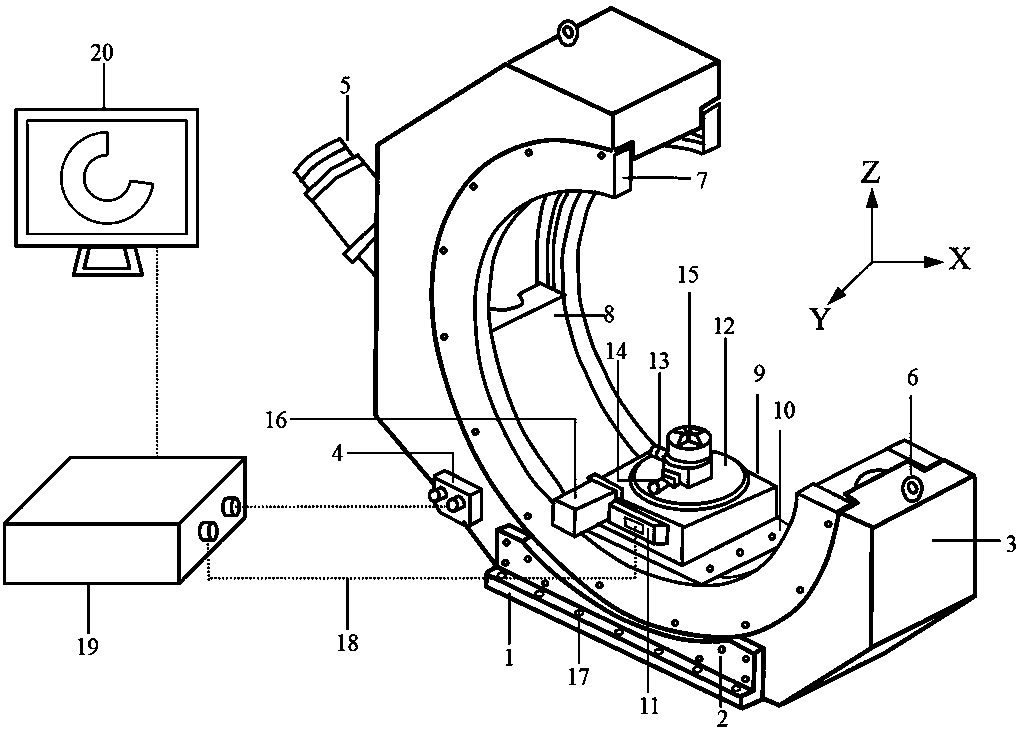

Angle measuring device and using method thereof

A technology of angle measurement and main frame, which is used in measurement devices, material analysis using wave/particle radiation, instruments, etc., which can solve the problems of small space and load-bearing, and small internal space and load-bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]For a sample with a volume of about 100 cubic centimeters and a weight of about 8 kg, the steps of using the angle measuring device of the present invention are as follows:

[0051] (a) Main frame installation

[0052] The base 1 is installed on the bottom of the main frame 3 by screws 2, the suspension ring 6 is installed and fixed on the upper end of the main frame 3, and the port 4 and the drive motor 5 with a power of 750 watts are installed on the side of the main frame 3; the main frame 3 is built in The arc-shaped guide rail 7 is installed, and the slider 8 is installed on the guide rail; the movement of the slider 8 on the guide rail 7 is controlled by the driving motor 5, thereby realizing the control of different inclination angles.

[0053] (b) 3D table setup

[0054] Install and fix the chassis 10 of the three-dimensional table 9 on the slider 8 through screws 2, install the interface 11 and the rotating shaft 16 on the side of the three-dimensional table 9 ...

Embodiment 2

[0062] For the test of large samples (such as volume ≥ 1000 cubic centimeters, weight ≥ 10 kg) and in-situ measurement scenarios, or the situation where the three-dimensional table 9 in Example 1 is not suitable for the actual measurement of samples, it is necessary to use adapter tools or equipment Replace the 3D table with 9. At this time, in step b of Embodiment 1, the adapter tool or equipment is installed and fixed on the slider 8 through the screw 2 . Other usage steps are consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com