Injection molding rubber coating mold for rubber tubing

A technology of injection molding rubber covering and rubber tubes, which is applied to household appliances, tubular objects, and other household appliances, etc., which can solve the problems of lower production qualification rate, crushing of rubber pipe bodies, and unstable size of rubber covering deviation, etc., to achieve reduction Production cost, improving production efficiency, ensuring the effect of product appearance quality and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail through specific examples.

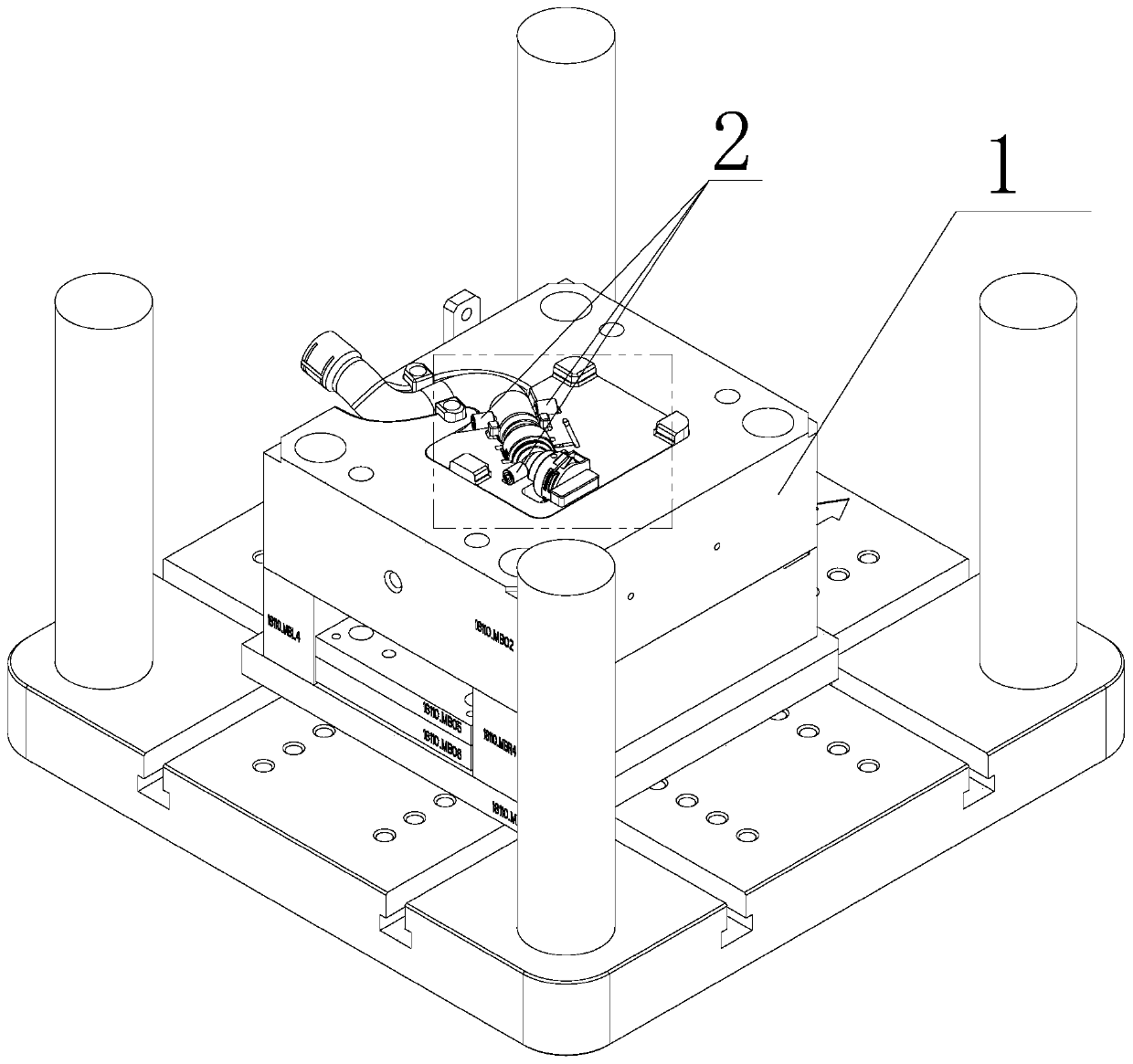

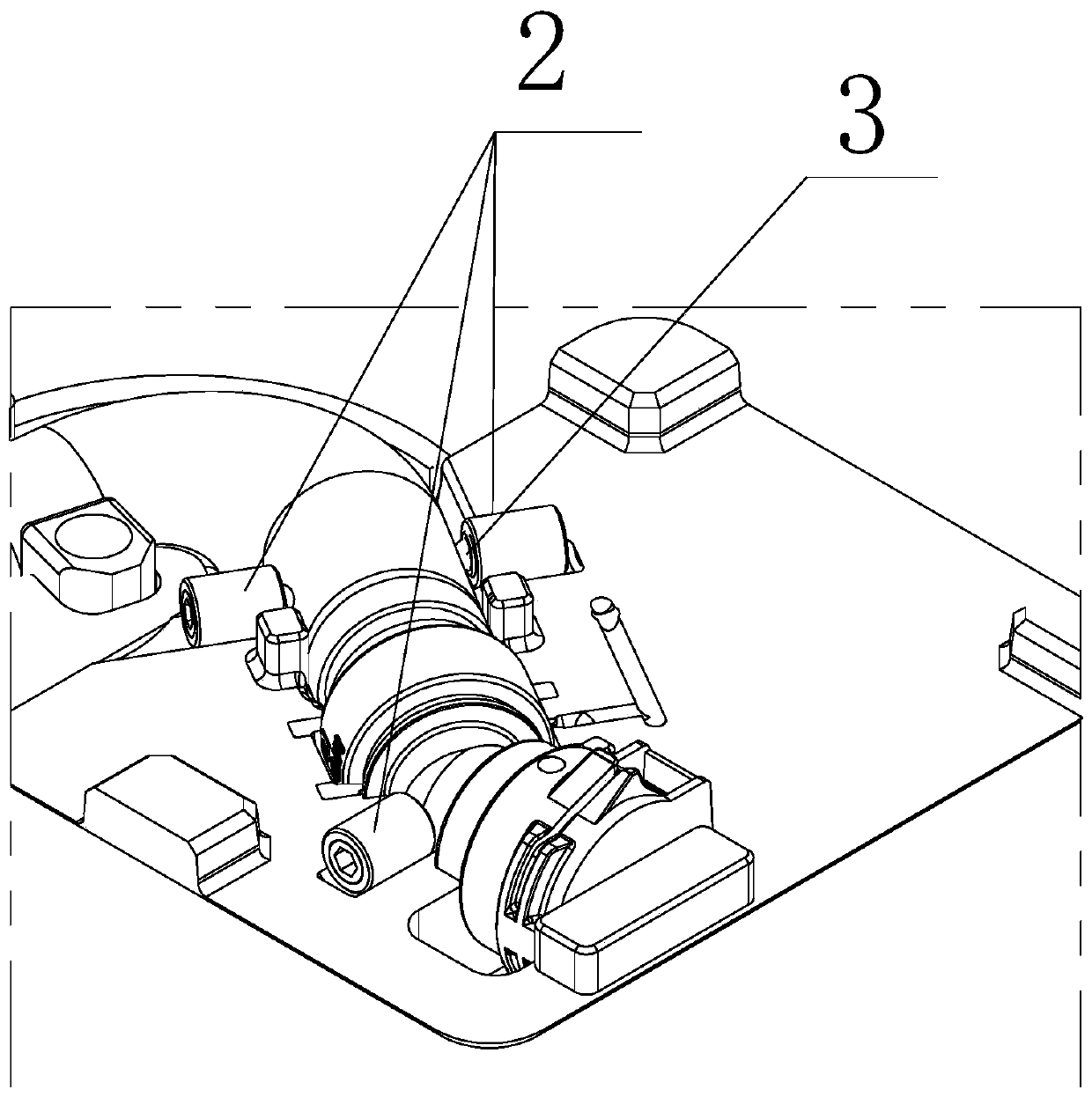

[0018] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a kind of injection-molded rubber-coated rubber tube mold proposed by the present invention; figure 2 for figure 1 A partial enlargement of the .

[0019] refer to Figure 1-2 , the present invention proposes an injection-molded rubber tube mold, comprising: a movable mold 1, which is provided with a mold cavity for putting the rubber-coated pipe fittings into, and on the movable mold 1 and is located on two sides of the mold cavity. A telescopic mechanism 2 that can expand and contract along the radial direction of the mold cavity.

[0020] In the injection molding process of the present invention, the joints of the injection molded parts and the glue to be glued are assembled and assembled directly into the mold cavity on the movable mold 1, and the telescopic mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com