Real-time cable insulation layer thickness monitoring method and device

A technology for cable insulation and real-time monitoring, applied in measuring devices, optical devices, instruments, etc., can solve the problem of low safety of electric spark source, inability to monitor the thickness and position of cable insulation layer thickness in real time, and inefficient detection methods, etc. problems, to achieve the effects of accurate and comprehensive monitoring information, light weight, and anti-electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0034] An embodiment of the present invention provides a real-time monitoring device for the thickness of a cable insulation layer.

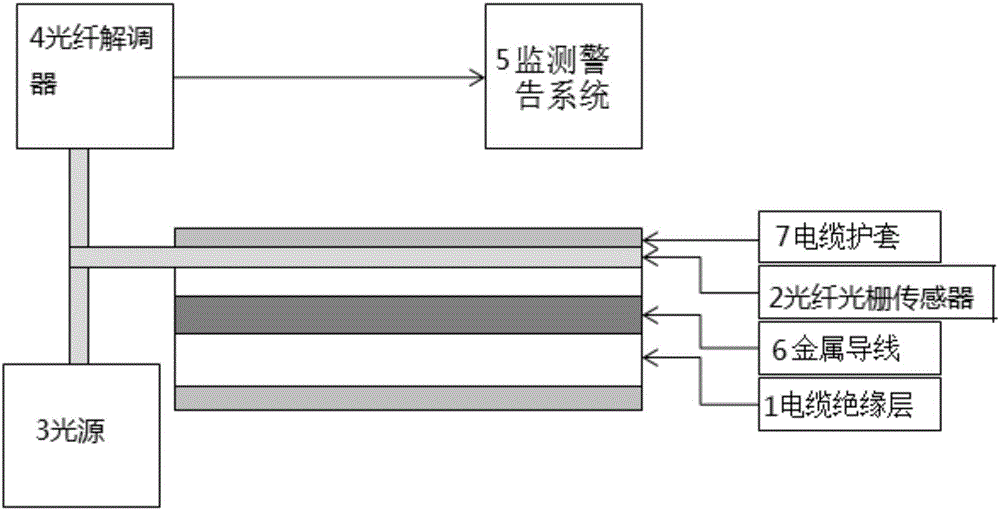

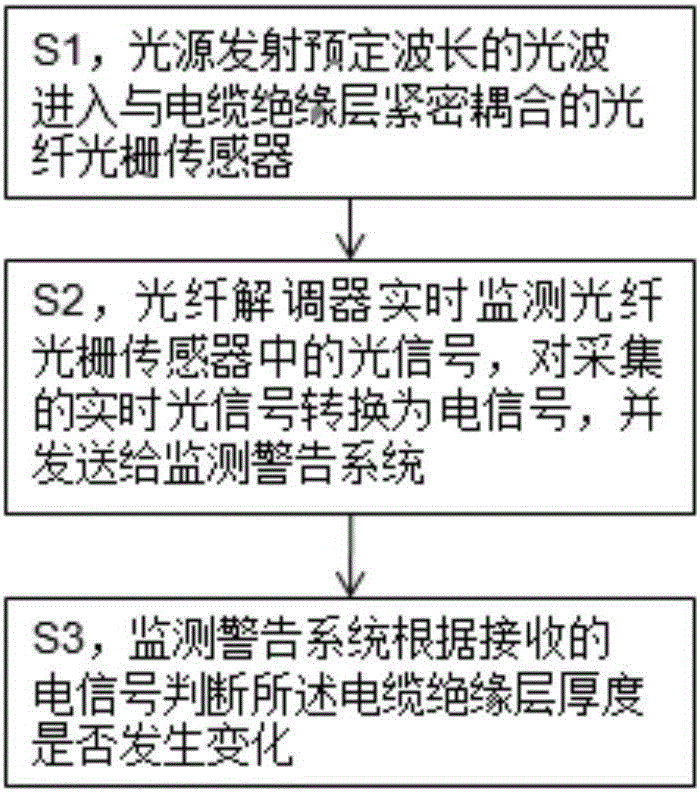

[0035] Such as figure 1 As shown, a real-time monitoring device for the thickness of the cable insulation layer, the cable includes a metal wire and a cable insulation layer wrapping the metal wire, and the real-time monitoring device includes a fiber grating sensor, a light source, a fiber optic demodulator and a monitoring and warning system. The optical fiber grating sensor is closely coupled with the cable insulation layer, the optical fiber grating sensor is respectively connected with the light source and the optical fiber demodulator, and the optical fiber demodulator is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com