A paper cup processing device and method thereof

A processing device and paper cup technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of poor artificial bonding effect and affecting the processing efficiency of the bottom of the cup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

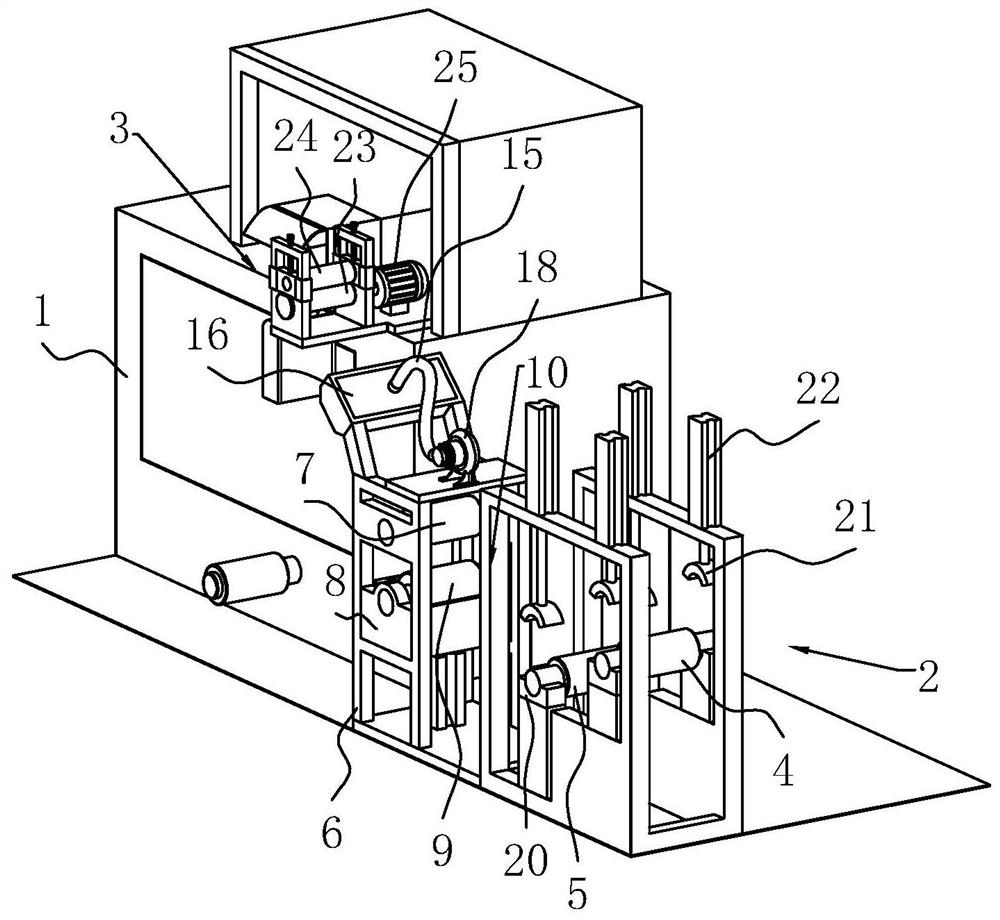

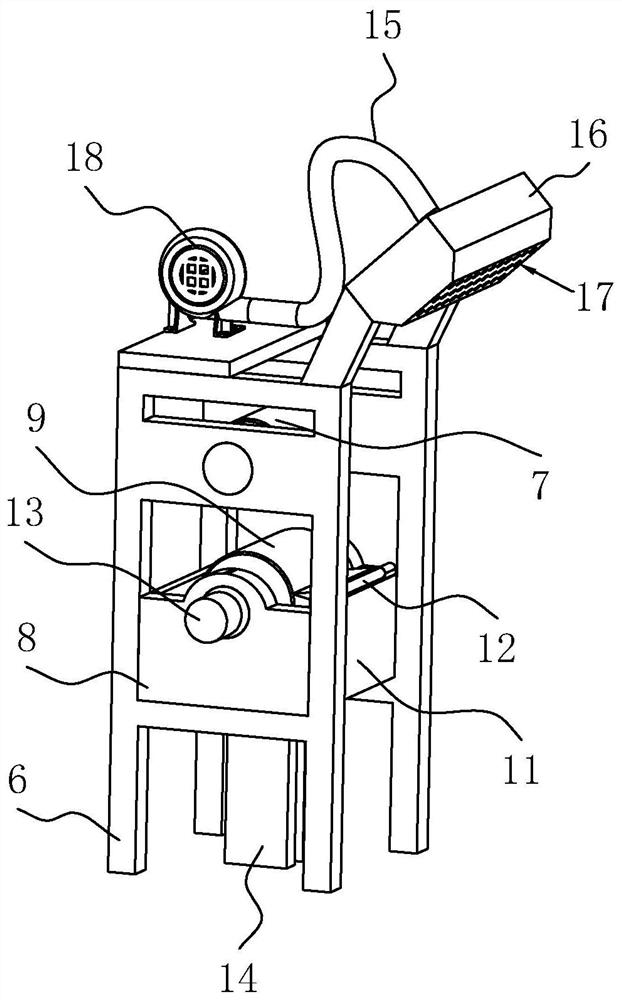

[0040] refer to figure 1 , is a kind of paper cup processing device disclosed by the present invention, including a frame 1, an unwinding mechanism 2, a paper feeding mechanism 3 and a cutting mechanism. Next, the paper cup at the bottom of the cup is conveyed to the cutting mechanism, which cuts the paper at the bottom of the cup into a cup bottom shape in the prior art.

[0041] refer to figure 1 and figure 2 , the unwinding mechanism 2 includes the unwinding roller 4 and the winding roller 5 that are all rotated with the frame 1, the unwinding roller 4 is located above the winding roller 5, and the vertical direction between the unwinding roller 4 and the winding roller 5 The distance is greater than the thickness of the cup bottom paper roll, and enough space is reserved to place the cup bottom paper roll; in order to facilitate the replacement of the unwinding roller 4 and the take-up roller 5, both ends of the unwinding roller 4 and the take-up roller 5 are fixedly co...

Embodiment 2

[0050] refer to figure 1 and figure 2 , is a kind of paper cup processing method disclosed by the present invention, comprises the following steps:

[0051] Step 1, the unwinding roller 4 is placed on the first semi-arc block 20, and the paper feeding mechanism 3 performs the paper feeding operation;

[0052] Step 2, paper splicing: place the splicing roller 5 on another first half-arc block 20;

[0053] Step 3, gluing: during the rotation of the upper rubber roller 9, the glue is coated on the upper rubber roller 9 circumferentially;

[0054] Step 4, bonding: the upper rubber roller 9 applies glue between the two layers of cup bottom paper;

[0055] Step 5, dry glue: the dry glue component is used to dry and bond the glue between the bottom paper of the cup.

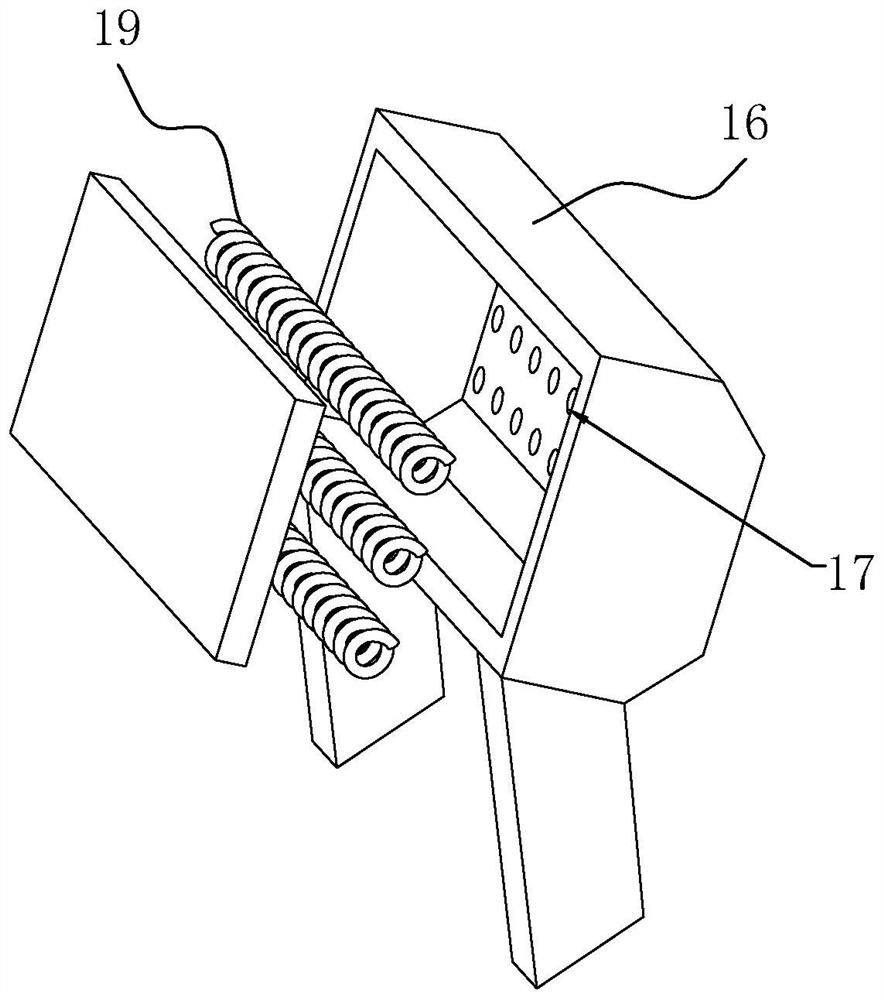

[0056] Place the unwinding roller 4 on the first half-arc block 20, the second cylinder 22 drives the second half-arc block 21 to move towards the first half-arc block 20, and the rotating shaft is located at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com