Sheet metal part stamping hole correcting device and method

A technology for punching holes and sheet metal parts, which is applied in the field of correction devices for punching holes in sheet metal parts. Effects of cost reduction and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

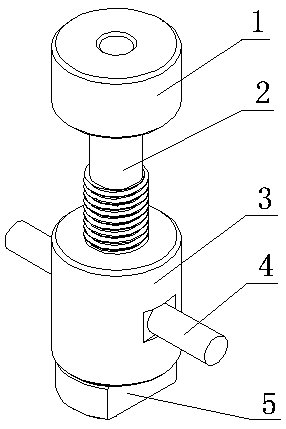

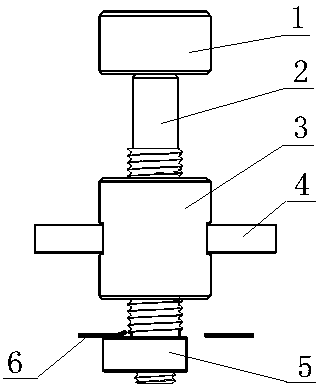

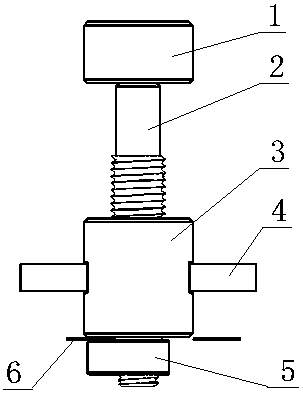

[0023] Such as figure 1 A correction device for stamping holes of sheet metal parts shown, including orthopedic pressure block 3 and orthopedic bottom block 5 arranged up and down, the orthopedic pressure block 3 and the orthopedic bottom block 5 are installed on the screw rod 2 through threads respectively, and the screw rod 2 The upper end of the handle 1 is equipped with, and the orthopedic pressure block 3 is equipped with a handle 4 for pushing it to move on the screw rod 2 . The maximum external dimension of the orthopedic bottom block 5 is less than the diameter of the sheet metal stamping hole, and one side of the orthopedic bottom block 5 has a vertically arranged side plane, and the threaded hole on the orthopedic bottom block 5 is close to the side plane. The orthopedic pressure block 3 and the orthopedic bottom block 5 are made of flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com