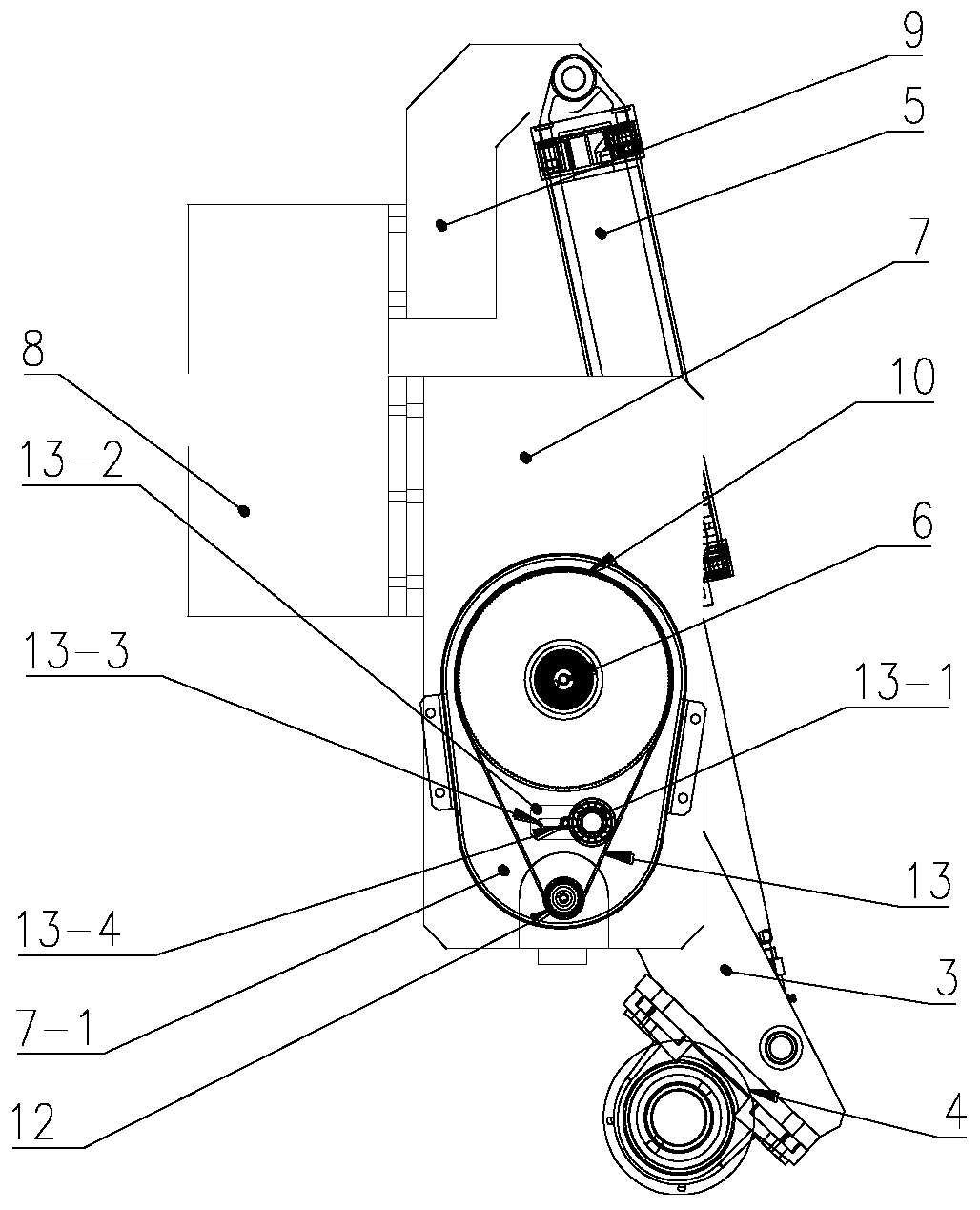

[0018] see Figure 1 to Figure 3 , an online thickness measurement system for ultra-wide PC sheets, comprising a thickness gauge 1 and a thickness change monitoring device 2 . The thickness gauge 1 is installed on the PC sheet production line, and the thickness gauge 1 is provided with a probe for detecting the thickness of the PC sheet, and the probe is located on the thickness gauge 1 to allow the PC sheet to pass through the detection port 1- In 1, the passing PC sheet is detected by the left and right reciprocating motion of the probe, and the thickness gauge 1 feeds back the thickness deviation of the PC sheet detected by the probe scanning to the automatic mold, so that the automatic mold automatically adjusts the extrusion thickness of the raw material. The thickness change monitoring device 2 includes a pressing arm 3 , a pressing roller 4 and an air cylinder 5 . The fixed end of described pressing arm 3 is hinged on a mounting plate 7 by rotating shaft 6, and describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com