Sealing structure for spraying equipment for friction press

A technology of friction presses and spraying equipment, applied in mechanical equipment, metal processing equipment, heating/cooling equipment, etc., can solve problems such as liquid leakage and poor sealing effect of spraying liquid delivery pipelines, and achieve resource and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

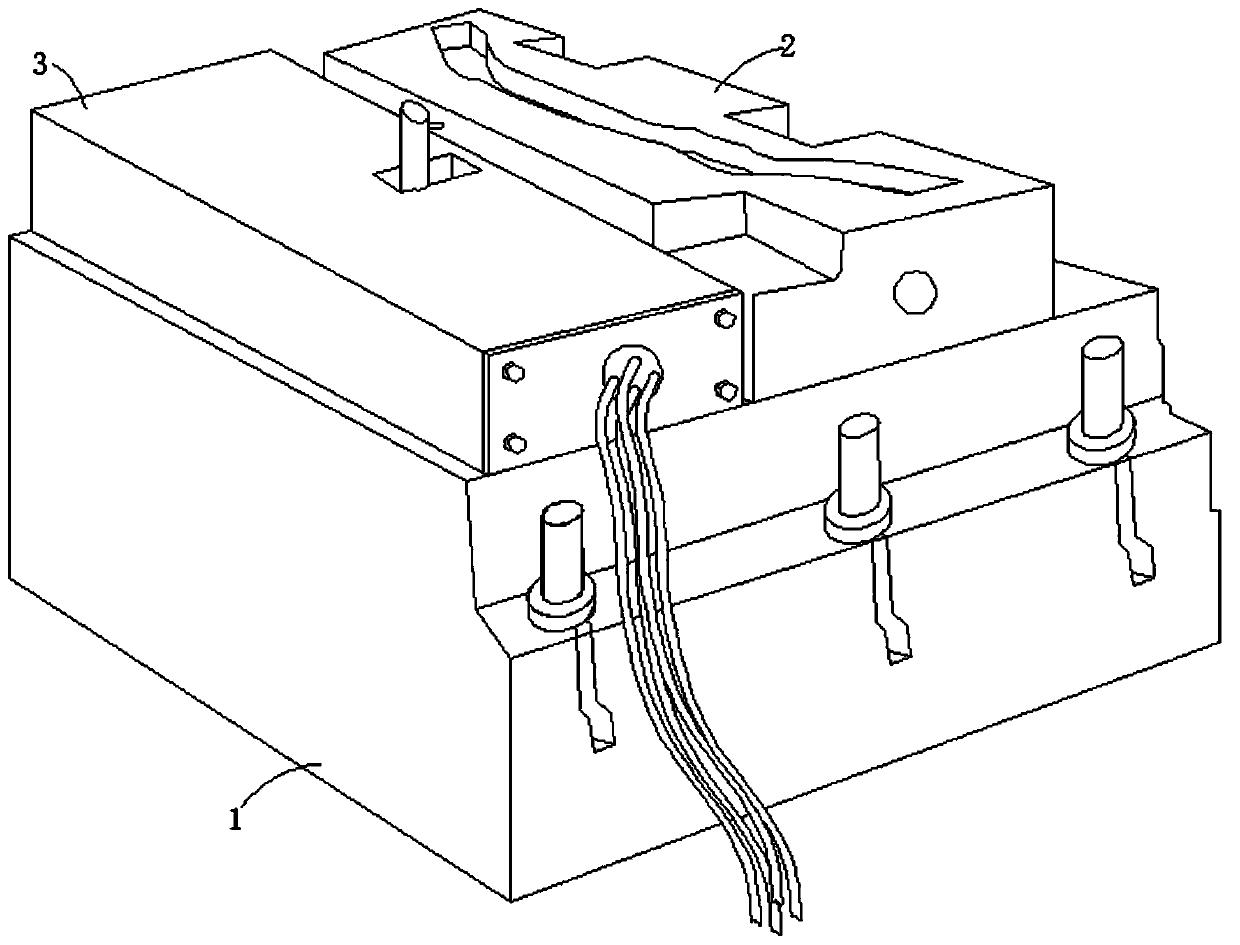

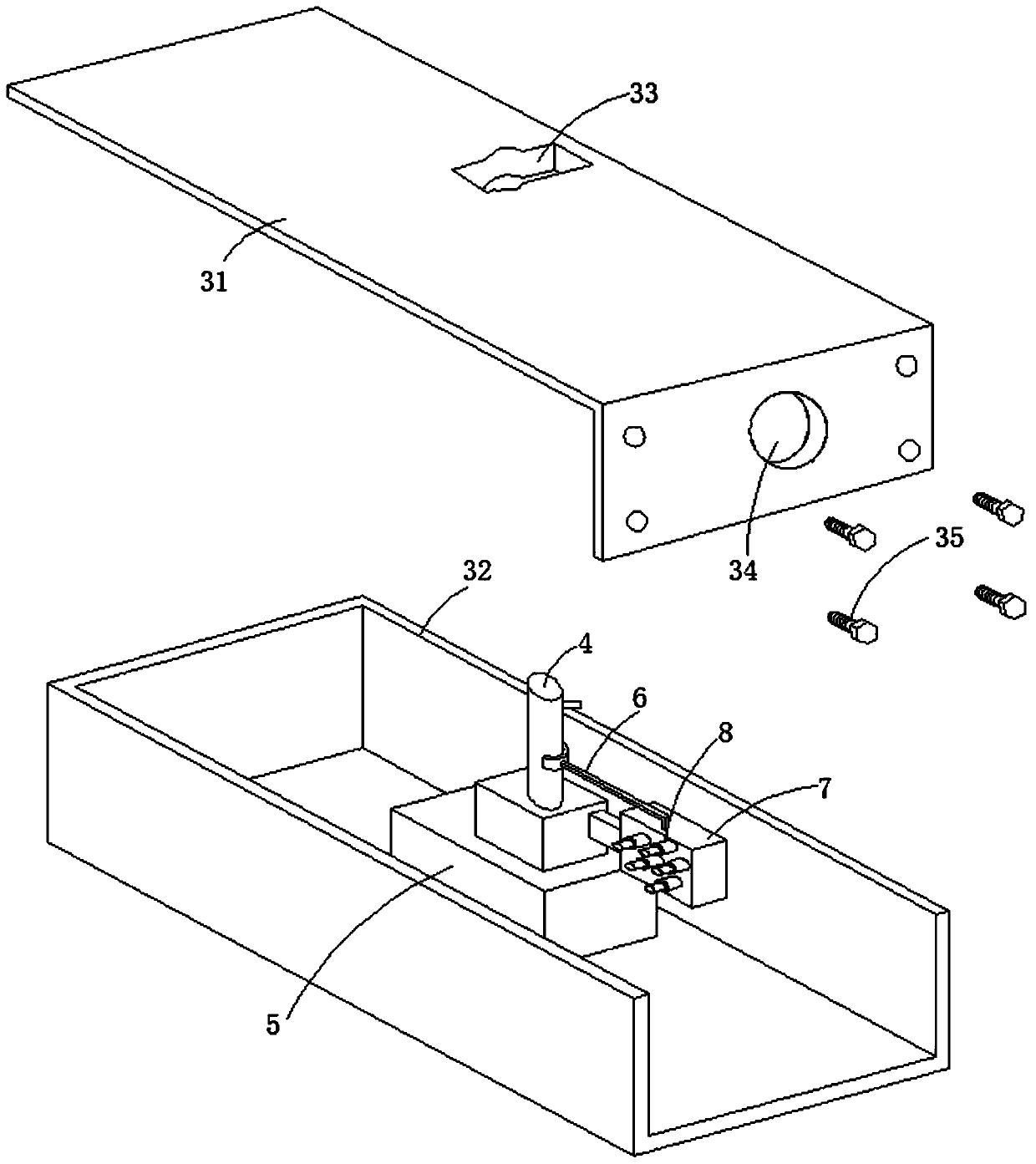

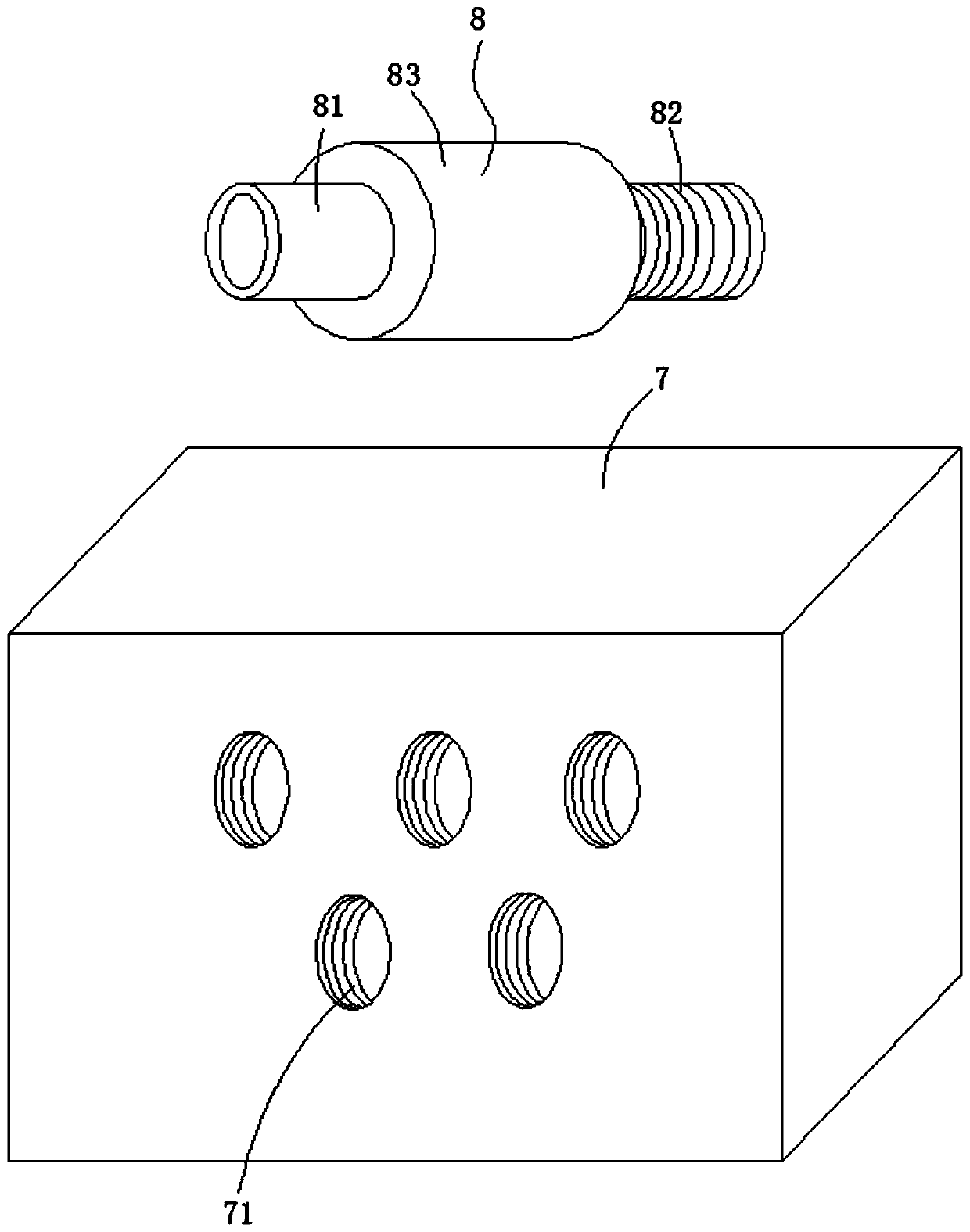

[0031] Such as Figure 1-5 As shown, a sealing structure for friction press spraying equipment is proposed in this embodiment, including a base 1, a template 2 and a spraying device 3, the template 2 and the spraying device 3 are all arranged on the base 1, and the spraying device 3 includes the installation box cover 31 and the installation box body 32, the installation box cover 31 covers the installation box body 32, and the installation box cover 31 and the installation box body 32 are connected by fixing screws 35, the horizontal plate of the installation box cover 31 A moving through hole 33 is opened, and a side through hole 34 is opened on the vertical plate of the installation box cover 31. The installation box body 32 is provided with a shower head 4 through the lifting mechanism 5, and the shower head 4 moves through the moving through hole 33, and the spray head 4 moves through the moving through hole 33. The shower head 4 is set through the liquid spray box 7 thro...

Embodiment 2

[0035] Such as Figure 5 As shown, the difference between embodiment 2 and embodiment 1 is that in embodiment 2, the end of the connecting threaded pipe 83 away from the fixed pipe 81 is fixedly provided with the first magnet pipe 11, and the first magnet pipe 11 is sleeved on the connecting pipe 82 Outside, the nut 13 is fixedly provided with the second magnet tube 15 towards one end of the connecting threaded pipe 83. Since the first magnet tube 11 and the second magnet tube 15 are attracted to each other, the connecting threaded pipe 83 and the nut 13 are formed When resisting extrusion, a better extrusion effect can be achieved.

Embodiment 3

[0037] Such as Figure 6 As shown, the difference between embodiment 3 and embodiment 2 and embodiment 1 is that in embodiment 3, the nut 13 is provided with a first moving hole 14 on the inner tube facing the side where the threaded pipe 83 is connected, and the second magnet tube 15 The inner tube is provided with a second moving hole 16, and the second moving hole 16 is connected with the first moving hole 14 to form a complete extrusion hole, and the diameter of the end of the extrusion hole close to the connecting threaded pipe 83 is larger than that of the end far away from the connecting threaded pipe 83 The hole diameter of the extrusion hole is larger on the left and smaller on the right, which can ensure that the sealing rubber tube 12 can effectively enter the extrusion hole, so that the sealing rubber tube 12 will not interfere with the movement of the nut 13 to form wrinkles, and the formation of wrinkles It will increase the probability of oil leakage. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com