An automatic fried food system

A fried food, automatic technology, applied in food oven, food science, oil/fat baking, etc., can solve the problems of shortened cooking oil use time, less frying time, heavy workload, etc., to achieve stable quality and avoid If the oil temperature is too high, the effect of prolonging the service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

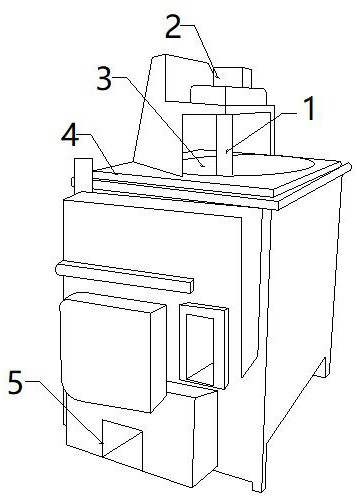

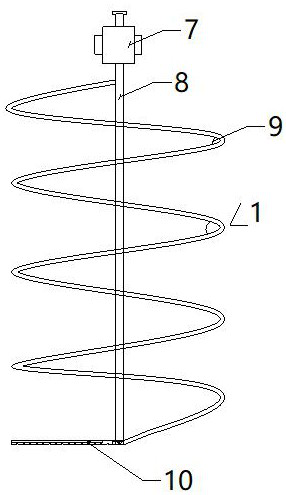

[0029] see Figure 1-Figure 3 , the present invention provides an automatic fried food system, its structure includes a tumbling and stirring mechanism 1, a motor 2, a fryer 3, a frame 4, an inlet and outlet 5, and a fryer 3 is placed in the middle of the top surface of the frame 4, A tumbling and stirring mechanism 1 is provided in the middle of the fryer 3, and the top of the tumbling and stirring mechanism 1 is mechanically connected to the motor 2, and an inlet and outlet 5 are installed at the bottom of the side of the frame 4.

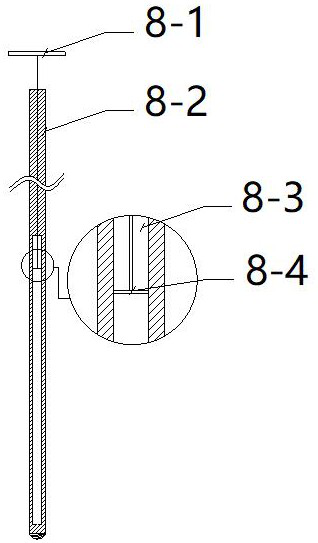

[0030] The tumbling stirring mechanism 1 is provided with a shaft head 7, a main shaft 8, and a stirring piece 9, one end of the main shaft 8 is fixedly connected with the shaft head 7, and a stirring piece 9 is installed on the main shaft 8, and the stirring piece 9 is a cylindrical rod The curved sinusoidal structure can stir the materials of different volumes and qualities in the fryer 3 from top to bottom to avoid black frying.

[0031] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com