Brake, braking shoe pad abrasion alarm mechanism and alarm method thereof and EBS system

A technology of brake shoes and brakes, applied in the direction of brake types, mechanical equipment, etc., can solve the problems of left and right wheel braking torque imbalance, braking torque drop, braking deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

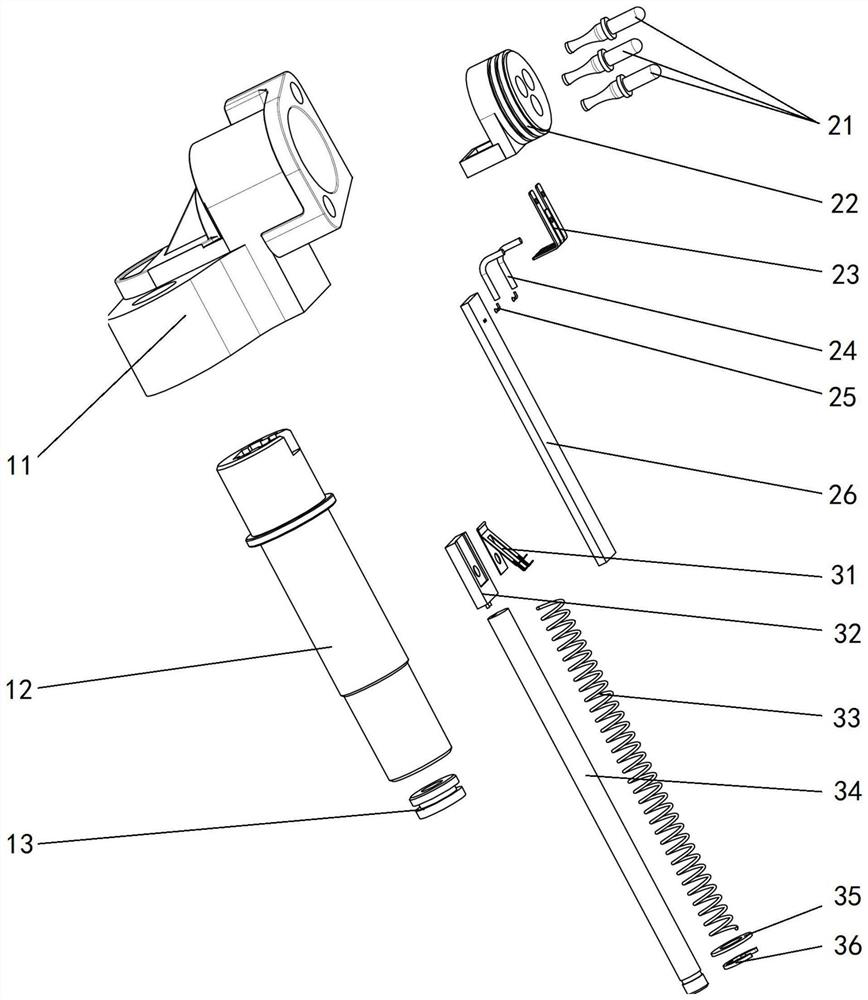

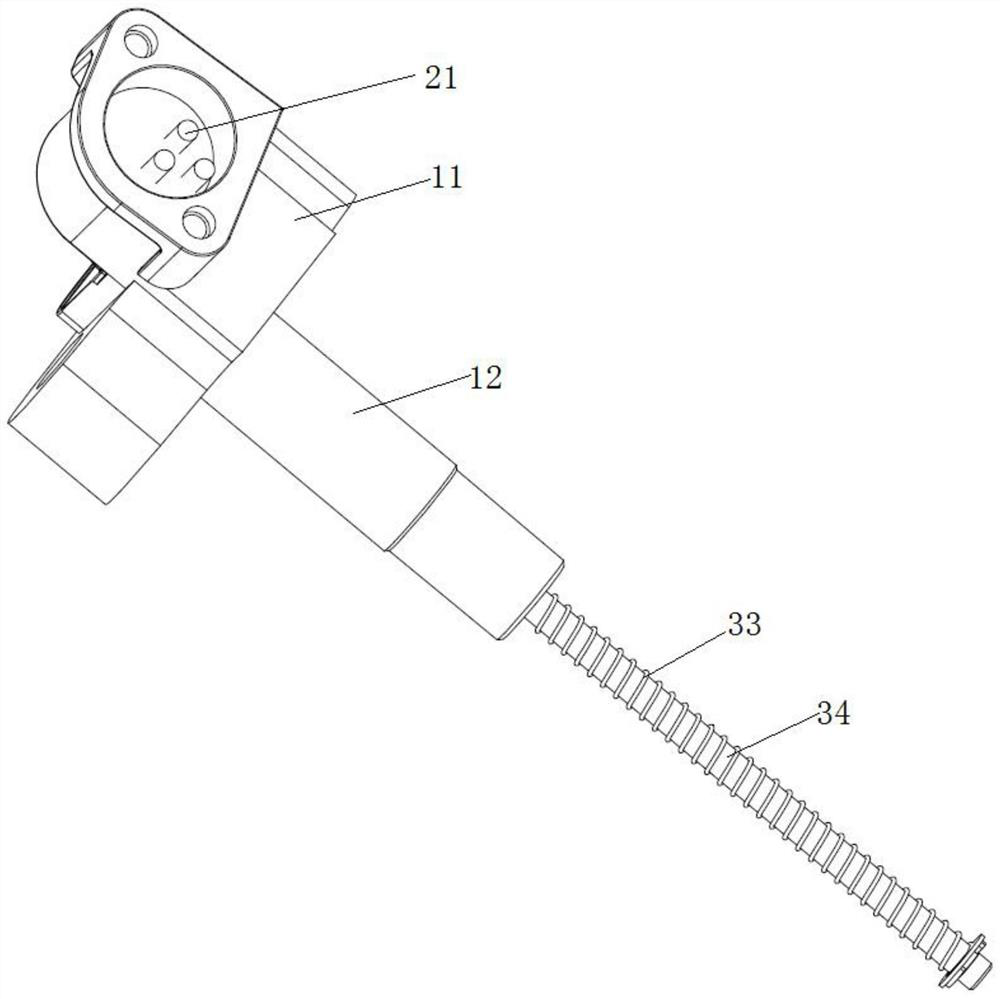

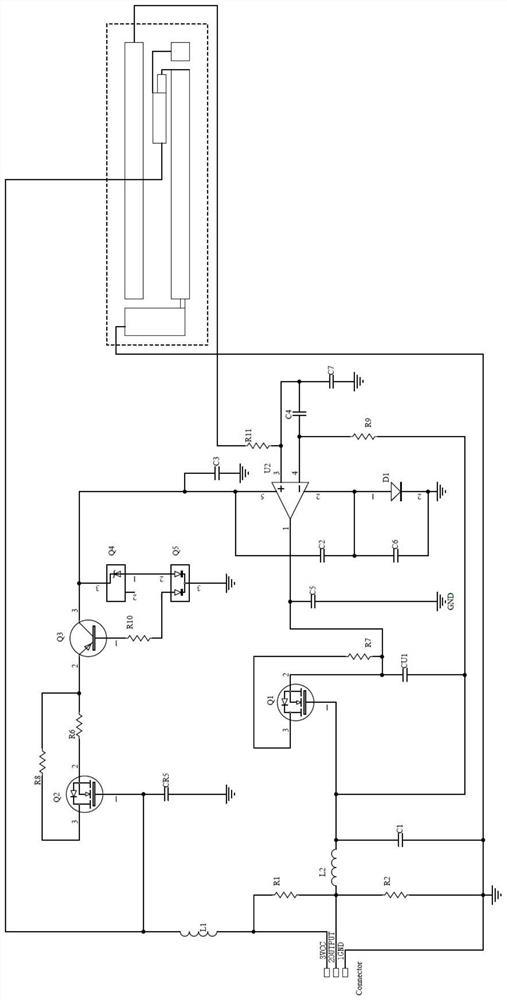

[0033] see Figure 1 to Figure 6 , the embodiment of the present invention provides a brake shoe wear alarm mechanism, which includes an alarm that can warn and a measuring piece that can be extended as the thickness of the brake shoe 42 becomes smaller. The abutting end on the brake shoe 42; the measuring device also includes a conductive area arranged along the elongated direction of the measuring piece and can be moved on the conductive area by the measuring piece and moved on the measuring piece When the movable shoe 42 fails, it moves to the movable block 32 outside the conductive area, and the movable block 32, the conductive area and the alarm are connected in series. In this embodiment, the wear state of the brake shoe 42 is monitored in real time through the change of the measuring piece along with the wear of the brake shoe 42, and an alarm is issued to remind the driver when it is out of the set conductive area. . Specifically, the abutting end of the measuring pi...

Embodiment 2

[0038] see Figure 1 to Figure 6 An embodiment of the present invention provides a brake, including a brake shoe 42 and the above-mentioned brake shoe wear alarm mechanism, and the abutting end of the measuring element is abutted against the brake shoe 42 . In this embodiment, the above-mentioned alarm mechanism 100 is used on a brake, either on a disc brake or on a drum brake. The wear state of the brake shoe 42 is monitored in real time by the change of the measuring piece along with the wear of the brake shoe 42 , and an alarm is issued to remind the driver when it leaves the set conductive area. Specifically, the abutting end of the measuring piece is close to the brake shoe 42, since the measuring piece can elongate as the thickness of the brake shoe 42 becomes smaller, after the brake shoe 42 is worn and thinned, The measuring piece can be elongated; and the elongated measuring piece can move on the guiding area with the movable block 32, and now the movable block 32 is...

Embodiment 3

[0040] see Figure 1 to Figure 6 An embodiment of the present invention provides an EBS system, which includes the above-mentioned brake shoe wear alarm mechanism, and the brake shoe wear alarm mechanism provides the EBS system with information on changes in the thickness of the brake shoe 42 . In this embodiment, the real-time thickness change information of the brake shoe 42 is provided to the EBS system to make the EBS system more complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com